Block Neodymium Magnet supplier

| Trade Term: | FOB |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 500 tons |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Production Capacity: | 500 tons |

|---|---|

| Packing: | Corrugated box, Polywood pallet, Polywood case |

| Delivery Date: | 10-20 days after receipt of payment |

Product Description

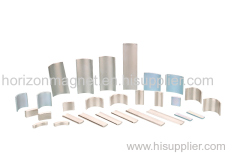

Block Neodymium Magnet

square Block Neodymium Magnet

rectangular Block Neodymium Magnet

Neodymium bar magnets Factory

Horizon supply Neodymium magnets in square and rectangular block shaped. Usually we call them magnetic blocks, Neodymium bar magnets or rectangular Neodymium magnets. The block magnets are always used in industrial markets and small blocks may be used as craft magnets.

Neodymium magnets known as NdFeB, Neodymium-Iron-Boron, Neo, NIB or Rare Earth Neodymium magnets, are the third generation of rare earth permanent magnets. They offer the highest energy product of any material today and are available in a very wide range of shapes, sizes and grades. These qualities have made NdFeB magnets preferable over the commonly used larger and less powerful Ferrite magnets.

Although the Curie temperature for NdFeB materials is 310-370ºC, some irreversible loss of output may be expected at even moderate temperatures. NdFeB magnets also have a moderately high reversible temperature coefficient of Br which reduces total magnetic output as temperature rises. Selection of NdFeB instead of SmCo, for example, is a function of the maximum temperature of the application, required magnetic output at typical use temperature and total cost of the system.

However, they are sensitive to oxidization and can develop corrosion, so they require surface protection like phosphate, passivation, Ni, NiCuNi, Zn, Epoxy, NiCuNi+Sn or others.

Characteristics:

Genuine Neodymium magnet, without La (Lanthanum) or Ce (Cerium) to destroy magnet quality

Outstanding magnetic properties – Br high to 14.5 kGs (1. 45T) and (BH)max high to 52 MGOe (414 kJ/m3)

High demagnetization resistance –maximum Hcj higher than 35 kOe (2785 kA/m)

High working temperature – maximum working temperature high to 230ºC

Wide range of grades with new ones regularly being developed – High magnetic properties, AH grades or Low Weight Loss materials and so on.

rare earth magnet Size:

Normal Size Range: L (Length): 1~180mm, W (Width): 0.4~100mm, T (Thickness): 0.4~120mm

Maximum Size: Rectangular: L180 x W80 xT60mm, Square: L100 x W100 xT70mm

Minimum Size: L1 x W1 x T0.4mm

Orientation Direction Size: Lower than 80mm

Tolerance: Generally +/-0.1mm, Particularly +/-0.03mm

Machining Method:

Generally the finished block of small dimension is sliced from the big block directly. If the dimension of one or two directions is large, for example >60mm, it should need grinding and EDM cutting, due to the limits of the slicing machine. If all three directions are too large, only grinding is enough. Prior to coating, the small block needs vibration tumbling and the big block needs manual chamfering.

Main Application:

Electric motors, wind turbines, pump couplings, chemical pumps, sensors, magnetic sputtering cathodes, magnetic assemblies, etc.

Main Test Items Prior to Delivery:

In order to ensure NdFeB magnets to meet requirements, we main test following items: size, weight loss, magnetic properties, flux, flux density, angle deviation, magnetic loss, appearance, coating thickness, corrosion resistance, etc.