20mm Thermal Insulation Polyamide Strips for Aluminium Doors & Windows

| Min. Order: | 20000 Meter |

|---|---|

| Trade Term: | FOB,CIF,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 5,000,000 Meters/Month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Nanjing, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service, Other |

Product Detail

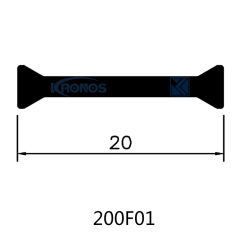

| Model No.: | 200F01 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | Kronos |

| Product Name: | Thermal Insulation Polyamide Profiles, Polyamide Strips |

| Material: | PA66 GF25 |

| Color: | Black |

| Width: | 20mm |

| Density: | 1.30±0.05 g/cm3 |

| Standard Length: | 6 Meters/Piece |

| Certificate: | IATF 16949:2016 |

| Processing: | High Precision Polyamide Extrusion |

| Standard Carried: | European Standard EN 14024:2004 & GB/T 23615.1-2017 |

| Application: | Aluminum Profiles, Thermal Break Aluminum Windows and Doors |

| Production Capacity: | 5,000,000 Meters/Month |

| Packing: | Customized |

| Delivery Date: | 20 Days |

Product Description

Overview

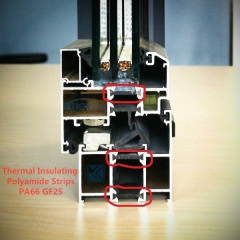

Without effective Insulation, also referred to as Thermal Break, Thermal Strut or Thermal Barrier, ordinary aluminum windows, doors, and facades transfer heat and cold, which results in a huge loss of valued thermal energy. This is where Kronos's Thermal Insulating Polyamide Profiles come into play.

The role of the thermal break is twofold – it must be a very poor heat conductor, blocking heat from moving from inside the house to outside and vice versa. Its another job is structural as it holds the two metal profiles together. The result is a frame that stands shoulder to shoulder, in energy efficiency terms, with frames made in wood. However there is another, lesser known advantage of a Nylon (Polyamide) thermal break – that of sound absorption. Just like metal conducts heat it also conducts sound and just like the insulating material blocks heat from passing it also dampens sound vibrations very effectively making for better sound insulation from outside noise.

Kronos Precision Extrusion is a Singapore-Germany joint venture that leads the way in developing and manufacturing Thermal Insulating Polyamide Profiles with Astonishing High Precision Thermoplastic Extrusion process and techniques. We offer a range of standard and custom-made extruded profiles from Virgin Polyamide 66/Polyamide 6(PA66/PA6 or Nylon 66/Nylon 6) and other materials for constructional, commercial, institutional, automotive, and engineering applications.

The state-of-the-art insulation techniques used by Kronos Precision Extrusion, connects the outer chamber and the inner chamber through Pure Fiberglass (25%) Reinforced Polyamide Strips. These strips provide a thermal break and come in various widths and shapes. Wide and Intricate polyamide extrusions that challenge today's extrusion capabilities are the jobs that Kronos thrives upon.

If you buy Thermal Break Polyamide Profiles from Kronos Precision Extrusion, you'll know just how accurate they are and how precisely they fit together with the aluminum frames.

Technical Details

Product Name: Thermal Insulation Polyamide Profiles - Thermal Break Polyamide Strips- Thermal Barrier Polyamide Strips, Thermal Struts

Kronos Model No.: 200F01

Material: Nylon 66 + Glass Fibre - Polyamide PA66 GF25

Processing: High Precision Polyamide Extrusion

Width: 20mm

Density: 1.30 ± 0.05 g/cm³

Shore Hardness: 80

Polyamide Profile Color: Black

Standard Length: 6 meters/piece

Certification: IATF 16949:2016

Standards: European Standard EN 14024:2004 & GB/T 23615.1-2017

Applications: Thermally Broken Windows and Doors, Passive Windows, Energy-Efficient Buildings, Passive House, Sustainable Buildings etc.

Kronos Precision Extrusion develops, designs, and produces a wide range of Thermal Break Polyamide Profiles for various applications.

Kronos Precision Extrusion implements a solid and comprehensive quality control during the whole process.

National Non-Ferrous Metal Inspection & Industrial Standards Institute Leaders Visiting Kronos Precision Extrusion