importance of magnetic separation separator

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10-100t/h |

| Place of Origin: | Shanghai |

Company Profile

| Location: | Shanghai, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | CTB |

|---|---|

| Means of Transport: | Ocean |

| Type: | Separator |

| Application: | Ore |

| Brand Name: | SHUOSEN |

| Application: | Iron ore processing |

| Production Capacity: | 10-100t/h |

| Packing: | standard export packing |

| Delivery Date: | in 15 working days |

Product Description

Magnetic separation is a method to separate useful minerals from minerals according to their magnetism.

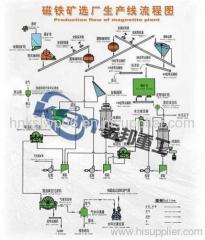

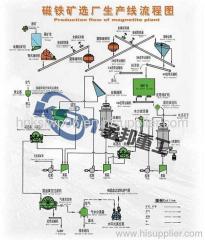

Magnetic separation is one of the most widely used and mature technologies, which is mainly used for the separation of magnetic minerals. Magnetic separation machine plays an important role in this process.The mined ore is first broken by a jaw crusher, which is broken to a reasonable fineness and then uniformly sent to a ball mill by a hoist and a ore feeder, which crushes and grinds the ore.After the ball mill grinding ore fine material into the next process: grading.The spiral classifier cleans and classifies the ore mixture by the principle that the proportion of solid particles is different and the rate of precipitation in the liquid is different.When the cleaned and graded mineral mixture passes through the magnetic separator, the magnetic substances in the mixture are separated by magnetic force and mechanical force due to the different specific magnetization coefficients of various minerals.Note: this process is designed according to the standard process and can be optimized according to the annual output and requirements of customers.

Strong magnetic minerals: magnetite, pyrrhotite, etc.Medium magnetic minerals: semi - pseudomorphic hematite and some ilmenite, chromite, etc.Weak magnetic minerals: hematite, limonite, carbonatite, ferromanganese, pyrolusite, rutile;Non-magnetic minerals: quartz, feldspar, fluorite, etc.

The above minerals can only be further smelting or other USES after magnetic separation processing, according to the different magnetization coefficient of various minerals, magnetic separation machine with different magnetic field intensity is needed for magnetic separation.

Magnetic separation equipment generally speaking is the magnetic separator.

Application of Magnetic separator

Magnetic separator is a continuous automatic iron removal magnetic separation equipment from dry power. It s inner adopts unique magnetic circuit design, it make the high-performance permanent magnet king NdFeB materials as the magnetic source, strong magnetic field, big attraction force, high iron removal rate, has the advantages of three maintenance, energy conservation, safe and reliable operation, feed quantity can be adjusted, used for different particles requirements. The magnetic separator is widely used in abrasives, refractories, nonmetal beneficiation, carbon black, grain, feed, chemicals and other industries.

If you want to know more about our equipments details,please contact us

Shanghai Shuosen Mining Machine Co.,Ltd