plastic pvc lamination plywood/artificial marble sheet making machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10 sets/month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 80/156 |

|---|---|

| Means of Transport: | Ocean |

| Use: | Others |

| Plastic Type: | PVC |

| Shaft Design: | Double |

| Brand Name: | Kingshine |

| Power: | 75 kw |

| Plastic Processed: | PVC |

| Screw Design: | Conical twin screw |

| Usage: | Furniture, wall decoration |

| Output (kg/h): | 350 - 400 kg/h |

| Screw diameter: | 80/156mm |

| Dimension(L*W*H): | 30*5*5m |

| Warranty: | 1 year |

| Certification: | CE, ISO |

| Power: | 75 kw |

| Screw material: | SKD 11 |

| Production Capacity: | 10 sets/month |

| Packing: | Container packing |

| Delivery Date: | 45 days |

Product Description

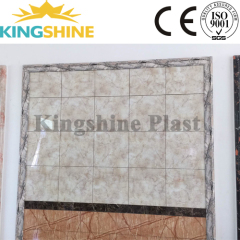

PVC Laminating/Marble Sheet Description

Applications:

As PVC Lamination/Marble Sheet is fireproof and waterproof, it is widely used in various luxury buildings such as hotels, restaurant, business buildings, bars, cafes and families. It belongs to high grade gorgeous decoration new material.

Advantages:

(1) Green environmental protection, does not contain formaldehyde, non-toxic harmless, non radioactive pollution, no pollution to the environment, belong to the green environmental protection products, can be recycled

(2) PVC super wear-resistant floor surface has a layer of special by high-tech processing transparent wear-resistant layer, with wear resistance strong, so PVC floor more and more popular in the hospital, in school, office buildings, shopping malls, supermarkets, transportation and other places

(3) Waterproof, moisture-proof, water is not deformation, non slip PVC material, strong anti-slippery, can eliminate the elderly, children's anxiety.

(4) Strong elastic shock, comfortable.

(5) Safety, insulation, flame retardant, corrosion resistance and alkali

(6) Novel color, a variety of colors available for selection, brilliant color, natural and vivid color, any spell group shape, highlight the individuality color.

(7) Installation convenience, convenient construction sawing, planing, nail, glue free paint.

(8) Long service life can reach more than 20 years.

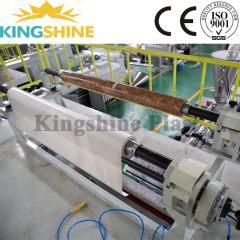

PVC Laminating/Marble Sheet Production Line Description

Production Line Processing

Raw material→ Mixer→ Extrusion→moulds→3-roller calendar→ hauling off→ cutting device→ stacking device→ checking up→ packing

With PVC sheet production line, PVC sheet is extruded out and shaped by three-roll calender. And the sheet surface is treated with lamination directly in line, which makes the sheet in many colors and texture. Kingshine PVC extruder adopts European standard. All part is controlled by Siemens PLC.

Parameters of PVC Laminating/Marble Sheet Production Line

Item | PVC Marble Laminate Sheet Production Line |

Screw diameter (mm) | 80/156 |

Screw Design | Conical twin screw |

Screw rotation speed (r/min) | 1-36.9 |

Effective length of screw (mm) | 1800 |

Main motor power (kw) | 75 |

Barrel heating power (kw) | 38 |

Capacity (kg/h) | 500 |

Central height (mm) | 1000 |

High-end Electrical Components

Kingshine adopts high-end electrical components such as Schneider electric control system, ABB inverter, Siemens PLC, Siemens motor.

The difference between PVC artificial marble sheet and real marble sheet

1. Real marble will suffer sulfur dioxide and the price is higher.In addition,the surface of artificial sheet could be changed according to customer's request freely.In addition,it is very important that the intallation is very easier and save a lot of labor cost.

2. PVC is economic and evironment friendly.It will take more market share gradually.

3. The lamination is achieved online and don't need any glue or other laminator.After producing this board,if you use UV machine,it would make the board much harder and brighter.

Certification

Our Company

Kingshine is one of the most professional plastic machinery manufacturing enterprises in China. The main production is PVC extrusion machinery:

1. SPC/LVT Flooring Production Line

2. PVC/WPC Door Board/Frame Production Line

3. PVC/WPC Foam Board Production Line

4. PVC Laminating/Marble Sheet Production Line

5. Mixer/Crusher/Miller

Kingshine pays attention to technological innovation, actively introduce advanced foreign technology, and constantly develop new products.

Our Service

1. Pre-sale service:

To provide information, market research and forecasting, provide consultancy, offers a variety of convenience and market service and so on.

Pre-sale service's main purpose is to assist the clients prepare the project planning and system requirements analysis, enable our products to maximize meet customer needs, but also to maximize customer investment play the comprehensive economic benefits.

2. After-sale service

1 Installation overseas

2 Provide all kinds of product formula, technology and chemical material manufacturer information

3 According to the customer's requirements, provide technical guidance

4 Technical training for employees of customers

5 Responsible for maintenance service, door to door service if necessary.

Contact Way