Automatic Rope Wire Cable Seal Cutting Annealing Machine

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 10 pcs per month |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Shenzhen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

Product Detail

| Model No.: | WT-500 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Raw Material: | Steel Bar |

| Power: | Hydraulic |

| Machine Type: | Others |

| Automation: | Automatic |

| Extra Services: | Cut To Length |

| Material / Metal Processed: | Stainless Steel |

| Brand Name: | Fortune Sky |

| Machine dimension: | 80x80x150cm |

| Wire Diameter: | 1-5mm |

| Cutting Length: | 10cm to 30m |

| Production Capacity: | 10 pcs per month |

| Packing: | wooden box |

| Delivery Date: | 15 working days |

Product Description

Once upon a time, there was a factory owner named Tom who ran a production and processing company. Tom noticed a problem in his manufacturing process - the production of various lead-sealed wire ropes, wire rope locks, sealing wire ropes, and other batches of wire ropes required manual handling, which led to inconsistent quality and labor difficulties for his workers. Tom was determined to find a solution to simplify the processing procedures, reduce costs, and increase production capacity.

One day, Tom discovered a fully automatic rope wire cable seal cutting annealing machine. This machine was specifically designed to address the challenges faced by the production and processing industries. It was capable of fusing and grinding wire ropes, resolving the unstable quality issues associated with manual processing. Tom was intrigued by the potential of this equipment to save human labor and streamline operations.

The machine's features were impressive. It had a high-precision touch-type computer control system, which made it easy to set and adjust the fuse conditions. This ensured consistent and high-quality fusing of wire ropes. Tom realized that with this machine, he could achieve better production efficiency and eliminate the need for labor-intensive manual processes.

Excited by the possibilities, Tom immediately introduced the fully automatic rope wire cable seal cutting annealing machine into his factory. The impact was significant. The machine not only saved valuable labor resources, but it also simplified the processing procedures, reducing production costs in the long run. Moreover, with easy-to-use controls and reliable performance, the machine improved overall production capacity.

Soon, word of Tom's success spread, and other industries took notice. The fully automatic rope wire cable seal cutting annealing machine became widely used in various sectors such as medical equipment, auto parts, construction safety, office furniture, bicycles, sports equipment, and locks. Its versatility and ability to improve production efficiency made it an indispensable tool for many manufacturers.

Thanks to the fully automatic rope wire cable seal cutting annealing machine, Tom's factory flourished. He no longer had to worry about unstable wire rope quality or labor difficulties. With just a single machine managed by a skilled operator, production soared, and Tom's business grew by leaps and bounds.

And so, the fully automatic rope wire cable seal cutting annealing machine became a game-changer in the production and processing industry. Its innovative design and exceptional performance reshaped manufacturing processes, enabling businesses like Tom's to thrive in a competitive market.

Details of Machine

Special design of feeding wheel,more precise feeding size,more wire diameter specifications to adapt to avoid troublesome replacement work.

Stepper motor drive,efficient and accurate

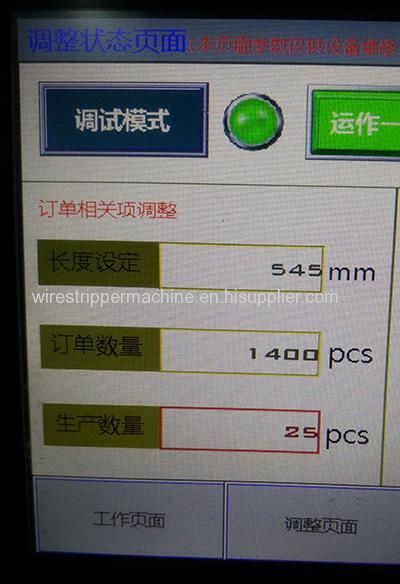

The length setting only needs to input numbers.

Special chuck,smoother feeding,no sticking line,deviation phenomenon,tighter holding,fast heating,small wear rate of chuck

High power tightening drive motor,high precision synchronous belt drive

Tighten the speed and segment to ensure that the tip is beautiful and not scattered.

Adjustable head and length adjustment device,easy to adjust,simple and easy to operate.

Intelligent control,human-machine interface, microcomputer control

Fault detection,shortage,product stacking can detect alarm.

Ultra high power transformer

High power current controlled thyristor

DC controlled high power dual power supply

Main technical requirements and instructions

1. The wire rope of the wire rope having a diameter of 1-5 mm which can be completed by the fuse machine.The equipment adopts the stepper motor (8mm above adopt servo motor) to ensure the fuse length is accurate,the melting section is conical,the largest circular surface diameter of the conical surface is smaller than the diameter of the steel wire,and the melting section is not scattered.it is quick and convenient to change the fuse length by using the touch screen.

2. Size requirements for wire rope and fuse:

A.The fuse material is a wire rope with no cotton inside.

B.The wire rope diameter is required to be 1-5mm (requires replacement of the clamping die).

C.The maximum wire diameter that can be blown is 5mm and the length is not limited. (If larger diameter material processing is required, it needs to be customized separately).

D.The fuse length size can be touched on the touch screen by the "Total Length"display box,pop-up digital setting keyboard and the length can be set arbitrarily.

E.Wire break accuracy is approximately +/-0.060 inch- +/-0.500 inch.

3. Feature:

Voltage:380V+220V

Air Source:0.4MPa

Size:80x80x150cm

Wire Diameter:1-5mm

Cutting Length:10cm To 30m

Lanuage:English/Chinese

Part of the wire diameters wire ropes blowing effect

1.8mm

2.0mm

2.5mm