NP - AF Vertical Slurry Froth Pump

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,DDP,DAP,CIP,CPT,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 100 |

| Place of Origin: | Hebei |

Company Profile

| Location: | Shijiazhuang, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | 2QV-AF |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Type: | Others |

| Application: | Ore |

| Brand Name: | NaiPu |

| Name: | Froth Slurry Pump |

| Type: | Vertical Centrifugal |

| Size: | inch |

| Flow: | 7.2m3/h-330m3/h |

| Head: | 5-30m |

| Material: | Metal or Rubber |

| Metal: | High Chrome A05 A07 A49 |

| Rubber: | R55,R33R08,S01,S12,S42 |

| Trader or Factory: | slurry pump factory |

| Payment term: | TT or LC |

| Production Capacity: | 100 |

| Packing: | wooden case |

| Delivery Date: | 20 dasy |

Product Description

NP - AF Vertical Slurry Froth Pump

Description

Naipu® NP-AF froth

pumps are of heavy duty construction, designed for continuous pumping

of highly abrasive and corrosive frothy slurries. They have a vertical

shaft configuration, and comprise a hopper, with vertical Bearing

Assembly, and Type'NP-AH' pump wet-end. They feature a wide choice of

replaceable abrasion resistant metal or moulded elastomer casing liners

and Impellers.

Typical Applications---

Minerals Flotation Processing

Handle Frothy Slurries

NP-AF FROTH PUMP PERFORMANCE PARAMETERS

Type | Allowable Mating Max. Power(Kw) | Clear Water Performance | Impeller | |||

Capacity/Q m³/hr | Head/m | Speed/rpm | Max Efficiency/% | Impeller Diameter/mm | ||

2QV-NP-AF | 15 | 7.2-33 | 5-30 | 800-1800 | 45% | 229 |

3QV-NP-AF | 20 | 10-104 | 10-28 | 700-1500 | 55% | 268 |

4RV-NP-AF | 40 | 15-130 | 6-28 | 500-1050 | 55% | 397 |

6SV-NP-AF | 75 | 55-330 | 6-25 | 350-680 | 55% | 560 |

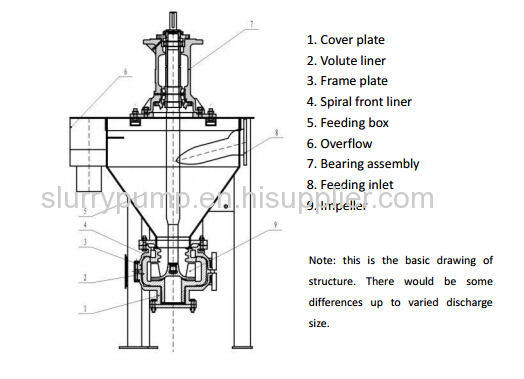

NP-AF Froth Pump Construction Drawing

Materials of Construction

LINERS | IMPELLERS | CASING | BASE | EXPELLER | EXPELLER RING | SHAFT SLEEVE | SEALS | |

Standard |

Chrome Alloy |

Chrome Alloy | SG Iron | SG Iron |

Chrome Alloy |

Chrome Alloy | SG Iron |

Rubber |

Options |

Ferralium |

Ferralium |

SG Iron |

MS |

NI Resist |

NI Resist |

EN56C |

Ceramic |

Company Profile :

ShiJiaZhuang NaiPu Pump Co.,Ltd , Is one of professional factory of slurry pump, sand gravel pump , dredging pump , Water pump and spare parts .

NaiPu Pump is devoted to pump solution industry for more than 30 years!

The Pumps are widely used in in metallurgy, mining, Nonmetallic Mining, Coal, Energy

resources, Sand mining, Dredging, Environmental protection, Petrochemical engineering, Flue gas desulfurization and other industrial departments.

The Pumps are exported to USA, Canada, Germany, Russia , Australia, South Asia, North America, South Africa, and etc , up to more than sixty countries.

NaiPu Main products

1. AH , AHF,Horizontal Slurry Pump

2. SP Vertical sump pump

3. ZJQ Submersible slurry pump

4. G Horizontal sand gravel pump

5. ZJQ Submersible sand pump

6. WS Dredging pump

7. AF Froth Pump

8. TL(R) Desulphurization Pump

8.Clean Water Pump

9. OEM Casting machinery parts

Main Slurry Pump Parts : Impeller , Volute Liner , Casing , ThroatBush, Frame Plate Liner Insert , Cover Plate , Frame Plate, Pump Liner Expeller , Expeller Ring ,Stuffing Box , Expeller , Pump Shaft , shaft sleeve, Shaft Spacer, Bearing Assembly , Base, Stuffing Box, Gland Assembly, Bearing Housing , Lantern Ring , pump discharge pipe , flange , and so on.

Workshop

Naipu Have own Fourdry, Machining , Assembly workshop

Factory Name | Shijiazhuang NaiPu Pump Co.,Ltd |

Manufacturer or Trading Company | Manufacturer |

Workshop | Foundry, Machining, Assembly |

Year the company was established | 2007.01.10 |

Number of employees | 162 |

Designed capacity of factory | 3,000.T Resin Sand 2500T Lost Foam Casting 500T |

Factory area in m2 | 20,000m2 |

Does the factory record rejects. If so what is the reported reject rate for past 12 months. | Yes, We record. the reported reject rate for past 12 months =7.6% |

Quality System Certification | ISO9001-2015 |

Types of Material the company produces | Ductile Iron Chrome Iron Alloy Steel Rubber |

Melting Equipment | Induction 2T X 2 |

Non destructive inspection equipment. | Ultrasonic testing equipment UT

Dye penetrant testing PT |

typical products the foundry makes | Slurry Pump Wet End Parts Hydrocyclone Parts Wear resistant castings |

Minimum and maximum casting weight for each moulding system | Max. 3.0T , Min. 3Kg |

Inspection

All the Horizontal Slurry Pump and Spare Parts will be inspected carefully before delivery

After Sales

We have a team of professional engineers who can help customer to solve any problem during the usage.

The warranty time is 1 years .

All enquiry will get reply within 8 hours.

Welcome to contact me for more