SPC Vinyl flooring Production Line

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20sets/month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 92/188 |

|---|---|

| Means of Transport: | Ocean, Land |

| Use: | Others |

| Plastic Type: | PVC |

| Shaft Design: | Double |

| Brand Name: | Kingshine |

| Power: | 110kw |

| Capacity: | 500-750 |

| High capacity: | PLC control system |

| Siemens system: | deeply embossing |

| internation electric parts: | ABB inverter |

| Patent Laminate device: | Automatic Sheet collector |

| Best service: | Highest Tech |

| Production Capacity: | 20sets/month |

| Packing: | Plastic film or wood |

| Delivery Date: | 45days |

Product Description

SPC Vinyl flooring Production Line

Product Description

The SJSZ 92/188 Rigid core flooring SPC flooring extrusion machine/ production line

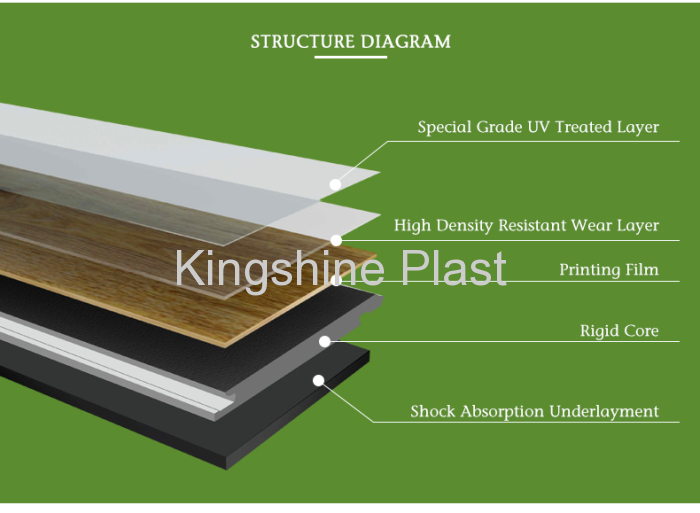

One step extrusion with online decoration film lamination,wear-resisting layer at top and bottom with sound insulation cushion layer

1)Surface can be laminated with different design decoration film

2)Laminate wear-resisting layer at top surface

3)Emboss with different design

4)Sound insulation cushion layer can be laminaed at bottom side

| We are Focus on German SIEMENS electrics for our Rigid core flooring SPC flooring extrusion machine/ production line | |

| Finished Product Size | (970mm)1220mm with thickness:2mm-7mm |

| Main Material | PVC/CaCO3/Processing Additives |

| Extruder | 92/188 Conical Double-Screw Extruder |

| Production Capacity | 800kg/h |

| Air Pressure | 0.6Mpa/min |

| Power Supply | 3P/380V/50HZ |

Rigid core flooring SPC flooring extrusion machine/ production line advantages

1.Inverter is ABB

2.Main Motor/Cutter Motor/AC Contactor/Thermal Overload Relay are Germany SIEMENS

3.PLC is SIEMENS

4.Breaker is SIEMENS from Germany

5.OMRON Japan

6.Origin of ScrewGM/BH/DMJ

7.The mould is designed by our company with the latest technology in China

8.Calibration mould:Thickness is 100mm.and the distance between each pair mould can be adjusted according to the application of board.

9.Material formulation:we can input 100%recycled material.

10.Our Certificates :CE,ISO9001,SGS,TUV

We are the strategic partner relationship with SIEMENS

Production Flow

Rigid core flooring SPC flooring extrusion machine/ production line include

1)SJSZ92/188 Conical twin-screw extruder

2)T type Mould

3)4-roller Calender with online lamination device

4)Cooling Bracket+Air Curtain

5)Side Trimming Device

6)Haul off device

7)Precision shearing machine

8)Stacker

Auxiliary Machines

We provide the Auxiliary Machines of Rigid core flooring SPC flooring extrusion machine/ production line

