Slag ash removal slurry pump series of ZGB for gold mine

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 200tons per month |

| Place of Origin: | Hebei |

Company Profile

| Location: | Shijiazhuang, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service, Association |

Product Detail

| Model No.: | 80ZGB |

|---|---|

| Means of Transport: | Ocean, Air |

| Model Number: | ZGB Series slurry pump |

| Structure: | Single-stage structure |

| Power: | Electric |

| Application: | Ash, mining slurries |

| Color: | Any |

| Material: | High chrome alloy |

| Warranty: | 1 year not include spare parts |

| Place of origin: | China |

| Production Capacity: | 200tons per month |

| Packing: | Standard export packing or plywooden case |

| Delivery Date: | 20 working days |

Product Description

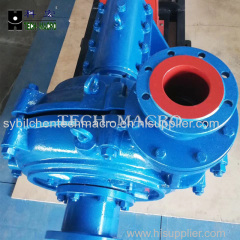

Slag ash removal slurry pump series of ZGB for gold mine coal mine copper mine

The type ZGB(P) pump is of horizontal single-stage, single-suction, cantilever, double-casing, centrifugal slurry pump. Among them, the ZGBP pumps are for stage 3 or 4 pumps in multi-stages. The pump is suitable for handling abrasive and corrosive slurry, widely used in electric power, metallurgy ,mine, coal, constructional material and chemical industry departments especially for removing ash and sludge in electric power station.

Technical Features:

· Large capacity; wide flow channel; high head; high efficiency; energy saving; long service life of wear parts; stable performance; easy maintenance.

· Advanced modern CAD(computer aided design), good hydraulic performance; good performance of NPSH; low wear rate.

· The pump adopted horizontal split oil lubricated bearing, with two sets of cooling system, to ensure the pump operating safely.

· The pump discharge can be positioned to 8 directions at intervals of 45 degree.

· Packing combined expeller and mechanical seal are optional, either of which ensures zero leakage.

· The inlet is horizontal. And the pump runs clockwise viewing from the drive end.

· The wet parts use wear-resistant materials to enlarge service life.

· The pumps can be installed in multi-stages under the allowable max. Pressure, and the max. working pressure allowed is 3.6 MPa.

· The wet parts of the ZGB and ZGBP pumps of same discharge diameter can be interchangeable.

Typical Application:

· Ore processing

· Removing ash and sludge in power plant

· Transferring lime-ash in power plant

· Metallurgy

· Building materials

· Ash removal of sea water

· Salt spray electronic chemistry

· Other anti-abrasive anti-corrosive working conditions

Model:

80 ZGB (P)

80--discharge diameter (mm)

Z--slurry pump

G--high head

B--series code

(P)-mufti-stage in series (3-4 stages) (not marked for 1, 2 stages)

Materials:

Metal:

Wear-resistant metal: A61, A05, A07, A11, A01

Anti-abrasive, anti-corrosive metal: A49, A33

Anti- abrasive metal: A22, A23, A25

Other optional metals or alloys: Duplex stainless steel, stainless steel, nickel cast iron, brass, bronze, etc.

ZGB slurry pump structure:

Performance chart

| Capacity: | 210-1100m3/h |

| Head: | up to 98.4m(328ft) |

| Discharge Diameter: | 390-760mm |

| Max. Particle Size: | 90mm |

Our Services