Ore flotation separation equipments

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10-100t/h |

| Place of Origin: | Shanghai |

Company Profile

| Location: | Shanghai, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | SF |

|---|---|

| Means of Transport: | Ocean |

| Type: | Separator |

| Application: | Ore |

| Brand Name: | SHUOSEN |

| Application: | Gold ore processing |

| Production Capacity: | 10-100t/h |

| Packing: | standard export packing |

| Delivery Date: | in 15 working days |

Product Description

Flotation separation refers to the use of a large number of bubbles can produce surfactant - foaming agent.When air enters the water or is caused by water agitation, the hydrophobic end of the surfactant is oriented towards the air bubbles in the gas-liquid boundary, and the hydrophilic end is still in the solution, forming bubbles.Another surfactant that ACTS as a collector (usually a cationic surfactant, also including aliphatic amine) is adsorbed on the surface of a solid mineral powder.This kind of adsorption has certain selectivity with different mineral properties. The basic principle is to make use of lattice defects on the crystal surface and insert part of the hydrophobic end outward into the bubble, so that the bubble may take away the specified mineral powder in the flotation process to achieve the purpose of ore dressing.

The flotation method is widely used for the separation of metallic minerals, non-metallic minerals, chemical raw materials minerals and so on.Another important use of flotation is to reduce ash content in fine coal and to remove fine pyrite from coal.

Flotation separation according to the separation of valuable components can be divided into positive flotation and reverse flotation, the useless mineral (gangue mineral) surface in the slurry as tailings discharge method is called positive flotation;Conversely, it is called reverse flotation.The commonly used flotation agents in flotation are collector, foaming agent, inhibitor, activator, pH regulator, dispersant, flocculant and so on.Common flotation machines are mechanical agitation, inflatable, pneumatic mechanical agitation and so on.

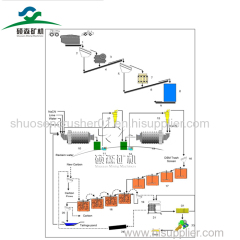

Flotation process equipments

Flotation process by jaw crusher, ball mill, classifier, magnetic separator, flotation machine, concentrator and dryer and other main equipment, with ore feeder, hoist, conveyor, vibrating screen can form a complete ore processing line.The production line has the advantages of high efficiency, low energy, high processing capacity, economical and reasonable.

If you want to know more about our equipments details,please contact us