China Full Automatic Apg Machine AVOL1010 Produce CT SF6 Cover Circuit Breaker Sealed Pole

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | T/T |

| Supply Ability: | 10 Sets per month |

| Place of Origin: | Jiangxi |

Company Profile

| Location: | Pingxiang, Jiangxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Service |

Product Detail

| Model No.: | AVOL-1010 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Model Number: | AVOL-1010 |

| Color: | customizable |

| Size(mm): | 6560*1020*3205 |

| Weight(KG): | 7350(6850) |

| Heating plate size(mm): | 800*600 |

| Clamping force(KN): | 250 |

| Heating power(KW): | 24 |

| Warranty: | 1 year |

| Speed of clamping close(m/min): | 3.1(2.4) |

| After-sales service provided: | Engineers available to service machinery overseas, Online support, Video technical support, Field maintenance and repair |

| Production Capacity: | 10 Sets per month |

| Packing: | using plastic film then into container |

| Delivery Date: | 45 days after place an order |

Product Description

Product Details

| Brand Name: | VOLMET | Model Number: | AVOL-1010 |

| After-sales Service Provided: | Engineers available to service machinery overseas | Port: | Any ports in china |

| Place of Origin: | China | Condition: | New |

| Applicable Industries: | electrical power insulation | Packaging Details: | thin film and wooden box |

Product Description

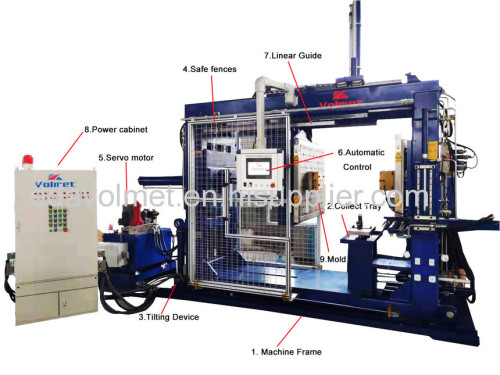

1.AVOL-1010 Full Automatic APG clamping machine:

1). Application:

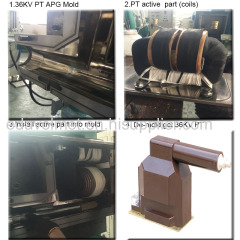

Used for producing epoxy resin components from 11-36KV, such as CT, PT, insulators, bushings, spout,SF6 cover, GIS, LBS etc.

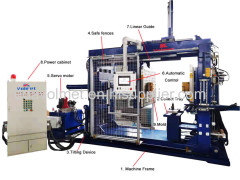

2).Full automatic control system with touch screen, Realize one-button run machine:

- Automatically clamping mold;

- Automatically adjust injection pressure and injection time

- Automatically tilting machine

- Automatically hold pressure and hold pressure time

- Automatically alarm and de-mould

- (install coil and inserts, take products from mold, clean mold by manual)

3).Advantages:

- Reduce work injure

- High efficiency

- Ensure product quality

- Save labor cost, 1 worker can operate 2-4 machines

- Low requirement for workers

- Remote control machine (optional)

2.Machine introduction:

Machine frame: Tempering and finish machinery →Improve strength,avoid deformation,ensure high precision,avoid mold leakage

Collect Tray → Keep clean,protect lower core.

Tilting device → vertical and horzontal tilting

Safe fences→ avoid work injure

Servo motor→ save energy, low noisy, easy maintance

Full automatic system→ programmable, full automatic.save receipt,remote control

linear guide →ensure clamping stability

Power cabinet→

APG Mold →Volmet supply mold and technique training overseas.turn key project.

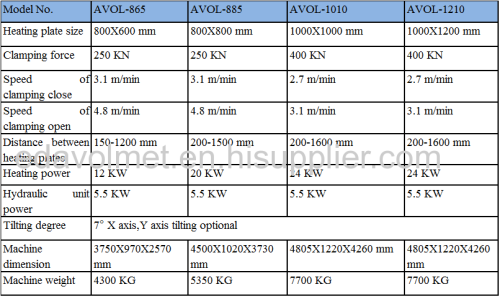

3.Technical Datas:

4.production process:

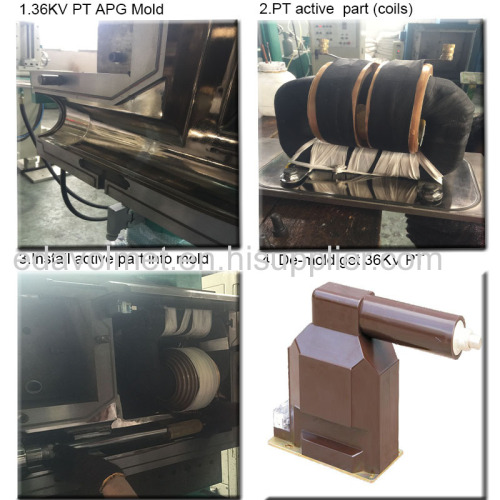

1).36KV potential transformer production process:

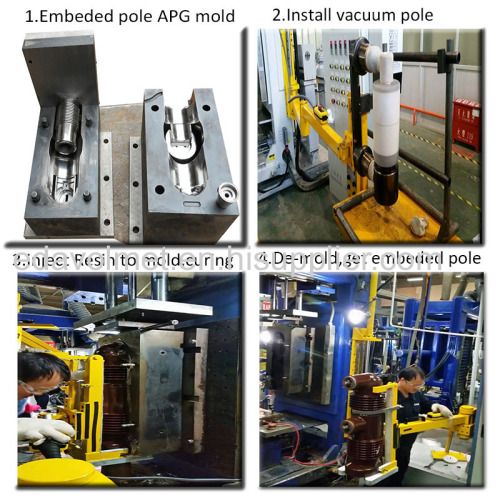

2).Embedded pole production process:

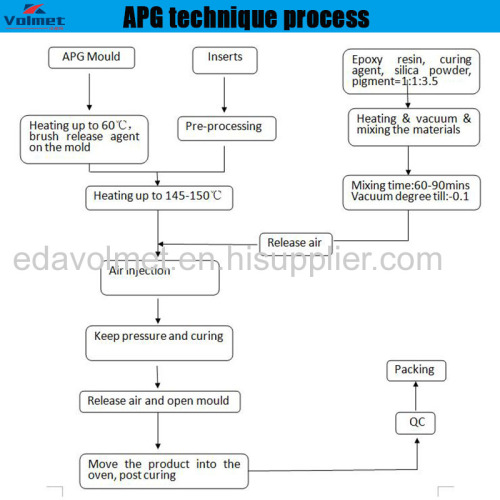

5. APG machine process:

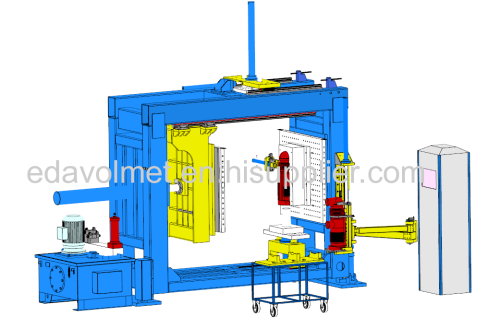

1.Milling machine frame: each side of frame will milled by vertical lathe machine,enasure installation precison,avoid mold leakage.

2.Heating treatment for machine frame: Do 3 times of heat treatment for machine frame after welding. release inter stress,reduce machine deformation in the future.