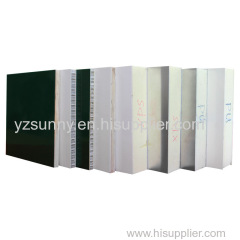

FRP panel truck body panel honeycomb panel sandwich panel

| Min. Order: | 100 Square Meter |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Supply Ability: | 40000 M2/month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Yangzhou, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Drive Wheel: | Others |

| Capacity (Load): | 1-10T |

| Condition: | New |

| Horsepower: | 150-250HP |

| L=16m: | W=2.9m |

| Production Capacity: | 40000 M2/month |

| Packing: | pallet/crate |

| Delivery Date: | 1 week |

Product Description

FRP skins are produced from the advanced continuous line, made of high-strength chopped strand mat, woven roving and high quality unsaturated resin.

Width: up to 3m

Thickness: 1.5mm to 3mm

Length: any length, to be customized, 60m/roll, 100m/roll, 150m/roll to be recommended

Lamination: chopped mats, woven roving or combination

Color: RAL number or to be customized

surface treatment: gloss/gloss, gloss/rough.

Packing: rolls on pallets or in crates

Lead time: 7 days.

Application: making sandwich panels, roof of dry box, commercial box, caravan trailer. greenhouses' ceiling.

Plastic honeycomb cored composite panels:

Made of prefabricated FRP skin, high-strength woven roving and plastic honeycomb sheets, bonding together under high vacuum pressure. The gelocatd surface are of food grade. Advantage: light weight, corrosion resistance, smooth and glossy surface, UV and weather resistance, easy to repair.

Thickness: 15mm, 18mm, 21mm

Application: dry box, commercial box, caravan trailer.

Plywood cored composite panels:

Made of prefabricated FRP skin, high-strength woven roving and plywood, bonding together under high vacuum pressure. The gelocatd surface are of food grade. Advantage: light weight, corrosion resistance, smooth and glossy surface, UV and weather resistance, easy to repair.

Thickness: 15mm, 18mm, 21mm

Application: dry boxes of trailers, front walls, rear door panels.

PU foam or XPs foam cored composite panels:

Made of prefabricated FRP skin, high-strength woven roving and PU foam or XPS foam, bonding together under high vacuum pressure. The gelocatd surface are of food grade. Advantage: strong, corrosion resistance, smooth and glossy surface, UV and weather resistance, easy to repair.

Thickness: from 30mm up to 130mm

Application: insulated truck bodies, refrigerated truck bodies, commercial vehicles, motor home, utility vehicles, catering trucks