aluminium ceiling tile making machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | EXW |

| Payment Terms: | T/T |

| Supply Ability: | 6-8pieces/minutes |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Foshan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | lesheng 01 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | lesheng |

| item name: | 600 ceiling making macine |

| keyword: | square ceiling forming machine |

| advantage: | full automatic |

| function: | ceiling angle cutting and bending |

| mold: | DC53.D2 |

| ceiling size: | 600mm*600mm |

| ceiling material: | aluminium, steel |

| Brand: | lesheng |

| Origin: | China |

| service: | egineer can service machine oversea |

| Production Capacity: | 6-8pieces/minutes |

| Packing: | PE film wooden box |

| Delivery Date: | 90 days |

Product Description

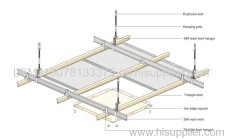

CNC metal sheet bending machinery China machinery equipment for false ceiling tile

Machine introduction:

This production line is for making 600*600 clip in /lay on ceiling tile(change mold). Machine feature:hydraulic press,full automatic.

160T press machine for coner cutting and edge bending at same time. Output is about 6-8 pieces/minutes.

Machine main components:

Decoiler-leveling machine-hydraulic press for cutting bending-conveyor

Products Description

Item Name | metal ceiling tile bending machine production line | Remark |

Future | fully auto, high speed | OEM accepted |

Max Production Size | 600mm*600mm | OEM accepted |

Perforation holes Size | Φ 1.5mm/1.8mm/2.3mm/2.5/3.0mm,various sizes | OEM accepted |

Decoiler | 5T,380V,50HZ | Manual Loading |

Leveling machine | 3kw ,380V | 1unit |

Servo feeder | high precision ,tolerance is (±0.2mm). | 1unit |

Mold type | Punching mold,cutting mold,bending mold | 1unit seperately |

Hyd. Press Hydraulic Motor Power | 380V,200T oil press | 1unit |

product capacity | 6-8 PCS/MIN | High speed |

Electrict system | Panasonic/ Mitsubishi | high quality |

Whole line | Only about 20 meters |

Machine maine componet details

1.Decoiler

3. Leveling machine

4.Hole punching machine

6.High precision servo feeder

8.200T hydraulic press molding machine

9,80T high speed cutting machine

10.Advabced machanical arm

11.Conveyor

12. Good quality control box

Lesheng progressive mold for cutting bending

Integrated ceiling molding mold adopt high quality raw materials, mold steel adopt international standard A3 material.. Mold knife is Japan SKD11 mold steel.. make sure mold precious and lifetime. It's the first choice for the old and new customer. High qualityand favorable price can save lots of long production runs cost for customer, Increasing marketing competition. Suitable for producing high quality, high quality material, premium brands aluminum ceiling, aluminum gusset plate, integrated ceiling panel. Factory can OEM mold for various ceiling design. Now our ceiling mold 300*300, 600*600, 300*600, 400*1200, 600*1200 have been widly used in home and abroad.

Packaging and shipping:

Normally we packed machine with the PE film, and the important pats of machine and mold will packed in the wooden box.

Company Profile

Foshan Nanhai District Le Sheng metal products factory was established in 1999. It is located in Nanhai District, Foshan, Guangdong province. It is adjacent to the South Yuen area. It is also located near the FoShan 1 ring road . The traffic is very convenient, the company has a workshop area of 5000 square meters. LeSheng company is a professional R&D,all kinds of cold stamping die, we have a professional design team and High precision advanced processing equipment,strong production technology and quality assurance.

After more than 20 years of research and development, Le Sheng metal products factory has a rich experience and professional design team. Aiming at the growing demand for products at home and abroad, our company has designed and developed a variety of automatic production lines of metal building materials ceiling,like 300*300/600*600 sheet full automatic molding production line, the grille automatic production line and all kinds of sheet metal production line die equipment, etc., the company also produces various kinds of sheet metal parts for the customers.

All kinds of hardware moulds produced by our factory are trusted and recognized at home and abroad by high quality and complete after-sale service. The mould is sold well and sold to more than 20 countries such as Europe and America.

"Quality based, Customer first". Le Sheng is sincerely willing to move forward with you and Warmly welcome to our factory

Welcome customer to contact us anytime!