Reinforced High Precision Extruded Polyamide Profiles for Solar Panels

| Min. Order: | 20000 Meter |

|---|---|

| Trade Term: | FOB,CIF,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 5,000,000 Meters/Month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Nanjing, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service, Other |

Product Detail

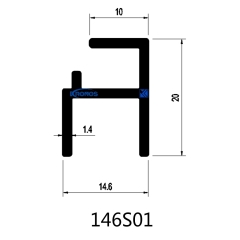

| Model No.: | 146S01 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | Kronos |

| Product Name: | Polyamide Profiles for Solar Panels |

| Material: | PA66 GF25 |

| Color: | Black |

| Width: | 14.6mm |

| Density: | 1.30±0.05 g/cm3 |

| Standard Length: | 6 Meters/Piece |

| Certificate: | IATF 16949:2016 |

| Processing: | High Precision Polyamide Extrusion |

| Standard Carried: | European Standard EN 14024:2004 & GB/T 23615.1-2017 |

| Application: | Replacement of Aluminum Solar Panels Parts |

| Production Capacity: | 5,000,000 Meters/Month |

| Packing: | Customized |

| Delivery Date: | 20 Days |

Product Description

Overview

Photovoltaic solar panels absorb sunlight as a source of energy to generate electricity. A photovoltaic (PV) module is a packaged, connected assembly of typically 6x10 photovoltaic solar cells. Photovoltaic modules constitute the photovoltaic array of a photovoltaic system that generates and supplies solar electricity in commercial and residential applications. The price of solar electrical power has continued to fall so that in many countries it has become cheaper than ordinary fossil fuel electricity from the electricity grid since 2012, a phenomenon known as grid parity.

Most of today's solar panels components and accessories are still made of heavy aluminum which is not a good option. Using extruded polyamide profiles to replace the aluminum parts for solar panles is a wise choice and the future. Using lightweight plastic profiles instead of heavier metal components can also help solar panel manufacturers to gain a competitive edge.

Kronos Precision Extrusion is a Singapore-Germany joint venture which specializes in developing and manufacturing Thermal Insulating Polyamide Profiles with Astonishing High Precision Thermoplastic Extrusion process and techniques. We offer a range of standard and custom-made extruded profiles from Virgin Polyamide 66 (PA66 or Nylon 66) and other materials for aluminum windows, doors, facades, solar panels, automotive sunroof slide rails, and various engineering applications.

Made from hard-wearing Polyamide with Fiberglass Reinforcement, Kronos's polyamide profiless feature excellent corrosion resistantance and durability with a material that is about 50% lighter than the traditional aluminum. Thanks to our high-end extrusion methods, expertise, and technical know-how, which guarantees the production of extreme smooth surfaces and exact contours despite the fiberglass reinforcement. Free from burrs, Kronos's Fully-Customizable polyamide profiles for solar panels can be quickly integrated and installed for optimum performance and the highest levels of customer satisfaction.

Product Name: Fiberglass Reinforced Polyamide Profiles for Solar Panels

Manufacturer: Kronos Precision Extrusion

Kronos Extrusion Model No.: 146S01

Main Material: Virgin Polyamide PA66 (or Polyamde 6)+ Pure Glass Fiber, or as per customers' requirements

Processing: High Precision polyamide extrusion

Standard Length: 6 meters/piece or customized

Shore Hardness: 80

Polyamide Profiles Color: Black

Standards Carried: European Standard EN 14024:2004 & Chinese GB/T 23615.1-2017

Kronos Extrusion Certification: IATF 16949:2016

Applications: Solar PV Ground Mounting Rack, Solar Panel Bracket, Solar Ground Mount Rail etc

Benefits of High-Performance Polyamide Profiles for Solar Panels

Lightweight - 50% lighter than aluminum parts

Extremely Smooth Surface

Long-Lasting, High Precision with Excellent Reliability

Hard-Wearing - Virgin Polyamide 66 or PA6 with Fiberglass Reinforcement guarantees the strength

Stable and Thermally Resistant

Corrosion Resistant

Electrically Insulated

Fully-Customizable - Ease of Integration and Installation for the Solar Panel manufacturers

Our extensive experience in high precision plastic extrusion & fabrications allows us to work closely with your design team to meet your most critical needs. The Kronos engineering team delivers prototypes quickly once your design is finalized. Kronos's experts' highly-professional expertise and technical know-how in new product development of thermoplastic extrusions, which ensures us to be flexible and quickly adaptable to meet your specific needs.

Our system design and manufacturing capabilities span a broad range of products and thermoplastic polymers which makes us the perfect partner for all of your standard and tailor-made high precision thermoplastic profiles extrusion needs.

Exchange of Know - Customers and the Kronos Precision Extrusion Team