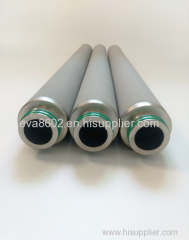

SS316L Sintered Filter Cartridge backwash reusable bubble diffusion and gas purifucation

| Min. Order: | 10 Piece/Pieces |

|---|---|

| Payment Terms: | Paypal, L/C, T/T, WU, Money Gram |

| Supply Ability: | 50000pcs/month |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Baoji, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Means of Transport: | Ocean, Air |

|---|---|

| Structure: | Others |

| Function: | Purification Filter |

| Brand Name: | Along |

| Size: | customized |

| technology: | high temperature sintering |

| materials: | 316L stainless steel powder |

| application: | bubble diffusion,chromatographic column, gas sparger, electrode materials, filtration and separation |

| Production Capacity: | 50000pcs/month |

| Packing: | Packed in cartons or wooden cases |

| Delivery Date: | Packed in cartons or wooden cases |

Product Description

1. Specification of stainless steel sintered porous materials

| Material | Filter Rating | Porosity | Penetrability | Working pressure | Operating temperature | Shape | specific surface area |

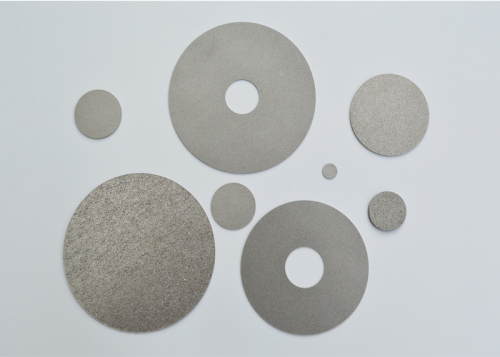

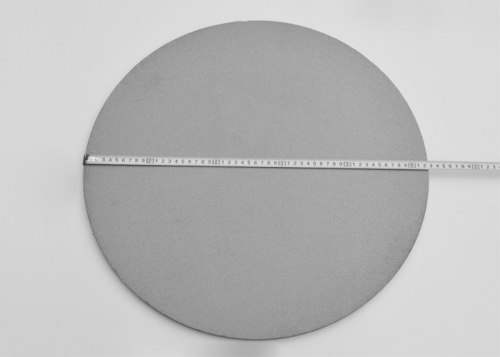

| 304,304L,316, 316L Stainless steel powder | 0.5um-70um | 30-45% | 3-1300M³/M²hKPa | 3.0MPa | 600℃ | Round Disc, Sheet,Tube,Round Bar,cap. | 10-40cm²/cm³ |

| Production | (Diameter)Length | (Diameter)Width | Thickness | Customized |

| Sintered porous round discs | φ5-φ300mm | φ5-φ300mm | 0.5-10mm | Yes |

| Sintered porous sheets | 5-300mm | 5-300mm | 0.5-10mm | Yes |

| Sintered porous tubes | 100-1200mm | φ20-φ200mm | 1-10mm | Yes |

| Sintered porous cartridge | 100-1200mm | φ20-φ200mm | 1-10mm | Yes |

2.Application of stainless steel sintered porous materials

According to its physical and structural characteristics, stainless steel sintered porous materials are mostly used in the fields of noise elimination, filtration and separation, fluid distribution, flow limiting, capillary core and so on.

1) Chemical raw material production process in addition to impurity filtration, material decarburization filtration and fine filtration.

2) Ultrafiltration, RO, EDI system security filtration in water treatment.

3) Food and beverage industry finished product clarification filtration.

4) Filtration and recovery of precious metal catalyst in petrochemical industry.

5) Precision filtration of liquid raw materials, products and pharmaceutical intermediates in the chemical industry.

6) Reverse osmosis security filtration in the field of water injection filtration.

7) Gas purification of steam, compressed air deoiling purification.

8)Medium purification and flow limitation for pneumatic components, lubricants, fuels and hydraulic pressure systems.

9) Chemical dye industry of high - temperature decarburization.