WPC PVC door panel extrusion machine line

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 9.6ton/24hr |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | SJSZ92/188 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | KINGSHINE |

| Machine name: | WPC PVC DOOR PANEL EXTRUSION LINE |

| Frequency converter: | ABB brand |

| Motor power: | 110KW |

| Hour capacity: | 400-600KG/H |

| Contactor: | Schneider |

| Width: | 800-900mm |

| Thickness: | 35,40,45mm |

| Machine size: | 40*5*5 |

| Warranty time: | 12 month |

| Control ways: | Simens PLC touch screen |

| Production Capacity: | 9.6ton/24hr |

| Packing: | standard sea package |

| Delivery Date: | 60 working days |

Product Description

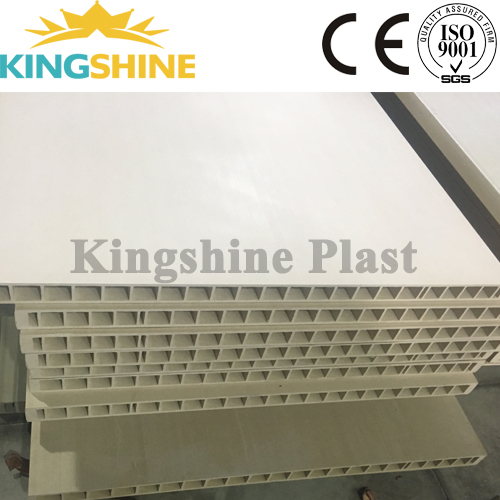

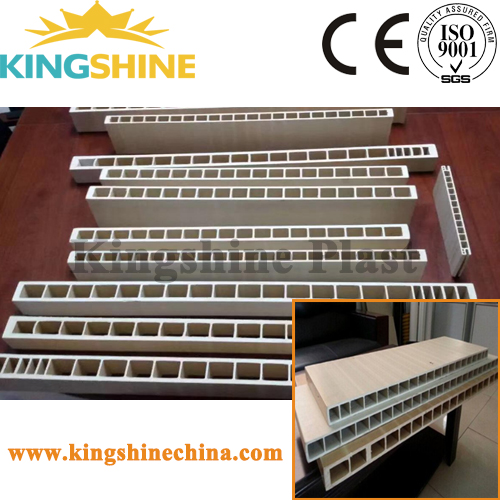

Description of PVC/WPC Door Board

Usage | Door Panel |

Width | 800-900 mm |

Thickness | 35-45 mm |

Wall Thickness | 5-7.5mm |

Foaming Ratio | 0.9 t/m3 |

Weight | 11.5-15 kg/m |

Advantages of PVC/WPC Door Board

• Fireproof

• Waterproof

• Formaldehyde Free

• Insect prevention

• Cost-effective

Description of PVC/WPC Door Board Production Line

Production Process of Door Board

Screw Loader for Mixer—High Speed Mixing Unit—Screw Loader for Extruder—Conical twin screw extruder—Mold—Vacuum calibration machine—Traction Machine—Cutting Machine—Stacking Table

| NO | Machine Name | Quantity |

| 1 | Screw Loader for Mixer | 1 |

| 2 | SRL-Z serious High Speed Mixing Unit | 1 |

| 3 | Screw Loader for Extruder | 1 |

| 4 | SJSZ serious Conical Twin Screw Extruder | 1 |

| 5 | Mold head+Calibration forming mold | 1 |

| 6 | Vacuum Calibration Machine | 1 |

| 7 | Traction Machine | 1 |

| 8 | Cutting Machine | 1 |

| 9 | Stacking Table | 1 |

Features of the Machine

1)Extruder screw and barrel from Zhoushan,with vacuum degassing system, can get rid of the waste gas from the raw material which can ensure good quality of final granules.

2) Gearbox: From Jiangyin gearbox company,very famous brand in China,with nice outline, stable running, low noise and long service time.

3) Heating system: adopting cast aluminum heaters with stainless steel plate covers, wind fan cooling system, ensuring good features of cooling and heating, precision temperature controlling.

4) Driving system: adopting Siemens motor, using ABB inverter which provide stable torque output and various speed.

5) Vacuum calibrating and cooling Table: the tabley is made by #304 stainless steel, good strength and performance,long life time.

6) Traction machines:Rubber block traction belt,traction speed is adjustable by ABB frequency inverter.

7) Cutting machine: saw blade cutting,low noise,quick cutting performance,with dust collection device.

High-end Electrical Components

Kingshine adopts high-end electrical components such as Schneider electric control system, ABB inverter, Siemens PLC, Siemens motor.

Certification

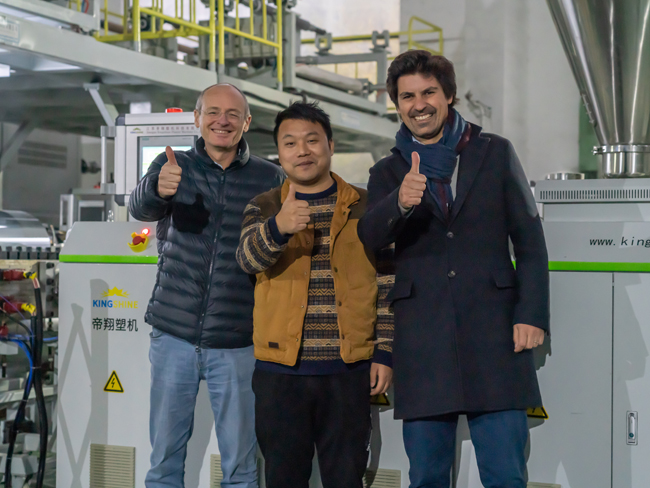

Our Company

Kingshine is one of the most professional plastic machinery manufacturing enterprises in China. The main production is PVC extrusion machinery:

1. SPC/LVT Flooring Production Line

2. PVC/WPC Door Board/Frame Production Line

3. PVC/WPC Foam Board Production Line

4. PVC Laminating/Marble Sheet Production Line

5. Mixer/Crusher/Miller

Kingshine pays attention to technological innovation, actively introduce advanced foreign technology, and constantly develop new products.

Our Service

1. Pre-sale service:

To provide information, market research and forecasting, provide consultancy, offers a variety of convenience and market service and so on.

Pre-sale service's main purpose is to assist the clients prepare the project planning and system requirements analysis, enable our products to maximize meet customer needs, but also to maximize customer investment play the comprehensive economic benefits.

2. After-service

1 Installation overseas

2 Provide all kinds of product formula, technology and chemical material manufacturer information

3 According to the customer's requirements, provide technical guidance

4 Technical training for employees of customers

5 Responsible for maintenance service, door to door service if necessary.