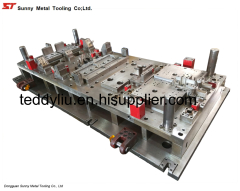

Metal Stamping Tool Die High Strength Steel Progressive Tool Transfer Tool Line Tool-AG004

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | T/T |

| Supply Ability: | 15 sets each month |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Dongguan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | AG04 |

|---|---|

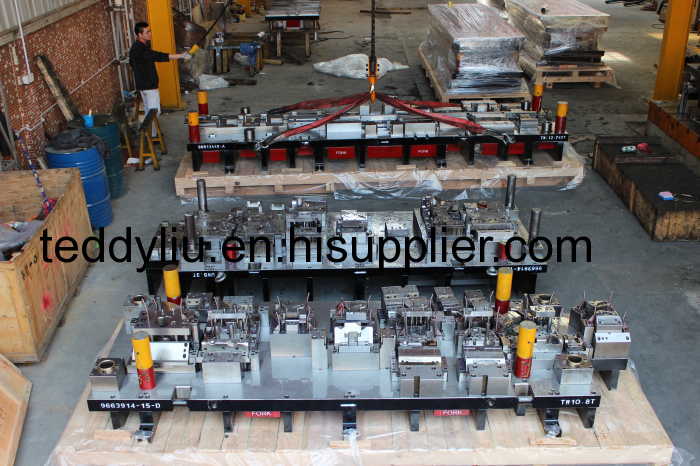

| Means of Transport: | Ocean, Land |

| Product: | Vehicle Mould |

| Product Material: | Metal |

| Shaping Mode: | Punching Mold |

| Brand Name: | Sunnytool |

| Tool Size: | 4200*1800*1000mm |

| Tool Weight: | 12500kg |

| Part Thickness: | 3.0mm |

| Part Quality Control: | CMM |

| Lead Time: | 15 weeks |

| Application: | Car |

| End Customer: | Ford |

| Direct Customer: | Magna |

| Part Material: | Stainless Steel and Aluminum, High Strength Steel |

| Package Method: | Fumigated Wooden Case |

| Production Capacity: | 15 sets each month |

| Packing: | Fumigated Wooden Case |

| Delivery Date: | 12 Weeks |

Product Description

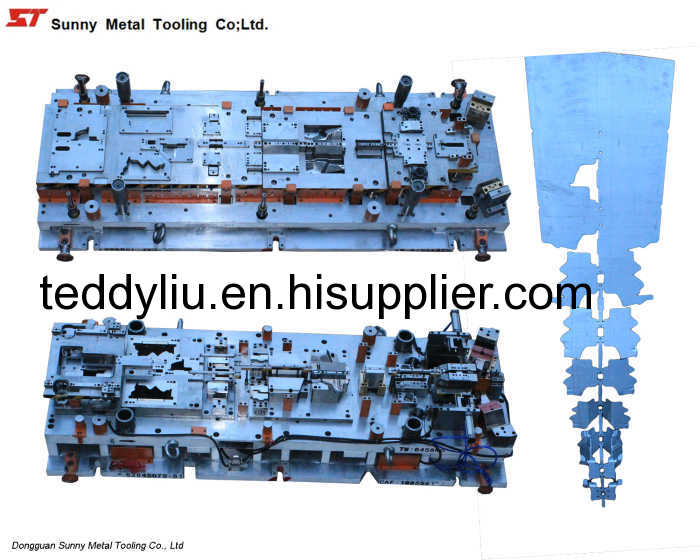

Progressive Die Stamping is a very cost-effective way to make many parts. Material of the proper thickness and width, in coils, is converted into a completed part with each stroke of the press. This is achieved by passing the tail of the coil thru a straightener, into a feed, then thru a die with multiple stations.

The material strip progresses from station to station, where work is changed by notching, percing, drawing, forming as needed. The completed part is then cut-off or blanked thru the die into a container. By this method press operator can perform the work of many with no part handling.

Once the progression strip is fed thru the die, the press runs continuously.

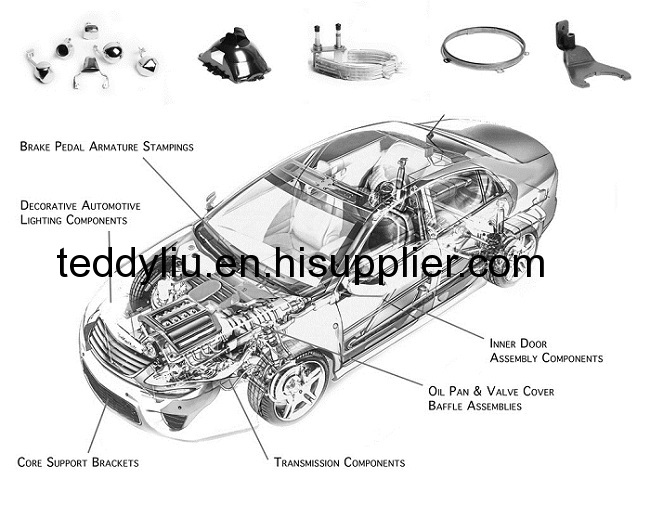

SunnyTool has many years' automotive metal stamping tool manufacturing experience. Our engineers have a thorough understanding of the particular needs and specifications of the automotive industry, and from fuel delivery systems to transmission to brakes, we have the capability to manufacture stamping tools for almost every components required in the automotive industry.

SunnyTool can help manufacture your stamping parts to the most exacting specifications and with the cost efficiency that only an industry leader can provide.

The automotive industry makes use of more deep drawn metal stampings for parts than perhaps any other manufacturing industry today. At SunnyTool we have worked on stampings for dozens of different systems and sub-systems within an array of vehicle platforms.

Just some of the automotive systems in which our engineers are experienced at producing deep drawn parts include:

1.Airbag: metal stampings are used for inflators, diffusers, modules, and initiators.

2.Brake: metal stampings are used for anti-lock brake systems (ABS), foundation brakes, parking brakes, brake modules, brake ECUs, mounting isolator grommets, covers and caps.

3.Cooling System: metal stampings are used for thermostats, fittings, connectors, housings, shells and flanges.

4.Emissions / Pollution Control: metal stampings are used for oxygen sensors, oxygen sensor wire harnesses, EGR, urea injection and shields.

5.Fuel Delivery: metal stampings are used for fuel rail, direct injection, fuel pump, fittings, injector cups, caps, shells, and housings.

6.Lighting: metal stampings are used for bayonet sockets, reflectors and shields.

7.Motor: metal stampings are used for motor housings and armatures.

8.Sensor: metal stampings are used for sensor housings and core tubes.

9.Power Outlets: metal stampings are used for sockets and accessory power sub-systems.

10.Transmission & Chassis: metal stampings are used for rotary valves, valve bodies, valve inlets, valve seals, valve actuators and bonded piston stampings.

Within every one of these systems and sub-systems are a host of possible part types, materials and specifications. Sunnytool has worked with automotive stampings for the smallest vehicles to the largest and everything in between. We understand the demands of automotive parts and the constantly changing needs of the automotive industry.

With complete equipments and unparalleled expertise in the automotive industry, SunnyTool is the automotive metal stamping industry leader.