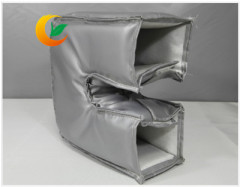

Customized Injection machine/Tank/Equipment Insulation Jacket/cover Supplied by Factory Directly

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 10000/pcs month |

| Place of Origin: | Hunan |

Company Profile

| Location: | Changsha, Hunan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Distributor/Wholesaler, Service |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Material: | Glass |

| Brand Name: | Venice |

| Apparent Density: | 50-200kg/m3 |

| Heat Conductivity: | 0.035 W/M |

| Highest Working Temperature: | 1000-280℃ |

| Place of Origin: | China |

| materials: | fiberglass |

| Brand Name: | venice |

| Density: | 50-200kg/m3 |

| Thickness: | 50-150mm |

| Production Capacity: | 10000/pcs month |

| Packing: | carton |

| Delivery Date: | 3-7days |

Product Description

Why Reusable & Removable Thermal Insulation Cover?

>Keep Heat/Cold In and Out

>Easy to Remove and Re-install

>Heat Conservation, Saving Energy Costs, Increase energy efficiency

>Fire, Freeze & Personnel Protection

>Protection of personnel or manufacturing environment system

>Temperature control,Reduced Room Temperature

>Sound Reduction

The Insulation Jacket is custom designed to significantly reduce heat loss and surface temperature for Plastics Extrusion, Injection Molding, and Blow Molding. The reduction in heat loss can save energy, thereby saving process electricity and air conditioning electricity. In addition to saving energy, the reduced heat loss will improve the surrounding work environment , thus increasing overall productivity.

All insulation covers are custom designed and manufactured ,to meet the requirements of your application.

Product Name | Customized reusable fiberglass thermal cover removable insulation jacket |

Material | Fiberglass, Ceramic Fiber , High Temperature Fabric |

Color | silver or customized color |

Fire Rating/ Inflaming Retarding | A Grade, GB8624-2006, German standard DIN4102 A1 |

Feature | Fireproof, Waterproof, Heat Insulated, Anti-corrosion, Long life |

Temperature Range | -198℃-1300℃ |

Moisture absorption rate: | <5% |

Thermal Conductivity | 0.025 W/M•K- 0.045 W/M•K±0.005 (Normal temperature) |

Density | 110-220Kg/m3 |

Thickness | 10-200mm |

Factory Certificate | ISO9001, ISO14001, OHSAS18001, ROHS |

Applications

Where can it be applied?

Steam & Gas Turbine Insulation Covers

Heat Exchanger Insulation Covers

Furnace Tube Insulation Covers

Vessel & Reactor Insulation Covers

Pump & Compressor Insulation Covers

Exhaust Bellow, Turbo Charger and Manifold Insulation Cover

Pipe Insulation Covers

Valve & Actuator Insulation Covers

Tee, Elbow, Reducer and Other Fittings Insulation Covers

Plastic Extruder Barrel Insulation Covers

Insulation Covers for Customized Equipment

Advantages of Insulation Cover

•Long life, more than 3 years.

• Energy Saving. Reduce heat loss by 20%-40%,

•Surface temperature can be lowered to 40℃, is safe for touching by hands and operation

•Customized design is supported to 100% fit your application.

•Easy installation

•Water and oil proof, multi-layer protection, anti-corrosion, easy to clean, easy to bend, pollution free and neat out looking.

•Dimension, cut/hole sizes and positions are required for quotation. Drawings and pictures are preferred

Product Details

1. Inner Layer

1000℃-1200℃ high temperature insulated silicone fabric

or high-SI aluminum fabric.

2. Insulating layer(Middle Layer)

insulating layer is ceramicfiber or glass fiber,

The standard thickness is about 25 to 30 mm, temperature resistance more than 1000℃.

3. Outer Layer( Protection Layer)

the protection layer is ceramic fiber with high temperature resistance paint coat, or Aluminum Foil ,Fiberglass Cloth,

4. Accessories

Velcro, grommets, anchor pins, loops, zippers are all available in different styles and shapes, for easy installation and fitting tight purpose.