Press Brake Metal Bending Mold Tool

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 800 piece/month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Brand Name: | BOKAI |

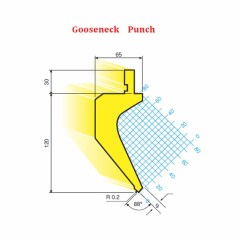

| Precision Level: | +-0.005mm |

| hardness: | 42-48HRC |

| material: | 42CrMo or customized |

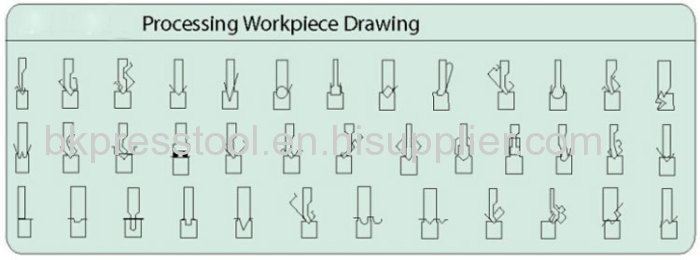

| application: | metal sheet bending |

| warranty: | 1 years |

| sharpness: | 18-30N |

| Production Capacity: | 800 piece/month |

| Packing: | wooden package |

| Delivery Date: | 15 days |

Product Description

Product Description

Forging mould molding method press brake dies or press brake tooling/mold making

Detailed Images

Company Information

Certification

FAQ

Q: What is the delivery time of your products?

A: It depends on the inventory availability. If items needed are in stock, the delivery time would be within 8 work days , but if not the delivery time would be around 20 working days .

Q: Can you manufacture special-shaped products?

A:Yes ,we can.We can produce both standard and special products We can make them according to your drawings and samples.

Q:Could you offer OEM and ODM service?

A:That is ok ,we have more than 10 years experience in OEM service

Q:Could you print our logo? and your payment terms?

A:Yes,we could laser your logos on products with free

payment terms :30%deposit,the balance before shipping.

Q: How do you guarantee your quality?

A: Material selection and hardness survey are critical for the sake of a quality knife and machine parts. We were formly engaged in forging, and had a good command of mechanics & property of different tool steels. Inspection on incoming materials is furthermore well taken care of. We partner with long-term raw providers physically near to us, which helps make us more competitive, and more importantly quality is ensured. We are serious and all our knife parts are always forged while those parts from most of our competitors are not. For hardness, our knives are uniformly heat treated and triple tempered. Specific hardness range is set up for any specific working condition, thus giving better wear resistance ability and longer working life.