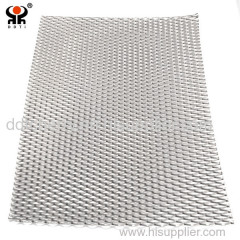

Titanium Mesh Sheet Heat Corrosion Resistance TA2

10.0 USD

| Min. Order: | 10 Kilogram |

|---|---|

| Payment Terms: | Paypal, L/C, T/T, WU |

| Supply Ability: | 100kg/month |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 05 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | DDT |

| material: | TA1 TA2 |

| thickness: | 0.5-2mm |

| color: | titanium natural color |

| application: | Medical filtration,Chemical filter, Mechanical filter |

| shape: | mesh sheet |

| coating thickness: | 0.5-5um |

| Hole Type: | diamond |

| Production Capacity: | 100kg/month |

| Packing: | plastic bags outside,standard export wooden case as outsid |

| Delivery Date: | 10-15days |

Product Description

1.Product introduction

Titanium mesh is mainly used for screening and alkali environmental conditions or gas, liquid filtration and other media separation. There are three methods of plain weave, twill weave, and dense weave. Due to the difficulty in drawing titanium wire, the most delicate titanium wire drawn in China can achieve 0.05mm, the elongation of titanium wire is low, the strength is large, the elasticity is large, and the flexibility is low. This greatly limits the production of high mesh titanium mesh. The size of the titanium mesh is 1 mesh - 400 mesh.

2. Product Classification

Plain titanium mesh

It is the most common weaving method, and its main feature is the same density of warp and weft wire diameters.

Titanium dense mesh

Plain weave pure titanium dense mesh, twill weave pure titanium dense mesh performance: with stable filtration performance, fine and so on. Uses: used in aerospace, petroleum, chemical and other industries.

3. product specifications

Number of mesh: 0.2 mesh - 400 mesh

Thickness: 0.5-2 mm, width: 100-300 mm, coating thickness: 0.5-5 um.

4. Material

TA1, TA2, GR2, GR3, titanium alloy, etc.

Material surface: 1. Black (the surface contains graphite emulsion coating)

2. Bright (no graphite coating)

Standard value

| Reference standard for chemical composition | |||||||||

| Grade | Al | V | N≤ | C≤ | H≤ | Fe≤ | O≤ | Other elements (single) | Other elements (sum) |

| TA1 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | 0.1 | 0.40 | ||

| TA2 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | 0.1 | 0.40 | ||

| TC4 | 5.5-6.75 | 3.5-4.5 | 0.05 | 0.08 | 0.015 | 0.30 | 0.20 | 0.1 | 0.40 |

| Reference standard for mechanical properties | ||||

| Grade | The mechanical properties at room temperature are not less than | |||

| Tensile strength | Yield strength | Elongation | Section shrinkage rate | |

| TA1 | 240 MPa | 170 MPa | 25% | 30% |

| TA2 | 345 MPa | 275 MPa | 20% | 30% |

| TC4 | 895 MPa | 825 MPa | 10% | 20% |

5. factory show

6.other products