PVC Door Panel Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20sets/month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 80/156 |

|---|---|

| Means of Transport: | Ocean, Land |

| Use: | Others |

| Plastic Type: | PVC |

| Shaft Design: | Double |

| Brand Name: | Kingshine |

| Power: | 75kw |

| Capacity: | 400 |

| Certification: | SGS,BV,CE |

| Inverter: | ABB |

| Contactor: | Schneider |

| Color: | Customer Choice |

| Thickness: | 1-8mm |

| Daily Capacity: | 12-18Tons |

| Production Capacity: | 20sets/month |

| Packing: | Plastic film or wood |

| Delivery Date: | 60days |

Product Description

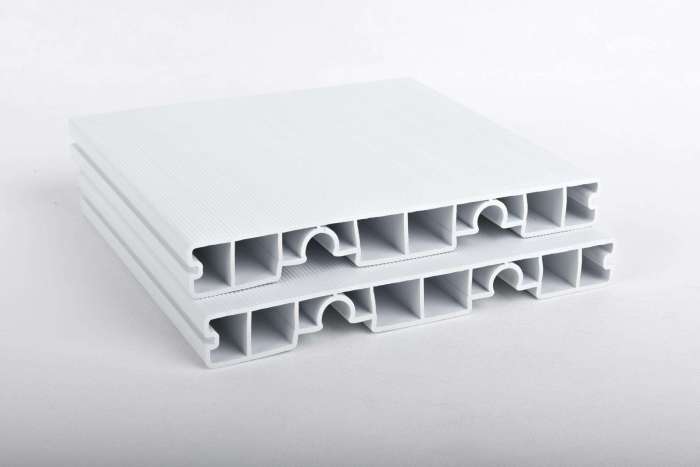

PVC Door Panel Machine

Process:

1. Extruder 2. PVC profile moud 3. vacuum calibration table

4. haul-offs& cutting machine 5. stacker

Description of machines:

PVC Profile&Foamed Extrusion Line is designed for extrusion of PVC plastic doors and windows profile and cross-section cable pipe, aluminum-plastic composite profiles etc. PVC profiles are widely used in the building industry, home and office decoration.

The unit is optimized in design, referring to the newest foreign technology. The unit has the advantages of even plasticizing, small velocity of cutting, high output, long service-life and so on. The unit is composed of conical double-screw extruder, vacuum calibration table, haul off, cutter, foil machine, stackrack, etc. The main machine adopts thefrequency changer or the silicon-controlled rectifier directcrrent velocity modulation.The temperature control meter adopts the import or the joint calital product. The vacuum pump of the auxiliary parts and hauling motor both adopt high-quality products. The maintenance is simple and convenient. The unit is also able to direct extrude artificial wood foamed profile material. The result is better than that of the single-screw extruder. The plastics-steel door and window profile production line adopts conical double-screw extruder, which process PVC door and window profile materials, plastics-steel compound material, multiple-hole wire pipes, decoration profiles and so on.

Technical parameter

Model | YF180 | YF240 | YF300 | YF500 |

Max.width of product(mm) | 180 | 240 | 300 | 500 |

Extruder model | SJSZ55/110 | SJS65/132 | SJSZ65/132 | SJSZ80/156 |

Extruder power(kw) | 22 | 30/37 | 37 | 55 |

Cooling water(m3/h) | 5 | 7 | 7 | 10 |

Compressed air(m3/min) | 0.2 | 0.3 | 0.3 | 0.4 |

Service

Pre-sale service

To provide information and market research,to provide consultation.

-To provide many kinds of conveniences and market service,etc.

-To help customers make the project planning and system requirements analysis.

-To make our products maximum to meet clients' requirements.

-To play the greatest overall economic benefits of customers' investment.

After-sale service

-To install products and test products freely for customers.

-To provide the formulas and technologies of relevant products and the information of chemical materials manufactories.

-To direct technology aspect of relevant use according to customers' requirements.

-To provide technical training for clients' employees.

-To be responsible for maintenance service, door-to-door service under the necessary circumstance.

Packaging & Delivery

Packaging Details

Standard shipping package for WPC Door Frame making machine

Port

Shanghai

Lead Time

Quantity(Sets) | 1 - 1 | >1 |

Est. Time(day) | 45 | To be negotiated |

Technology support

-To provide installation and test for the machine.

-To provide formulas and technology of relevant products.

-To provide information of chemical material manufactories.

-To provide technical training for clients' employees.