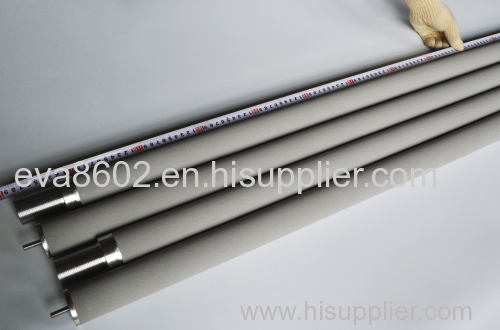

Pure titanium sponge sintered porous filter tube/rod/cartridge/cylinder

| Min. Order: | 10 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | Paypal, L/C, T/T, WU |

| Supply Ability: | 5000pcs/month |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Baoji, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | customized |

|---|---|

| Structure: | Cartridge Filter |

| Material: | Others |

| Function: | Purification Filter |

| Brand Name: | Along |

| materials: | titanium powder |

| Size: | customized |

| technology: | high temperature sintering |

| application: | bubble diffusion,steam and hot gas cleaning, gas sparger, electrode materials, filtration and separation |

| industrials fields: | chemicals, food and beverage, bio-pharmaceuticals,new energy, aerospace field |

| Production Capacity: | 5000pcs/month |

| Packing: | Packed in cartons or wooden cases |

| Delivery Date: | 5-30days |

Product Description

2.Properties of titanium sintered porous materials:

1) Pore diameter uniformity, pore stability, high separation efficiency.

2) High porosity, low filtration resistance and high permeability.

3) Good chemical stability, corrosion resistance , oxidation resistance.

4) Morphological stability, no particle shedding, comply with food hygiene and pharmaceutical GMP requirements.

5) Good mechanical properties, low differential pressure, large flow.

6) Strong anti-microbial ability, does not interact with microorganisms.

7) Online regeneration, easy cleaning, long service life.

8) Excellent biocompatibility, can be widely used in biological, food, pharmaceutical, medical industry.

9) Excellent electromagnetic shielding performance.

10) Good damping and shock resistance.

2.Application of titanium sintered porous materials:

Titanium sintered porous materials are mostly used for filtering materials,electrodes,heat transfer materials,catalyst carrier materials,noise cancelling materials according to their physical and structural properties.

1) Decarburization filtration of pharmaceutical liquids.

2) Electrolytic gas industry precision filtration, gas distribution.

3) The medical industry makes biological implants.

4) Water treatment industry odor sterilization filtration and ozone aeration.

5) Clarification and filtration in food and beverage processing.

6) Prefiltration of reverse osmosis system for electronics industry.

7) Terminal filtration of petroleum products in petrochemical industry and filtration of carbonic alkali liquid in chemical industry.

8) High pressure air filtration in aerospace industry.

9) Filtration and recovery of precious metal catalyst in fine chemical industry.

10) The electrode matrix of a fuel cell.

11) Catalyst carrier in gas and liquid catalytic reactions.