400W Maglev Wind Turbine

| Min. Order: | 3 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 1000set/year |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Other |

Product Detail

| Model No.: | FQ-400W |

|---|---|

| Means of Transport: | Ocean |

| Type: | Others |

| Pipe Material: | Others |

| Application: | Others |

| Brand Name: | Ferra |

| Green Energy Generator: | Wind turbine generator |

| Wind Energy Generator: | Wind Generating Equipment |

| Family Wind Generator: | Wind & Solar Hybrid System |

| Fixed Baldes Wind Turbine: | Flad Balds |

| Production Capacity: | 1000set/year |

| Packing: | Wooden Case |

| Delivery Date: | 10 days |

Product Description

FQ-400W Maglev Wind Turbine

I. System advantages

1. Adopted maglev generator technology to reduce the starting resistance coefficient of wind turbine , to make it can be starting working under low wind speed of 1.5-2m/s

2. Running Smoothly no vibration, Low noise design

3. Low maintenance rate and low failure rate

4. Aluminum alloy blades with long service life

5. Humanized mounting flange design, convenient for installation and maintenance

6. Adopted the maximum power tracking intelligent microprocessor control to effectively regulate the current and voltage

7. Advanced aerodynamics design

8. Unique waterproof, moisture-proof, anti dust and salt spray design.

9. High strength, corrosion resistant special aluminum alloy materials

II. Technical Parameters

| Model | FQ-400W |

| Rated Power | 400W |

| Max. power output | 480W |

| Wind wheel diameter | 1.42m |

| Wind wheel height | 0.9m |

| Blades quantity | 3 |

| Blades Material | Aluminum Allow Blades |

| Start wind speed | 1.5m/s |

| Cut-in wind speed | 3 m/s |

| Rated wind speed | 11m/s |

| Security wind speed | 45m/s |

| Output voltage | 12V/24V |

| Net weight | 30kg |

| Motor type | Three phase AC permanent magnet synchronous generator |

| Control system | Over-speed automatic unloading Steady speed control Three phase short circuit brake |

| Lubrication method | By grease |

| Working temperature | -40ºC - 80ºC |

III. Disassemble drawing

IV. Products Details

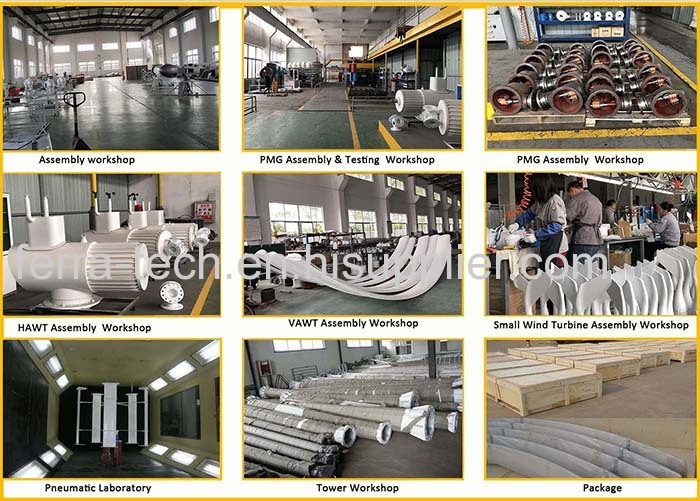

V.Company Workshops and Production Capability

VI. Project Case