SPC Flooring Production Line (parallel twin srew)

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10 set/month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 136 |

|---|---|

| Means of Transport: | Ocean |

| Use: | Others |

| Plastic Type: | PVC |

| Shaft Design: | Double |

| Brand Name: | Kingshine Plast |

| Power: | 160 kw |

| Plastic Processed: | PVC |

| Output: | 40 t/24h |

| Dimension(L*W*H): | 50*5*7m |

| Power: | 160 kw |

| Application: | Sheet, Plates |

| Screw Material: | SKD 11 |

| Screw Design: | Parallel twin screw |

| Screw diameter: | 136 mm |

| Certification: | CE, ISO |

| Warranty: | 1 year |

| Production Capacity: | 10 set/month |

| Packing: | Container pack |

| Delivery Date: | 45 days |

Product Description

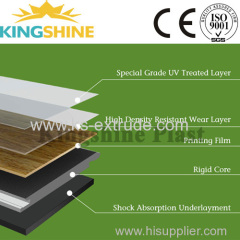

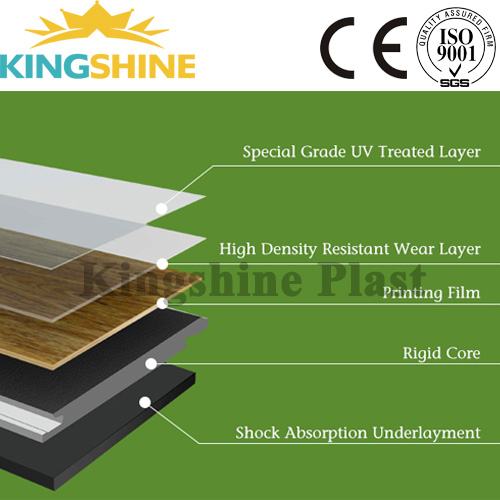

SPC Floor Description

SPC floor sheet is composed by pvc resin, calcium powder and other additives, to produce various design of spc floor sheet.

SPC flooring tile can be widely used in bedrooms, halls, kitchens and toilets; office buildings, libraries, museums, shopping malls, restaurants, factories, schools, hospitals and other ground pavement.

Advantages of SPC Flooring Production Line

(1) 100% waterproof, suitable for any indoor area in addition to the outdoor use;

(2) The high environmental protection, zero formaldehyde, food grade;

(3) The fire rating Bf1 level;Highest standard for floor, applicable to fire control occasions with higher requirements;

(4) High strength wear resistant;

(5) The moistureproof prevent slippery, moth-proofing anticorrosive antibacterial;

(6) The foot feels comfortable, sound-absorbing the effect is good.

(7) The installation is simple, maintenance is convenient;

(8) Response real wood texture, can be adjusted according to need different colors;

(9) WPC floor there are risks deformation at room temperature under 0 ℃;

(10) SPC floor is suitable for the cold (-20 ℃) to the extreme heat (60 ℃) use of interior space.

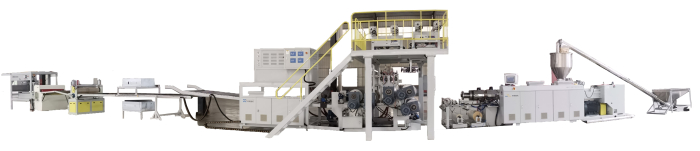

SPC Flooring Production Line Description

Jiangsu Kingshine Plast Machine Co., Ltd developed the EIR SPC Flooring Production Line(Parallel Extrude),which has the following advantages compared with the traditional conical twin screw SPC floor production line.

1.The output is large.

2.Low energy consumption,energy consumption per unit output is 70% of conical twin screw extrusion.

3.The screw has a long service life,which is twice the service life of the conical twin screw.

4.The company's special five-roller calender improves the peeling strength of SPC floor ,making the embossing more realistic.

5.The on line EIR technology,with high accuracy and automation.

High-end Electrical Components

Kingshine adopts high-end electrical components such as Schneider electric control system, ABB inverter, Siemens PLC, Siemens motor.

