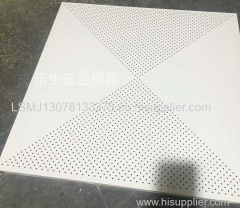

300mm*300mm Aluminium ceiling tile cutting forming machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | EXW |

| Payment Terms: | T/T |

| Supply Ability: | 6-8pieces/minutes |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Foshan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | lesheng 02 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | lesheng |

| item name: | 300 ceiling making macine |

| keyword: | square ceiling forming machine |

| advantage: | full automatic |

| function: | ceiling angle cutting and bending |

| mold: | DC53.D2 |

| ceiling size: | 300mm*300mm |

| ceiling material: | aluminium, steel |

| Brand: | lesheng |

| Origin: | China |

| service: | egineer can service machine oversea |

| Production Capacity: | 6-8pieces/minutes |

| Packing: | PE film wooden box |

| Delivery Date: | 90 days |

Product Description

300mm*300mm Aluminium ceiling tile cutting forming machine

Company introduce:

LESHENG is specialized in mold and Automatic clip in/lay on /lay in ceiling tiles making machinery for more then 30 years with a professional R&D technical team. They can design the cold die mold and ceiling tiles making line as per customer's requirements. Automatic line with punching ,cutting ,forming devices. Low labour cost, high output.

Main Technical Parameter

Ceiling tiles production line -300

Automatic perforating and manual 4 sides edge forming

Below is main components specification of LESHENG300*300 ,Automatic aluminium complete production line for lay in ceiling ,clip in ceiling.

1.Decoiler

a.Hydraulic press

b.loading capacity :3T

c.speed:adjustable

d.Inner diameter:400m-500m

e.largest outer diameter:1500m

f.Weight:1000kg

g.measurement:(Length)1.7m*(Width)1m*(Height)1.5m

2.Straightening machine

a.Material width can be less then 750m, thickness:0.3-1.5mm

b.Straightening by 21-Axis,with auxiliary shaft

c.Motor:380V,2.2w.rotating fastest speed:40m/min

d.Measurement:(Length)1.6m*(Width)1m*(Height)1.2m

4 Auto feeder machine

a.Sevor motor:220V.0.75KW.

5. punching machine

a. punching machine or as per your requirement

b.Hydraulic press

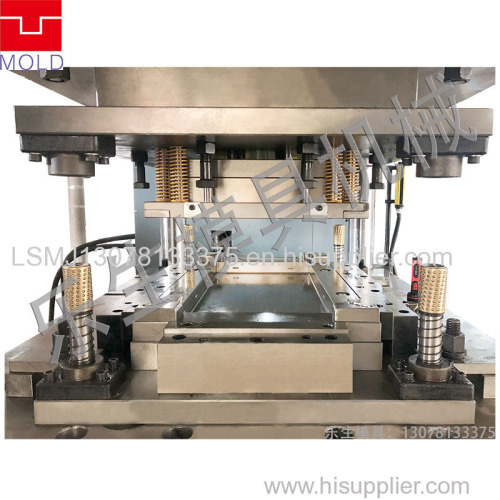

6.cutting and forming machine

a.Advantage:double cylinder .The vice cylinder cutting off material and corner. Main cylinder form the ceiling. Cutting and forming in one step.

b.Vice cylinder capacity 20T, main cylinder 30T, the 2nd layer cylinder 10T.

c.Motor:380V,11kw,capacity:80T

d.Output:6-8pcs/min

e.weight:7000kg

f.Measurement:(Length)1.4m*(Width)2.2m*(Height)2.4

7.Conveyor

Transmit material smoothly.

8.turn over device

On the coveyor belt have one ture over reactor, it transit aluminium sheet automatically

9.machanical pusher

Operated by gasdynamic .Sucked up the cutted aluminium sheet into forming machine,then forming machine stamp it to be ceiling.

10.MOLD

Machine with Lesheng own design mold. Can OEM as per your requirement. Mold adopt high quality DC53,D2,SKD11. Long service life and high quality.

Normal Packaging details:

Main machine are packed by water proof plastic film

Machine spare parts are packed by wooden box

PLC control box and whole making line control box are packed by wooden box with water proof coverage

Motor pump packed by woooden box with water proof coverage

Our services

1.Professional LS technician can be sent for installation and do operation trading oversea.

2.Guarantee for spare pats is three months

3.Trading provided free trading in our factory

4.AliTradmanager is online 24 hours.welcome to contact us anytime.

If your have any question about our ceiling making line or mold, please feel free to contact us. Hope you have chance to cooperate with you.

payment term:

1.Payment Term: 40% Advanced Payment, Pay Balance After Inspection Before Delivery by TT.

2.Delivery Time:90 days from advanced payment.

3.Shipment Term: EXW FACTORY,China.

4.Machine Color : as per customer

5.Packing: PACKING: SEA GRADE PACKAGE.

6.Warranty: Warranty period is one year after the machine delivery.

Factory: FOSHAN LESHENG metal mold machinery factory

Ali mamager: fslsmetal

Contact:liang lesheng