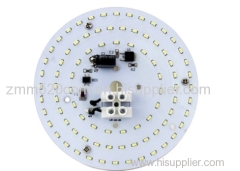

2 Layer Aluminum PCB Printed Circuit Board for LED and pcb fabrication service company

| Min. Order: | 1 Square Meter |

|---|---|

| Payment Terms: | Paypal, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 1500squire meter/week |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Shenzhen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | customized |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Hitech |

| Base Material: | Aluminum |

| Copper Thickness: | 1OZ |

| Board Thickness: | 1.6mm |

| Min. Hole Size: | 0.35mm |

| Min. Line Width: | 0.14mm |

| Min. Line Spacing: | 0.14mm |

| Surface Finishing: | ENIG |

| Solder mask: | Green,Black,Blue,Red |

| Wrap and twist: | 5% |

| Profiling punching: | Routing, V-CUT, Beveling |

| Testing: | 100% E-Test |

| Standards: | IPC-A-610 E Class II-III |

| Mounting Production: | 6 SMT Lines |

| Through Hole Production: | 2 DIP Lines |

| Enclosure Assembly: | 2 Assembly Lines |

| Package: | Vacuum Skin Double-Sided |

| profiling punching: | Routing, V-CUT, Beveling |

| Production Capacity: | 1500squire meter/week |

| Packing: | 35*26*12mm/carton |

| Delivery Date: | 5-8 WDs |

Product Description

2 Layer Aluminum PCB Printed Circuit Board for LED and pcb fabrication service company

Why us?

1.We are PCB & PCB assembly manufacturer with 12 years experience

2.UL&Rohs&ISO9001 certificated

3.4 times 100% QC inspection before Shipping.

4. Profeesional one-stop service release your energy to focus on design and marketing.

5.First order delivery time is around 15days, next order we will produce enough goods in stock for long cooperation.

6.Sign NDA to keep your design safe.

Company Information:

Hitech focuses on high-mix, low volume and quick turn pcb service. With a special market position and excellent corporate culture, we can provide "One-stop shop" service from 1 to 26 layers of PCB products, which includs double layers PCB, Multilayer PCB, Aluminium PCB (Metal core PCB) Flexible PCB (FPCB), Rigid-Flex PCB (Flex-rigid PCB), High Density Interconnect (HDI )PCB boards, heavy copper boards, buried Capacitance & resistance boards, etc. Our products cover various products are exported to Europe, America and Asia.

Detailed specification of manufaturing capacity:

| NO | Item | Craft Capacity |

| 1 | Layer | 1-30 Layers |

| 2 | Base Material for PCB | FR4, CEM-1, TACONIC, Aluminium, High Tg Material, High Frequence ROGERS ,TEFLON, ARLON, Halogen-free Material |

| 3 | Rang of finish baords Thickness | 0.21-7.0mm |

| 4 | Max size of finish board | 900MM*900MM |

| 5 | Minimum Linewidth | 3mil (0.075mm) |

| 6 | Minimum Line space | 3mil (0.075mm) |

| 7 | Min space between pad to pad | 3mil (0.075mm) |

| 8 | Minimum hole diameter | 0.10 mm |

| 9 | Min bonding pad diameter | 10mil |

| 10 | Max proportion of drilling hole and board thickness | 1:12.5 |

| 11 | Minimum linewidth of Idents | 4mil |

| 12 | Min Height of Idents | 25mil |

| 13 | Finishing Treatment | HASL (Tin-Lead Free), ENIG(Immersion Gold), Immersion Silver , Gold Plating (Flash Gold), OSP, etc. |

| 14 | Soldermask | Green, White, Red, Yellow, Black, Blue, transparent photosensitive soldermask, Strippable soldermask. |

| 15 | Minimun thickness of soldermask | 10um |

| 16 | Color of silk-screen | White, Black, Yellow ect. |

| 17 | E-Testing | 100% E-Testing (High Voltage Testing); Flying Probe Testing |

| 18 | Other test | ImpedanceTesting,Resistance Testing, Microsection etc., |

| 19 | Date file format | GERBER FILE and DRILLING FILE, PROTEL SERIES, PADS2000 SERIES, Powerpcb SERIES, ODB++ |

| 20 | Special technological requirement | Blind & Buried Vias and High Thickness copper |

| 21 | Thickness of Copper | 0.5-14oz (18-490um) |

Lead Time:

| Lead time for sample | 2~3days for single-side board |

| 4~5days for double-side board | |

| 24~48hours for ugent | |

| Lead time for opening mould | 3~5days for normal mould |

| 5~7days for hard mould | |

| Lead time for mass production | 5~7days for single/double board |

Quotation requirements for PCB and PCB Asssembly project:

- Gerber File and Bom List;

- Quote Quantity;

- Advise your technical requirements for quoting reference;

- Clearly picturers of PCB or PCB Assembly Sample to us for reference;

- Test Mothod for PCB Assembly.

Packaging Details

1.Firstly seal products with hermetic plastic bag vrey well

2.Then using bubble or foam sheet to seperate them

3.Finally paper carton packing