SPC Stone Plastic Floor Extrusion Line Supplier

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 20 |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | SZ110 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | KINGSHINE |

| Plastic type: | PVC |

| Product width: | 980/1250mm |

| Product thickness: | 2~8mm |

| Capacity: | 15~30~45ton/24hrs |

| Motor: | 110~200kw |

| Export port: | Shanghai |

| Production Capacity: | 20 |

| Packing: | wooden case or FCL |

| Delivery Date: | 45days |

Product Description

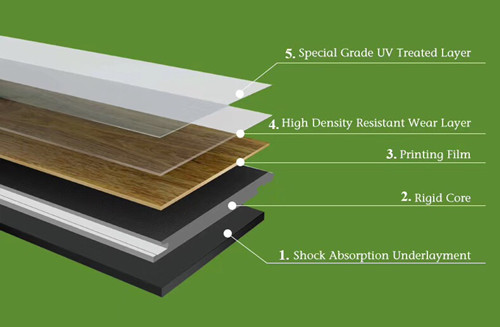

SPC Floor Introduction:

SPC (stone plastic composite) stone plastic floor is a new environmentally-friendly floor developed based on high technology. It contains no formaldehyde which makes it

mildew-proof, moisture-proof, fireproof, insect-proof, dust mite-proof and easy to install.

High environmental protection, no pollution, and can be recycled.SPC is flame retardant, with high fire resistance reaches the B1 level. It self-extinguishes in case of fire as well as not producing any toxic gas; No cracking, no expansion, no deformation, no maintenance and easy to clean.Good sound absorption and energy conservation, saving up to 30% of the indoor energy. In comparison with other floors, the SPC floor has less investment cost, labor, and keeps the environment clean.Good sound absorption and energy conservation. Additionally, save up to 30% of indoor energy; Compared with other floors, the SPC floor has less investment cost, labor, and keeps the environment clean.

SPC floor is extruded by extruder and T-die , with four-roll or five-roller calender, respectively, PVC wear layer, PVC color film and PVC substrate, one-time heating paste, embossed products , The process is simple, close by heat to complete, do not need glue.

SPC Floor Extrusion Machine Options:

| SPC Flooring Machine | Conical twin screw extruder | parallel twin screw extruder | |||

| Model | 92/188 | 110/220 | 115 | 136 | 160 |

| Thickness(mm) | 2-8 | ||||

| Width(mm) | 1050,1350 | ||||

| Extruder motor(kw) | 110 | 200 | 90 | 160/200 | 250 |

| Output | 15ton/24h | 30ton/24h | 18-22ton/24h | 40-45ton/24h | 60-65ton/24h |

What machines required for the SPC floor plank?

Step 1: Material mixing and recycling

Hot-cold mixing machine, crusher and milling machine.

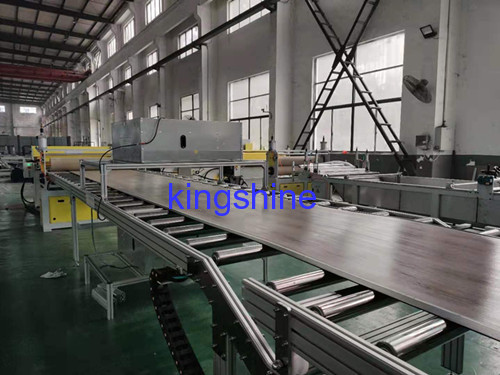

Step 2: Extrusion (laminting&embossing):

SPC floor extrusion line

Step 3:UV Coating

UV coating machine

Step 4:Cutting& Slotting

Cutting and slotting machine

Step 5: V shape groove UV coating (optional)

V-groove coating machine

Step 6: Underlayer laminating

Hot glue laminating machine

About Us

Jiangsu Kingshine Plast Machine Co.,Ltd is one of the most professional plastic machinery manufacturing enterprises in China. The main production is SPC/LVT floor extrusion machine, PVC sheet extrusion machine, PVC/WPC door board/frame extrusion machine, PVC laminating/marble sheet extrusion machine, ect. Kingshine pay attention to technological innovation, actively introduce advanced foreign technology, and constantly develop new products.

Kingshine supply SPC floor production line not only machine but also formula and technology, help customer start the project with professional servic.

Our advantage:

European Standard Machines

On-line EIR technology which is our patent technology.

The most advanced parallel 136 stable using in market

Special Five-roller calender (Patent)

We participated the 5 years SPC floor development. We are always on the road of R & D and keep leading position.

We have large customer base in China, from which we get lasted news about SPC floor, we get demand, find problems, improve problems, test and verify new technology, to keep our machine stable running, meet customer's demand, and keep our machine the most advanced.

Our Service

Pre-sale service

-To provide information and market research.

-To provide consultation,to provide many kinds of conveniences and market service,etc.

-To help customers make the project planning and system requirements analysis.

-Take our products maximum to meet clients' requirements.

-To play the greatest overall economic benefits of customers' investment.

After-sale service

-To install products and test products freely for customers.

-To provide the formulas and technologies of relevant products and the information of chemical materials manufactories.

-To direct technology aspect of relevant use according to customers' requirements.

-To provide technical training for clients' employees.

-To be responsible for maintenance service, door-to-door service under the necessary circumstance.

Contact:

Joy Zhang

Int'l Sales Manager

Mobile/Whatsapp: +86 13405773767

Skype/Wechat: yizhang28