Ceramic coated pipe is a carbon steel pipe with multiple, thin layers of ceramic coating both outer and inner. The ceramic coating is resistant to slag attack and extends the life of the pipe when it is immersed into molten metal or in high temperature atmospheres. The applications include powder injections, tap-hole cleaning and opening nozzles in ladles, tundishes and launders. Ceramic coated pipe is a carbon steel pipe with multiple, thin layers of ceramic coating both outer and inner. The ceramic coating is resistant to slag attack and extends the life of the pipe when it is immersed into molten metal or in high temperature atmospheres. The applications include powder injections, tap-hole cleaning and opening nozzles in ladles, tundishes and launders. |

| Ceramic coated pipe was developed to increase the lance life beyond conventional calorized or black pipes. Due to innovative methods of refractory deposition for interior and exterior coatings, it provides unequaled lance life at lower cost. A special ceramic coating has been developed for copper smelter applications. |

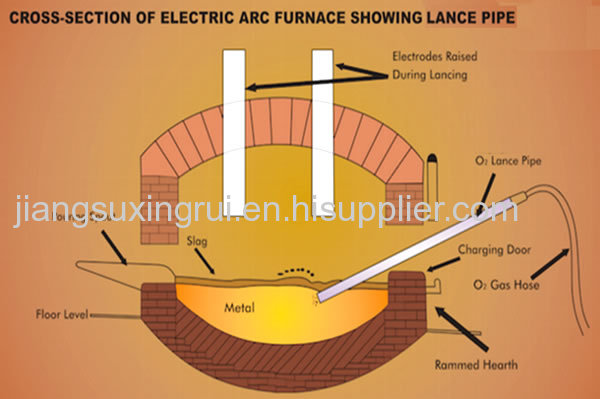

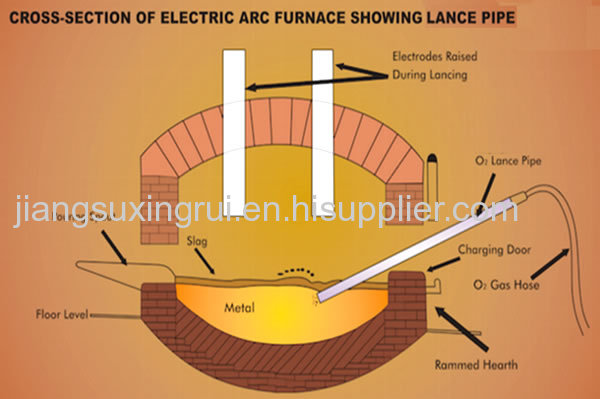

| Ceramic coated pipe is used to inject oxygen or other into the submerged electric furnaces. The pipe provides a much longer life in the high-temperature furnace environment than previously used stainless-steel pipes. Using Ceramic coated pipe to inject gas in submerged electric furnaces reduces costs and downtime for smelter production. |

Some of the various uses of Ceramic coated pipes include the following:

•-Cutting scrap, raising bath temperatures and decarburizing

•-Opening nozzles in tundishes and ladles

•-Injecting carbon and other powders into the electric furnace and ladle

•-Opening the iron notch of a blast furnace

•-Injecting argon into ladles

•-Injecting argon and oxygen into the aod

•-Injecting flux for degassing in aluminum melting furnaces

|

Ceramic coated pipe is a carbon steel pipe with multiple, thin layers of ceramic coating both outer and inner. The ceramic coating is resistant to slag attack and extends the life of the pipe when it is immersed into molten metal or in high temperature atmospheres. The applications include powder injections, tap-hole cleaning and opening nozzles in ladles, tundishes and launders.

Ceramic coated pipe is a carbon steel pipe with multiple, thin layers of ceramic coating both outer and inner. The ceramic coating is resistant to slag attack and extends the life of the pipe when it is immersed into molten metal or in high temperature atmospheres. The applications include powder injections, tap-hole cleaning and opening nozzles in ladles, tundishes and launders.