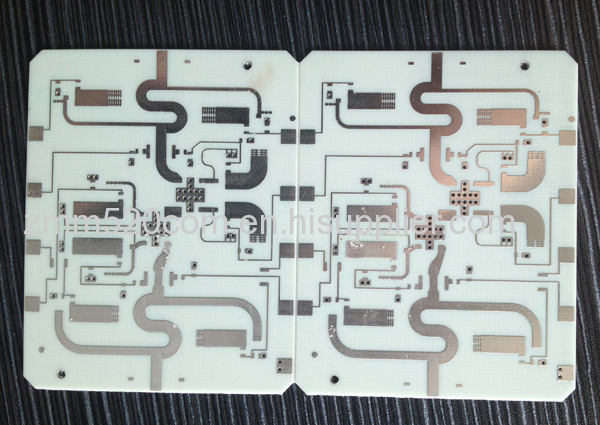

chinese factory professional OEM al2o3 ceramic pcb manufacturer in shenzhen

| Min. Order: | 1 Square Meter |

|---|---|

| Trade Term: | FOB,DAT,DDP,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, L/C, D/P, T/T, WU, Money Gram |

| Supply Ability: | 1500squire meter/week |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Shenzhen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | Customized |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Hitech |

| Base Material: | Al2O3, AIN |

| Copper Thickness: | 0.5oz-4oz |

| Board Thickness: | 0.1mm-3mm |

| Min. Hole Size: | 0.1mm |

| Min. Line Width: | 0.1mm |

| Min. Line Spacing: | 0.1mm |

| Surface Finishing: | HASL,Immersion Gold,OSP |

| Number of Layers: | 2L |

| Solder mask color: | Green,black,Blue,White,Yellow,Red |

| Certificate: | UL, CQC, TS16949, ISO14000, ROH |

| Key Words: | ceramic pcb |

| Testing: | 100% E-Testing |

| Standards: | IPC-A-610 E Class II-III |

| Package: | Vacuum Skin Double-Sided |

| profiling punching: | Routing, V-CUT, Beveling |

| Mounting Production: | 6 SMT Lines |

| Through Hole Production: | 2 DIP Lines |

| Production Capacity: | 1500squire meter/week |

| Packing: | 35*26*12mm/carton |

| Delivery Date: | 5-8 WDs |

Product Description

chinese factory professional OEM al2o3 ceramic pcb manufacturer in shenzhen

Hitech Circuits Co., Limited offers ceramic PCB for yourprinted circuit boards needs. Many users of printed circuit boards find ceramicPCBs have an advantage over traditional boards made of other materials. This is because they provide suitable substrates for electronic circuits that have a high thermal conductivity and a low expansion coefficient (CTE). The multilayer ceramic PCB is extremely versatile and can replace a complete traditional printed circuit board with a less complex design and increased performance. You can use them for high-power circuits, chip-on-board modules, proximity sensors and more.

What can we provide

1.PCB manufacturing from 1 to 32 layers(Rigid PCB,Flexible PCB,Ceramic

PCB,Aluminum PCB);

2.PCB Clone;

3.Component sourcing;

4.PCB Assembly;

5. Write program for customers;

6.PCB/ PCBA Test.

Detailed specification of manufaturing capacity:

NO | Item | Craft Capacity |

1 | Layer | 1-30 Layers |

2 | Base Material for PCB | FR4, CEM-1, TACONIC, Aluminium, High Tg Material, High Frequence ROGERS ,TEFLON, ARLON, Halogen-free Material |

3 | Rang of finish baords Thickness | 0.21-7.0mm |

4 | Max size of finish board | 900MM*900MM |

5 | Minimum Linewidth | 3mil (0.075mm) |

6 | Minimum Line space | 3mil (0.075mm) |

7 | Min space between pad to pad | 3mil (0.075mm) |

8 | Minimum hole diameter | 0.10 mm |

9 | Min bonding pad diameter | 10mil |

10 | Max proportion of drilling hole and board thickness | 1:12.5 |

11 | Minimum linewidth of Idents | 4mil |

12 | Min Height of Idents | 25mil |

13 | Finishing Treatment | HASL (Tin-Lead Free), ENIG(Immersion Gold), Immersion Silver , Gold Plating (Flash Gold), OSP, etc. |

