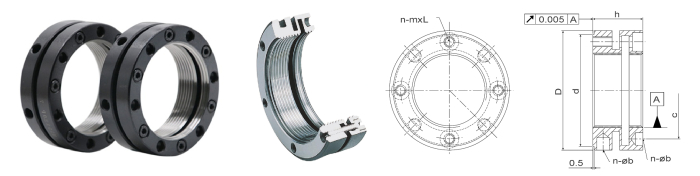

K Series Clasp Locking High Precision Lock Nuts

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Trade Term: | FOB,EXW |

| Payment Terms: | T/T |

| Supply Ability: | 10000 pcs/month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Yancheng, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Service |

Product Detail

| Model No.: | KM/K |

|---|---|

| Means of Transport: | Ocean, Air |

| Product Name: | Precision Lock Nuts |

| Series: | KM/K |

| Features: | Clasp Locking |

| Material: | 42CrMo |

| Hardness: | HRC 28-32 |

| Thread Tolerance: | ISO 4H |

| Manufacturing Method: | High Precision Turning |

| Run Out: | 0.002mm - 0.005mm |

| Surface Treatment: | Alkaline Oxidation (Phosphatizing) |

| Applications: | lathes, grinders, milling machines, motors, shut-off valves, spindle and ball screws |

| Production Capacity: | 10000 pcs/month |

| Packing: | Neutral Packaging |

| Delivery Date: | 20 days |

Product Description

Overview

The important accuracy requirements of a locknut bearing and the V-thread on a ballscrew or spindle are the fitness between the two and the squareness of the end where the locknut attaches the bearing. These factors directly affect the service life, reliability, and quality of the bearings and the ballscrews/spindles; this, of course, also has an effect on the image and quality of your products.

Our High Precision Lock Nuts are specially produced to meet your high demanding requirements.

Technical Details

Product Name: High Precision Lock Nuts, Clasp Locking Precision Lock Nuts

Series: K

Shape: Round

Material: 42CrMo

Hardness: HRC 28-32

Thread Accuracy: ISO 4H

Manufacturing Method: High Precision Turning

Run Out: 0.002mm - 0.005mm

Applications: Ballscrews, High Precision Spindles, etc.

Features:

Our K series Clasp Locking Precision Lock Nuts use the elasticity of the steel body itself, axial lockings and forced locking. The locking capabilities of this series are more than three times higher comapred to the traditional lock nuts. The K series precision lock nuts use 4 to 8 high-strength screws to lock the threads through axial deformation. It is suitable for harsh working conditions where locknuts are easily loosened and high torque is required. The deflection accuracy of the nut can be adjusted by adjusting the tightening force of the axial screws.

