High Speed Plastic Mixer

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20sets/month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 500/1000 |

|---|---|

| Means of Transport: | Ocean, Land |

| Use: | Others |

| Plastic Type: | PVC |

| Shaft Design: | Others |

| Brand Name: | Kingshine |

| Power: | 75KW |

| Capacity: | 100-1250kg/hr |

| Siemens Motor: | 304 SS material |

| High capacity: | stable tech |

| Inverter Control: | Automatic system |

| Power save: | internation Electric device |

| Color: | Customer Choice |

| Production Capacity: | 20sets/month |

| Packing: | Plastic film or wood |

| Delivery Date: | 45days |

Product Description

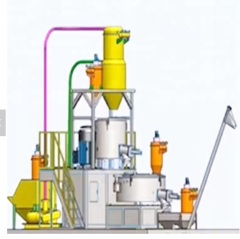

High Speed Plastic Mixer

SRL-Z Series Mixer units are widely used for mixing, drying, and coloring for all kinds of plastic resin such as PVC, PE, PP. They can also be applied in drying of engineering plastic such as, ABS, PC, etc. This unit is composed of heating and cooling mixers. Hot material from heating mixer is fed into cooling mixer for cooling to eliminate gas and avoid burning.

Model/specs | SRL-Z100/200 Hot mixing/ Cold mixing | SRL-Z200/500 Hot mixing/ Cold mixing | SRL-Z300/600 Hot mixing/ Cold mixing | SRL-Z500/1000 Hot mixing/ Cold mixing | SRL-Z800/2500 Hot mixing/ Cold mixing |

Total cubage(L) | 100/200 | 200/500 | 300/600 | 500/1000 | 800/2500 |

Effective cubbage(L) | 65/130 | 150/320 | 225/380 | 375/650 | 600/1050 |

Mixed speed(r/min) | 650/1300/80 | 475/950/80 | 475/950/80 | 430/860/60 | 370/740/50 |

Heating & cooling manner | electric heating self-friction/water cooling | ||||

Mixed time | 8-12 | 8-12 | 8-12 | 8-12 | 8-12 |

Motor Power (Kw) | 14/22/7.5 | 30/42/11 | 40/55/11 | 47/67/15 | 60/90/22 |

Dimension(L*W*H)(mm) | 1950*1600*1800 | 4580*2240*2470 | 4800*2640*2480 | 4600*3000*4050 | 5170*3200*4480 |

Weight(kg) | 2200 | 3400 | 3600 | 4800 | 6200 |

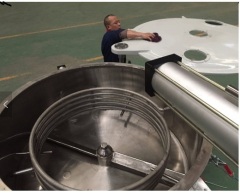

Product Main Photo

Service

Pre-sale service

-To provide information and market research,to provide consultation.

-To provide many kinds of conveniences and market service,etc.

-To help customers make the project planning and system requirements analysis.

-To make our products maximum to meet clients' requirements.

-To play the greatest overall economic benefits of customers' investment.

After-sale service

-To install products and test products freely for customers.

-To provide the formulas and technologies of relevant products and the information of chemical materials manufactories.

-To direct technology aspect of relevant use according to customers' requirements.

-To provide technical training for clients' employees.

-To be responsible for maintenance service, door-to-door service under the necessary circumstance.

Technology support

To provide installation and test for the machine.

To provide formulas and technology of relevant products.

To provide information of chemical material manufactories.

To provide technical training for clients' employees.

Package