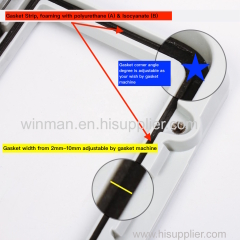

Electric Cabinet Pu Foam Sealing Gasket Polyurethane

| Min. Order: | 5 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 5000 |

| Place of Origin: | Shanghai |

Company Profile

| Location: | Shanghai, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Brand Name: | WINMOON |

| Viscosity at 23°C: | 30000 - 50,000 mPa*s |

| Density without air loading: | 1.25-1.35g/cm3 |

| Accept Color: | Black,Grey,Red,Blue,Green |

| Mixing ratio: | 5 : 1 |

| Hardness: | 12 Shore-A |

| Tensile strength: | 0.3 MP |

| Temperature resistance (short-term): | ~ -60 - +190 °C |

| Tack-free time: | 4-6 min |

| UV-Resistance: | no damage Xenon lamp |

| Full hardening: | ~24H |

| Production Capacity: | 5000 |

| Packing: | L1200*W1200*H900mm |

| Delivery Date: | 10days |

Product Description

PROCESSING information:

WM201915 systems are processed using two-component mixing and metering machines. The recommended processing temperature is + 23 ± 5 °C. Most of the WM201915 components can be stored in the original packaging and for at least 6 months at temperatures between + 10 and + 40 °C.

Mixing time: is the time period in which the A and B components are mixed.

Reaction time: is the time period in which the glue foam system begins to react(after approx. 15-60seconds*).

Rise time: is the time period in which the glue foam system expands to form the seal body(after approx.15-180seconds*).

Tack-free time: is the time after which the sealing surface of the glue foaming system is tack-free at room temperature and can be touched without causing damage(after approx. 2-20minute*).

Assembly time: is the time point after which glue foaming systems can bear loads or the sealed components can be assembled(after approx. 20minuts-12hours*).

The formula has been successfully researched for many years.

Lead your electrical cabinet to achieve the best tightness, IP67. The A-component (polyol) determines the chemical and physical properties of the sealing foam. The B-component (isocyanate) initiates the chemical reaction and influences above all the reaction speed.