UV Sheet Production Line

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20sets/month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 80/156 |

|---|---|

| Means of Transport: | Ocean, Land |

| Plastic Type: | PVC |

| Use: | Others |

| Shaft Design: | Double |

| Brand Name: | Kingshine |

| Power: | 75KW |

| Capacity: | 500kg/hr |

| PLC Control system: | Siemens electric system |

| ABB inverter: | Best Quality |

| Best service: | Automatic sheet collector |

| Fast delivery time: | Turnkey project |

| Production Capacity: | 20sets/month |

| Packing: | film or wood |

| Delivery Date: | 45days |

Product Description

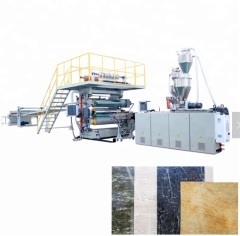

PVC Imitation Marble Decorative sheet Making Machine(PLC Control)

Application

PVC Imitation Marble Table Top/Decorative wall panel making machine

PVC imitation marble Sheet widely used for decorative,such as tile,table top,waist line, door window line, sunshade arc, stair lintel, publicity column frame, frame lines, etc., can be used in high-grade hotels, shopping malls, residential, villa, KTV etc. Building decoration.If you're going to be hone or business place luxury building decoration, imitation marble lines are good options.

PVC imitation marble sheet extrusion machine

Process flow:

Mixer→Spiral loader→SJSZ80 double-screw extruder→Mould→Three-roller calender(online laminating)→Cooling group rollers→Hual off→Transversal cutter→Edge cutter→Conveyor→UV treatment

Other auxiliary equipment(optional):

Name Quantity

SRL-Z type of hot/cool mixer 1set

Crusher 1set

Miller 1set

Air compressor 1set

The difference between pvc artificial marble sheet and real marble sheet:

Real marble will suffer sulfur dioxide and the price is higher.In addition,the surface of artificial sheet could be changed according to customer's request freely.In addition,it is very important that the intallation is very easier and save a lot of labor cost.

PVC is economic and evironment friendly.It will take more market share gradually.

*The lamination is achieved online and don't need any glue or other laminator.After producing this board,if you use UV machine,it would make the board much harder and brighter.

Specification :

Item | 65/132 | 80/156 | 92/188 |

Screw Diameters(mm) | 65mm/132mm | 80mm/156mm | 92mm/188mm |

L/D Ratio | 22:1/25:1 | 22:1/25:1 | 22:1/25:1 |

Output(Kg/h) | 160-200 | 250-350 | 400-500 |

Main Driving Power(kw) | 37 | 55 | 110 |

Heating Powder(Kw) | 4 zones, 20Kw | 5 zones, 38Kw | 6 zones, 54Kw |