PVC Marble Sheet Extruder Machinery

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20sets/month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 110/220 |

|---|---|

| Means of Transport: | Ocean, Land |

| Use: | Others |

| Plastic Type: | PVC |

| Shaft Design: | Double |

| Brand Name: | 110KW |

| Power: | 110KW |

| Capacity: | 1000-1350kg/hr |

| Advanced system: | PLC Control system |

| Type of Inverter: | ABB inverter |

| automactic Degree: | Automatic sheet collector |

| Fast delivery time: | Turnkey project |

| Voltage: | 380V/50hz |

| Product Thickness: | 3-25mm |

| Mechanical line speed: | 0.6-6m/min |

| Weight: | 18Tons |

| Daily Capacity: | 25-32T |

| Contactor: | Schneider |

| Production Capacity: | 20sets/month |

| Packing: | film or wood |

| Delivery Date: | 45days |

Product Description

PVC Marble Sheet Extruder Machinery

Laminated sheet has the water-proof,anticorrosion and

light quality effects.The product has marble pattern, granite

pattern imitation wood grain, rationale pattern, solid color

semipermeable heart and other patterns.

It has such characteristics as flame retardant, anti-corrosion, non-slip,

resistant to pressure, stable quality, low prices and simple construction,

compared with other flooring materials with better performance, better

decorative effect, is suitable for the movable plank house, factories,

shopping malls, home, office and other occasions.

Machinery Features

1.One construction worker can install thirty to forty square meters every day.

Imitation marble material can achieve seamless splicing, you can also choose

a 45-degree angle cut, V-groove and so on.

2.In addition,it is very important that the insallation is very easier and save

a lot of labor cost.

3.PVC is economic and environment friendly.It will take more market share

gradually.

Clear grains, no color difference, wear-resistant surface, hardness up to 3H-6H, B1 level flameproof, no radiation, the lowest outdoor aging up to 15 years,

the weight is 1/6 of the natural stone,with small impact on building load, can be

a large area of paving,and the price is only 1/10 of the natural stone.

Natural stone is generally wet on dry hanging,has high construction costs, but

the imitation marble construction which use structural adhesive or glass adhesive,

can be fast and firm.

The difference between pvc artificial marble sheet and real marble sheet:

Real marble will suffer sulfur dioxide and the price is higher.In addition,the surface

of artificial sheet could be changed according to customer's request freely

PVC is economic and environment friendly.It will take more market share gradually

Application

1. Building outdoor wall board, indoor decoration board, partition board in office and house.

2. Screen printing, flat solvent printing, engraving, billboard and exhibition display.

3. Chemical anti corrosion project, special cold project, environmental protection

4. Sanitarywares, kitchen cabinet, washroom cabinet.

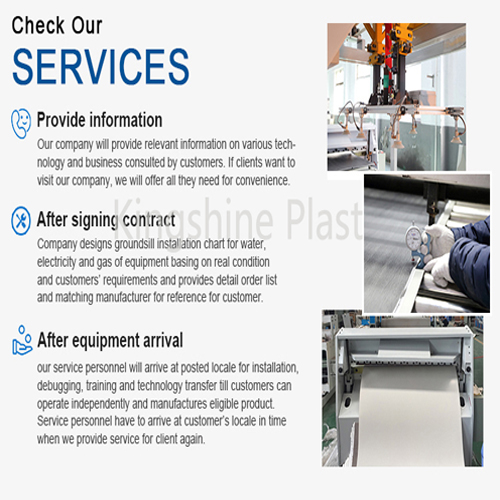

Service

Packing