Segment Motor Magnet supplier

| Payment Terms: | L/C, T/T |

|---|---|

| Supply Ability: | 500 tons |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Production Capacity: | 500 tons |

|---|---|

| Packing: | Corrugated box, Polywood pallet, Polywood case |

| Delivery Date: | 10-20 days after receipt of payment |

Product Description

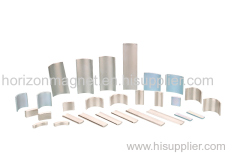

arc shaped Neodymium magnets

wind generators Segment Motor Magnet

Servo motors Segment Motor Magnet

Segment or arc shaped Neodymium magnets are widely used instead of expensive radial rings in electric motors.

Horizon have been focusing on the development and production of high end series of NdFeB rare earth permanent magnets, which are widely used in permanent magnet motors and generators.

Due to their advantage, NdFeB rare earth magnets have become one of the most important components of permanent magnet motors and generators, whose performance and life time mainly depends on the quality of magnets. Generally speaking, the working environment to motors and generators is very harsh. In order to adapt to this working environment, we have been devoting ourselves to research and develop NdFeB rare earth magnets specially used for permanent magnet motors and generators since its foundation. For this application, the magnets are available in a wide range of shapes such as block, ring, segment, loaf, wedge, etc.

Currently we are producing serials of high end grades, like H, SH, UH, EH and AH for NdFeB with following three characteristics:

High intrinsic coercivity Hcj: high to >35kOe (>2785 kA/m) which increases magnets demagnetizing resistance

Low reversible temperature coefficients: low to α(Br)< -0.1%/ºC and β(Hcj)< -0.5%/ºC which increases magnets temperature stability

Low weight loss: low to 2~5mg/cm2 in HAST testing condition: 130ºC, 95% RH, 2.7 ATM, 20 days which increases magnets corrosion resistance

Although the low weight loss material improves its corrosion resistance, the coating is still often required by customers. If customers require coating, we suggest magnets be phosphated or passivated. However, more and more customers change to use magnets without any coating, because uncoated magnets have much better glue cohesiveness than coated magnets.

stepper motors Segment Motor Magnet Applications:

Servo motors, elevator motors, traction motors, stepper motors, disc type motors, wind generators, etc.

Size:

Normal Size Range: L (Length): 1~180mm, W (Width): 3~180mm, H (Height): 1.5~100mm

Maximum Size: L50 x W180 xH80mm, L180 x W80 xH50mm,

Minimum Size: L1x W3 x H2mm

Orientation Direction Size: Lower than 80mm

Tolerance: Generally +/-0.1mm, Particularly +/-0.05mm

Segment Motor Magnet Machining Method:

Generally the segment requires grinding and EDM cutting from the big block. Sometimes, the approximate final shape achieved after the EDM cutting needs processing with a shaped diamond grinding wheel which provides the precise dimensions and speeds up the machining process. Prior to coating, the small segment needs vibration tumbling and the big segment needs manual chamfering.

Main Test Items Prior to Delivery:

In order to ensure NdFeB magnets to meet requirements, we main test following items: size, weight loss, magnetic properties, flux, flux density, angle deviation, magnetic loss, appearance, coating thickness, corrosion resistance, etc.

More information please view here.