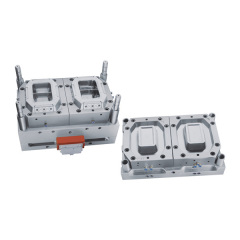

Thin wall mould automobile accessories mould

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 30sets/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Taizhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Means of Transport: | Ocean, Air |

|---|---|

| Product Material: | Plastic |

| Product: | Vehicle Mould |

| Shaping Mode: | Plastic Injection Mould |

| Production Capacity: | 30sets/month |

| Delivery Date: | 30 days |

Product Description

Product Name: Thin wall mould

Product number:

Mold Material: 45 #, 50 #, P20, H13, 718, 1730, 2738, etc.

Number of Cavity: Single Cavity Mould

Runner type: hot runner or cold runner

Design software: UG, PRO-E, CAD, CAXA, etc.

Mould life: 500000-1000000 times

Main processing equipment: CNC milling machine, fine engraving machine, EDM, wire cutting, grinding machine, drilling machine and other processing equipment.

Process Type: Injection Mold

Surface treatment: mirror, etching, sandblasting, electroplating, painting, etc.

Heating Method: Electric Heating/Oil Temperature Heating/Steam Heating

Scope of application: daily necessities, automobiles, medical treatment, electronics, household appliances.

[Product Requirements]

The product will not appear warping, flying edge, shrinkage, injection hole trace and other defects that affect the visual effect.

[Mould Maintenance]

Mould maintenance: Mould maintenance is more important than mould maintenance. The more times the mould is maintained, the shorter its service life; and the better the mould is maintained, the longer its service life will be.

Mould maintenance mainly consists of three points:

1. Daily maintenance: all kinds of moving parts such as thimble, row position, guide pillar, guide bush refueling, mould surface cleaning, water dredging, which is to be maintained every day during the production of the mould;

2. Regular maintenance: Regular maintenance includes cleaning of exhaust groove besides routine maintenance, adding exhaust gas to trapped gas burning black position, damage and wear parts correction, etc.

3. Appearance Maintenance: Paint on the outer side of the embryo to avoid rusting. When lowering the mould, anti-rust oil should be applied on the fixed mould, and the mould should be kept closed tightly to prevent dust from entering the cavity.