Drawing and Data Sheet of K series Clasp Locking Precision Lock Nuts

| Model No./Thread | D | h | d | n - m x L | n | b | c | Max. Nm |

| K M16 x 1.5 | 34 | 18 | 29 | 4 - M4 x 12 | 4 | 4 | 24 | 3.5 |

| K M17 x 1.0 | 37 | 18 | 32 | 4 - M4 x 12 | 4 | 4 | 26 | 3.5 |

| K M18 x 1.5 | 38 | 18 | 33 | 4 - M4 x 12 | 4 | 4 | 28 | 3.5 |

| K M20 x 1.0 | 40 | 18 | 35 | 4 - M4 x 12 | 4 | 4 | 30 | 3.5 |

| K M20 x 1.5 | 40 | 18 | 35 | 4 - M4 x 12 | 4 | 4 | 30 | 3.5 |

| K M22 x 1.5 | 42 | 18 | 37 | 4 - M4 x 12 | 4 | 4 | 32 | 3.5 |

| K M24 x 1.5 | 44 | 18 | 39 | 4 - M4 x 12 | 4 | 4 | 34 | 3.5 |

| K M25 x 1.5 | 45 | 20 | 40 | 4 - M4 x 14 | 4 | 5 | 35 | 3.5 |

| K M26 x 1.5 | 45 | 20 | 40 | 4 - M4 x 14 | 4 | 5 | 35 | 3.5 |

| K M27 x 1.5 | 46 | 20 | 43 | 4 - M4 x 14 | 4 | 5 | 37 | 3.5 |

| K M28 x 1.5 | 46 | 20 | 43 | 4 - M4 x 14 | 4 | 5 | 37 | 3.5 |

| K M30 x 1.5 | 48 | 20 | 45 | 4 - M4 x 14 | 4 | 5 | 39 | 3.5 |

| K M32 x 1.5 | 50 | 22 | 47 | 4 - M4 x 16 | 4 | 5 | 41 | 3.5 |

| K M33 x 1.5 | 50 | 22 | 47 | 4 - M4 x 16 | 4 | 5 | 41 | 3.5 |

| K M35 x 1.5 | 53 | 22 | 50 | 4 - M4 x 16 | 4 | 5 | 44 | 3.5 |

| K M38 x 1.5 | 56 | 22 | 53 | 4 - M4 x 16 | 4 | 5 | 47 | 3.5 |

| K M39 x 1.5 | 56 | 22 | 53 | 4 - M4 x 16 | 4 | 5 | 47 | 3.5 |

| K M40 x 1.5 | 58 | 22 | 55 | 4 - M4 x 16 | 4 | 5 | 49 | 3.5 |

| K M42 x 1.5 | 60 | 22 | 55 | 4 - M4 x 16 | 4 | 5 | 51 | 3.5 |

| K M45 x 1.5 | 68 | 22 | 63 | 6 - M4 x 18 | 6 | 6 | 57 | 3.5 |

| K M48 x 1.5 | 69 | 25 | 65 | 6 - M4 x 18 | 6 | 6 | 58 | 3.5 |

| K M50 x 1.5 | 70 | 25 | 66 | 6 - M4 x 18 | 6 | 6 | 60 | 3.5 |

| K M52 x 1.5 | 72 | 25 | 68 | 6 - M4 x 18 | 6 | 6 | 62 | 3.5 |

| K M55 x 1.5 | 75 | 25 | 71 | 6 - M4 x 18 | 6 | 6 | 65 | 3.5 |

| K M55 x 2.0 | 75 | 25 | 71 | 6 - M4 x 18 | 6 | 6 | 65 | 4.5 |

| K M56 x 1.5 | 75 | 25 | 71 | 6 - M4 x 18 | 6 | 6 | 70 | 4.5 |

| K M58 x 1.5 | 84 | 26 | 79 | 6 - M5 x 20 | 6 | 6 | 70 | 4.5 |

| K M60 x 1.5 | 84 | 26 | 79 | 6 - M5 x 20 | 6 | 6 | 72 | 4.5 |

| K M60 x 2.0 | 84 | 26 | 79 | 6 - M5 x 20 | 6 | 6 | 72 | 4.5 |

| K M62 x 1.5 | 86 | 28 | 82 | 6 - M5 x 20 | 6 | 6 | 75 | 4.5 |

| K M64 x 1.5 | 86 | 28 | 82 | 6 - M5 x 20 | 6 | 6 | 75 | 4.5 |

| K M65 x 1.5 | 88 | 28 | 84 | 6 - M5 x 20 | 6 | 6 | 77 | 4.5 |

| K M65 x 2.0 | 88 | 28 | 84 | 6 - M5 x 20 | 6 | 6 | 77 | 4.5 |

| K M68 x 1.5 | 93 | 28 | 87 | 6 - M5 x 20 | 6 | 7 | 80 | 4.5 |

| K M68 x 2.0 | 93 | 28 | 87 | 6 - M5 x 20 | 6 | 7 | 80 | 4.5 |

