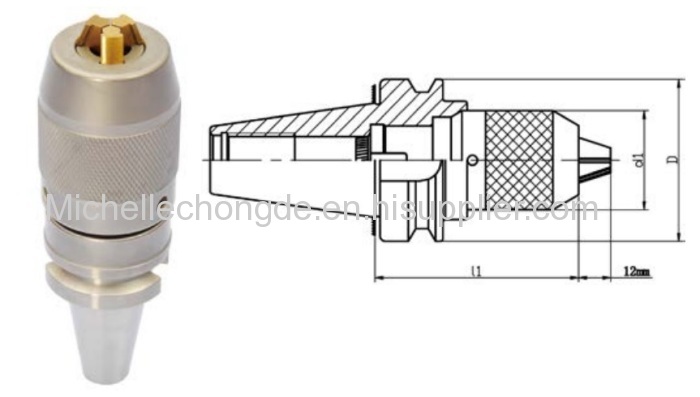

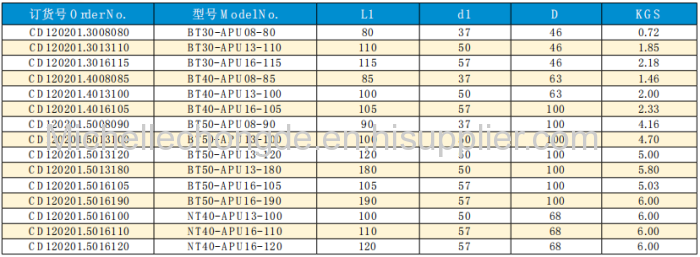

High Accuracy CNC APU Drill Chuck Holder with BT Shank

| Min. Order: | 3 Piece/Pieces |

|---|---|

| Payment Terms: | Paypal, T/T, WU, Money Gram |

| Supply Ability: | 20000pcs/month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Jining, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | BT30/40/50-APU13/16 |

|---|---|

| Type: | Drilling Tool |

| Machine Type: | Drilling Machine |

| Brand Name: | Chongde |

| Material: | 20Crmnti |

| Hardness: | 56~58 |

| Run out: | 0.005mm, 0.008mm |

| balanced: | G6.3 or G2.5 For choose. |

| Carbon Depth:: | >0.8mm |

| Production Capacity: | 20000pcs/month |

| Packing: | plastic box |

| Delivery Date: | 15~20 days |

Product Description

Product Description

Features:

1.Jaws titanium, improve the wear resistance,surface coating.

2.Integrated design of the rob and collet, can avoid the collet and rob separate.

3.High accuracy,strong grasp force, and high stability.

4.Self-tightening, grasp the collet slightly, when drilling, grasp force is enhancing with the torque increasing and develop.obvious strong grasp force to prevent the drill remove.

Advantage:

1.Material:20CrMnTi,Hardness:56-58HRC.

2.Carbon depth:>0.8mm.

3.Integrated design of the rob and chuck slightly,when drilling,grasp force is enhancing with the torque increasing and develop obvious strong grasp force to prevent the drill remove.

4.Coating surface enhance surface hardness durability,anti-rust and anti-corrosion better,precison more stable,surface more smooth and appearance more nice.

Attaching importance to the reserch and products,we employs many experienced and skilled technicians,so that precision machining can be made according to samples or drawings.

Surface roughness is reduced ,precision stability improved.

The collet chuck surface uneven texture,after polishing,the surface roughness can be leveling ,smooth and shining surface.At the same time filling surface pores scratches and other surface defects,thus improve the fatigue strength,corrosion resistance increase.

Don't influence precision.

Chuck surface is coated ,the layer is evenly ,Chemical plating solution dispersion degree of almost 100%,nickel layer is thin ,thickness is about 3u-5u,this special coating can reduce Spindle abnormal wear and tear ,Don't influence precision.

Anti-rust,anti-corrosion,durability better.

Coating adhesiion strong,enhance hardness,and anti-rust better in different surroundings,such as a cid,alkali,ammonia,salt etc.Overall nickel coating ,including inside and outside cone,even if you do not take any anti-rust actiions ,it will not rust either,don't influence processing precision and spindle .Improve cleanness,precision more stable,surface more smooth,feel more comfortable and appearance nicer .

Our service

I Fast reply

II Favourable price

III High quality products

IV Fast delivery

V Good after-sales service

1.Are you factory or Trade Company?

We are industry and trade integration.

2.Could you supply samples?

Yes ,free samples for some products.

3.Where do you export?

The whole world.

4.Could you produce non-standard products?

Yes ,we can .Please supply samples or drawing.

5.What are the shipping ways?

By intemational express,by air ,by sea are all OK.

6.Do you have minimum order quantity?

Conventional Products don't have.The minimum order quantity of non-standard products is 50pcs.

7.What's your delivery time?

Less than 25 days after order confirmed.