| No. | Name of Machine | Type | Quantity |

| 1 | Crusher | PS500 | 1 set |

| 2 | Grinder | MF500 | 1 set |

| 3 | Heat/Cooling Mixer | SRL-Z800/2500 | 1 set |

| 4 | Automatic Robot | 1 set | |

Product Uses

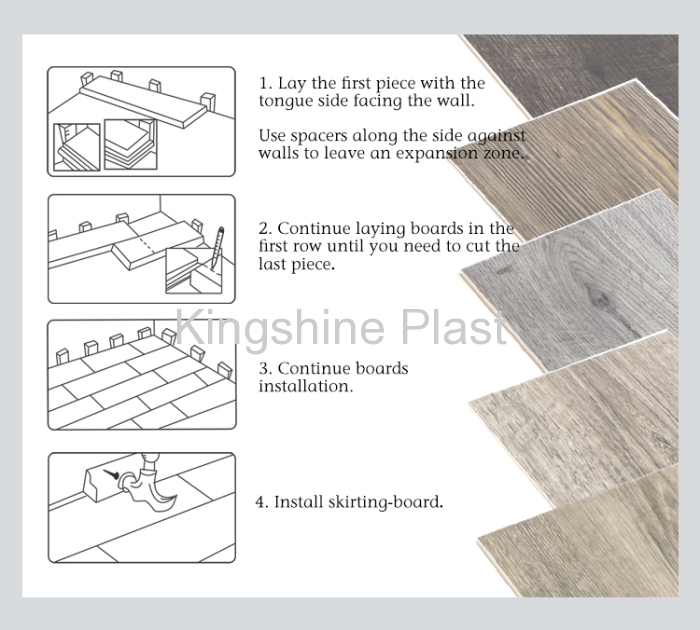

SPC floor is the new environmental Super Floor,adopts the natural stone powder and PVC resin powder as the base material, and is coated with polymer wear-resistant layer, and is processed by Plastic SPC Flooring Click Plank Production Line.The whole process does not use glue, paint and other substances containing formaldehyde . The materials used are non-toxic formaldehyde free, waterproof sterilization, convenient installation, realistic lines, super wear-resistant waterproof, flame retardant and heat resistant, it is representative of twenty-first Century new high-tech ground material. Because of the excellent stability and durability of the SPC floor, this kind of floor has been popular in developed countries in Europe and America.

Kingshine Rigid core flooring SPC flooring extrusion machine/ production line is able to

produce the different thickness with various designs SPC Flooring Click Plank according to your requestments

The SPC Flooring Click Plank produced by Kingshine Rigid core flooring SPC flooring extrusion machine/ production line is widely used in many different lines for various application including:Department Store,Hotel,Restaurant,Bank,Office,Residence etc

Certifications

Why you choose Kingshine

Jiangsu Kingshine Plastic Machinery Co., Ltd. located in wuxi, City,Jiangsu Province,China

We specialize in manufacturing of Rigid core flooring SPC flooring extrusion machine/ production line,One step multi-layer co-extrusion SPC floor machine,One step multi-layer co-extrusion WPC floor machine in China. We have been keeping researching and developing our production line for many years and have improved to the latest generation. Our Plastic SPC Flooring Click Plank Production Line shows superior performance and capacity.

Kingshine is the unique Chinese factory provides the LIFE-LONG service system as we take much attention the feedbacks from our customers

Pre-sale service:

To provide information and market research,to provide consultation,to provide many kinds of conveniences and market service,etc.

The main purpose of pre-sales service is to help customers make the project planning and system requirements analysis. Make our products maximum to meet clients' requirements. Also play the greatest overall economic benefits of customers' investment.

After-sale service:

To install products and test products freely for customers.

To provide the formulas and technologies of relevant products and the information of chemical materials manufactories.

To direct technology aspect of relevant use according to customers' requirements

To provide technical training for clients' employees.

To be responsible for maintenance service, door-to-door service under the necessary circumstance.

Technology support:

To provide installation and test for the machine.

To provide formulas and technology of relevant products.

To provide information of chemical material manufactories.

To provide technical training for clients' employees.