| K M70 x 1.5 | 95 | 28 | 89 | 6 - M5 x 20 | 6 | 7 | 82 | 4.5 |

| K M70 x 2.0 | 95 | 28 | 89 | 6 - M5 x 20 | 6 | 7 | 82 | 4.5 |

| K M72 x 1.5 | 97 | 28 | 91 | 6 - M5 x 20 | 6 | 7 | 84 | 4.5 |

| K M75 x 1.5 | 100 | 28 | 94 | 6 - M5 x 20 | 6 | 7 | 87 | 4.5 |

| K M75 x 2.0 | 100 | 28 | 94 | 6 - M5 x 20 | 6 | 7 | 87 | 4.5 |

| K M80 x 2.0 | 110 | 32 | 103 | 6 - M6 x 22 | 6 | 8 | 95 | 4.5 |

| K M85 x 2.0 | 115 | 32 | 108 | 6 - M6 x 22 | 6 | 8 | 100 | 8 |

| K M90 x 2.0 | 120 | 32 | 113 | 6 - M6 x 22 | 6 | 8 | 105 | 8 |

| K M95 x 2.0 | 125 | 32 | 118 | 6 - M6 x 22 | 6 | 8 | 110 | 8 |

| K M100 x 2.0 | 130 | 32 | 123 | 6 - M6 x 22 | 6 | 8 | 115 | 8 |

| K M105 x 2.0 | 135 | 32 | 128 | 6 - M6 x 22 | 6 | 8 | 120 | 8 |

| K M110 x 2.0 | 140 | 32 | 133 | 6 - M6 x 22 | 6 | 8 | 125 | 8 |

| K M115 x 2.0 | 145 | 34 | 137 | 6 - M6 x 22 | 6 | 8 | 130 | 8 |

| K M116 x 2.0 | 145 | 34 | 137 | 6 - M6 x 22 | 6 | 8 | 130 | 8 |

| K M120 x 2.0 | 155 | 36 | 146 | 6 - M6 x 25 | 6 | 8 | 136 | 8 |

| K M130 x 2.0 | 165 | 36 | 155 | 6 - M6 x 25 | 6 | 8 | 148 | 8 |

| K M130 x 3.0 | 165 | 38 | 155 | 6 - M6 x 25 | 8 | 8 | 148 | 8 |

| K M140 x 2.0 | 178 | 38 | 168 | 8 - M6 x 25 | 8 | 10 | 160 | 8 |

| K M140 x 3.0 | 178 | 38 | 168 | 8 - M6 x 25 | 8 | 10 | 160 | 8 |

| K M150 x 2.0 | 190 | 38 | 178 | 8 - M6 x 25 | 8 | 10 | 170 | 8 |

| K M160 x 3.0 | 205 | 40 | 190 | 8 - M8 x 30 | 8 | 10 | 178 | 18 |

| K M170 x 3.0 | 215 | 40 | 203 | 8 - M8 x 30 | 8 | 10 | 193 | 18 |

| K M180 x 3.0 | 230 | 40 | 215 | 8 - M8 x 30 | 8 | 10 | 205 | 18 |

| K M190 x 3.0 | 240 | 40 | 225 | 8 - M8 x 30 | 8 | 10 | 215 | 18 |

| K M200 x 3.0 | 245 | 40 | 233 | 8 - M8 x 30 | 8 | 10 | 223 | 18 |

| K M210 x 4.0 | 265 | 40 | 253 | 8 - M8 x 30 | 8 | 10 | 243 | 18 |

| K M220 x 3.0 | 265 | 40 | 253 | 8 - M8 x 30 | 8 | 10 | 243 | 18 |

| K M220 x 4.0 | 265 | 40 | 253 | 8 - M8 x 30 | 8 | 10 | 243 | 18 |

| K M240 x 3.0 | 285 | 42 | 275 | 8 - M10 x 30 | 8 | 10 | 263 | 18 |

| K M260 x 3.0 | 305 | 42 | 295 | 8 - M10 x 30 | 8 | 12 | 283 | 35 |

| K M260 x 4.0 | 305 | 42 | 295 | 8 - M10 x 30 | 8 | 12 | 283 | 35 |

| K M280 x 4.0 | 325 | 42 | 315 | 8 - M10 x 30 | 8 | 12 | 303 | 35 |

| K M300 x 4.0 | 345 | 42 | 335 | 8 - M10 x 30 | 8 | 12 | 323 | 35 |

Notes:

Non-Standard Precision Locknuts are available upon request.

The above data is for reference only, we may change the specs without prior notice.

1Nm = 10.2kgf.cm = 0.73lb.ft