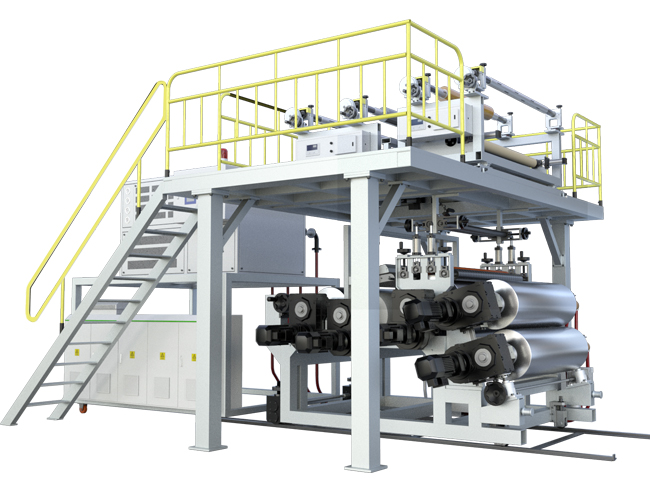

Five Roller Calander System

We use five roller calander system, and this is a special design that we invent. Contrast to the normal four roller type, the five-roll not only greatly improves the production efficiency, but also enables the color film and wear-resistant layer to be more closely bonded to the sheetand increase their peeling strength.

The first three roller is heated by oil, so the color film and wear layer is bonded to the sheet by hot press without glue.

The last two roller is cooled by water, so when the temperature change, the embossing design and embossing depth won't change.

The third roller is laminating roller, our roller have a bigger design, and its diameter is 600mm. Contrast to other 400mm normal one, our bigger size laminating roller can increase the bonding area between the color film and the wear-resistant layer and the sheet, so that they can be more closely adhered together, and increasetheir peel

The forth roller is a rubber roller, contrast to normal steel roller, rubber roller can increase the strength and depth of embossing and make the floor more realistic.

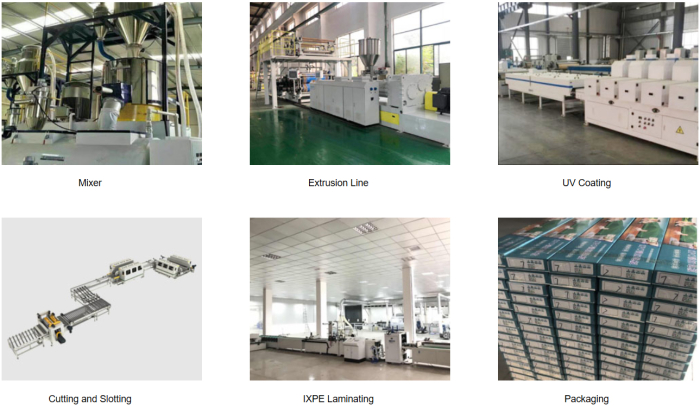

SPC Floor Production Process

Parameters of SPC Floor Machine

| Model | 115 | 136 | 160 |

| Thickness (mm) | 2-8 | 2-8 | 2-8 |

| Width (mm) | 1050, 1350 | 1050, 1350 | 1050, 1350 |

| Extruder Motor (kw) | 90 | 160 | 250 |

| Output | 18-22 t/24h | 40-45 t/24h | 60-65 t/24h |

Certification

Our Company

Kingshine is one of the most professional plastic machinery manufacturing enterprises in China. The main production is PVC extrusion machinery:

1. SPC/LVT Flooring Production Line

2. PVC/WPC Door Board/Frame Production Line

3. PVC/WPC Foam Board Production Line

4. PVC Laminating/Marble Sheet Production Line

5. Mixer/Crusher/Miller

Kingshine pays attention to technological innovation, actively introduce advanced foreign technology, and constantly develop new products.

Our Service

1. Pre-sale service:

To provide information, market research and forecasting, provide consultancy, offers a variety of convenience and market service and so on.

Pre-sale service's main purpose is to assist the clients prepare the project planning and system requirements analysis, enable our products to maximize meet customer needs, but also to maximize customer investment play the comprehensive economic benefits.

2. After-sale service

1 Installation overseas

2 Provide all kinds of product formula, technology and chemical material manufacturer information

3 According to the customer's requirements, provide technical guidance

4 Technical training for employees of customers

5 Responsible for maintenance service, door to door service if necessary.

Contact Way