14 | Soldermask | Green, White, Red, Yellow, Black, Blue, transparent photosensitive soldermask, Strippable soldermask. |

15 | Minimun thickness of soldermask | 10um |

16 | Color of silk-screen | White, Black, Yellow ect. |

17 | E-Testing | 100% E-Testing (High Voltage Testing); Flying Probe Testing |

18 | Other test | ImpedanceTesting,Resistance Testing, Microsection etc., |

19 | Date file format | GERBER FILE and DRILLING FILE, PROTEL SERIES, PADS2000 SERIES, Powerpcb SERIES, ODB++ |

20 | Special technological requirement | Blind & Buried Vias and High Thickness copper |

21 | Thickness of Copper | 0.5-14oz (18-490um) |

Equipment List

NO. | Machine Name | QTY | NO. | Machine Name | QTY |

1 | PRESS | 2 | 10 | Exposurer | 5 |

2 | X-Ray | 1 | 11 | Deveoloper | 3 |

3 | Brown-Oxidation | 1 | 12 | Auto V-cut | 1 |

4 | Drilling | 13 | 13 | AOI | 2 |

5 | Cutter | 1 | 14 | Routing | 7 |

6 | PTH | 1 | 15 | ETS | 12 |

7 | PAL | 1 | 16 | Fly Probe | 4 |

8 | PAT | 1 | 17 | YAMAHA SMT | 3 |

9 | Flash Gold | 1 | 18 | FUJI SMT | 4 |

PCB and PCB Assembly Lead time:

Description | Double side | Four Layers | Six Layers | Above Eight | HDI |

Sample | 4 | 7 | 9 | 9 | 12 |

Mass production | 7-9 | 10-12 | 13-15 | 16 | 20 |

Assembly | 7-9 | 15 | 16 | 18 | 25 |

T-SOAR can be trusted PCB Partner, We are waiting for cooperation with you anytime.

- UL, RoHS, ISO, SGS Certification Compliance.

- OEM Assembly, Design, Prototype Service.

- We will be responsible for the quality of our products,

- Survive by quality, Win by Price.

RFQ

Q1:What service do you have?

IBE: We provide turnkey solution including RD, PCB fabrication, SMT, plastic injection & metal, final assembly,testing and other value-added service.

Q2:What are the main products of your PCB/PCBA services?

IBE: Our PCB/PCBA services are mainly for the industries including Medical, Automotive, Energy, Metering/Measurements.

Q3:Is IBE a factory or trade company?

IBE: IBE is a factory with PCB factory located in China and SMT assembly factories in both China & USA.

Q4:Can we inspect quality during production?

IBE: Yes, we are open and transparent on each production process with nothing to hide. We welcome customer inspect our production process and check in house.

Q5:How can we ensure our information should not let third party to see our design?

IBE: We are willing to sign NDA effect by customer side local law and promising to keep customers data in high confidential level.

Q6:What files required to get quotation from you?

IBE: For PCB quotation, please provide the Gerber data/files and indication of related technical requirements as well as any special requirement if you have.

For PCBA quotation, please provide Gerber data/ files and also BOM (bill of materials), and if you need us to do function test, please also provide the test instruction/procedure.

Q7:What is standard delivery term?

IBE: Delivery terms of EXW, FCA, FOB, DDU etc. are all available based on each quote.

Q8:How long does it take for PCB quote?

IBE: Normally 24 hours to 48 hours as soon as receive internal engineer evaluate confirmation.

Q9:Do you have any minimum order quantity (MOQ) requirement?

IBE: No, we do not have MOQ requirement, we can support your projects starting from prototypes to mass productions.

Quote Requirements for PCB and PCB Assembly project:

- Gerber File and Bom List;

- Quote Quantity;

- Advise your technical requirements for quoting reference;

- Clearly picturers of PCB or PCB Assembly Sample to us for reference;

- Test Mothod for PCB Assembly.