Customized Water Cooling Tower Drift Eliminator fill

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 10000sheet/month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | Marley |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Respect |

| CAS No.: | Marley-145 |

| Purity: | 100% virgin material |

| width: | 145mm |

| Sheet Spacing: | 24mm 20mm |

| Application: | Water Treament |

| Product name: | MARLEY Drift Eliminator |

| Water flow: | 25~300t/h |

| Production Capacity: | 10000sheet/month |

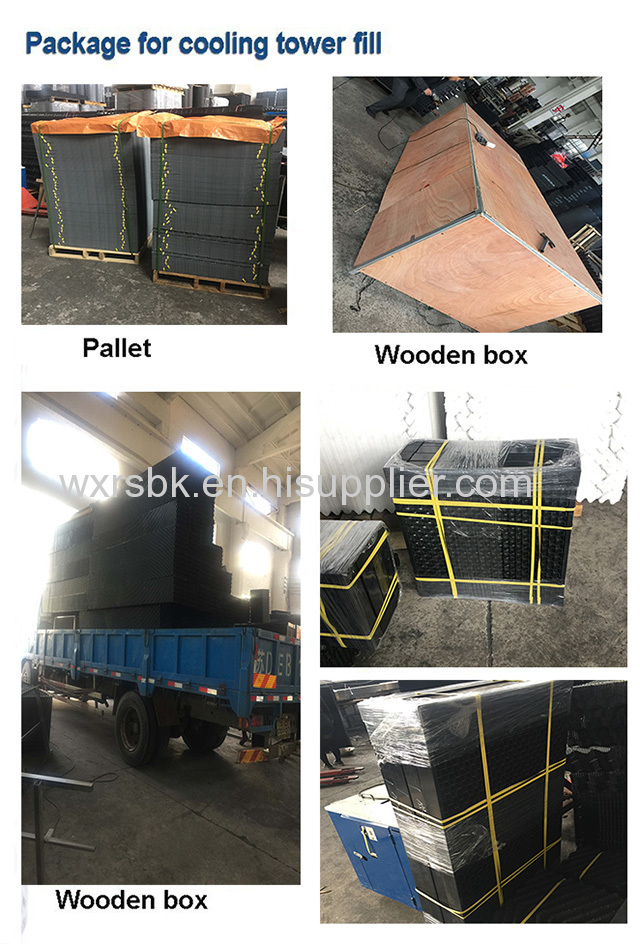

| Packing: | Wooden case/wooden pallet |

| Delivery Date: | 10-15days after payment |

Product Description

Water drift eliminator/Long work life PVC drift eliminator for cooling tower

Drift Eliminators, made out of rigid PVC, are designed to remove entrained particles from air steam efficiently, with minimum pressure drop, thereby reducing the fan power requirement when the air passes through the Drift Eliminator. Water droplets are separated from the air drift at the three direction change points on the drift eliminator.

For Cross flow tower applications, the almost vertical water conduits provided by the CD-100 drift eliminator remove the water droplets out of the drift eliminator area and return them back into the tower and does not allow any re-entry. The special locking pin arrangement for CD-100 facilitates quick and simple assembly at site.

For Counter flow applications, the CD-S130 drift eliminator provides a cellular rugged structure with a very low pressure drop. This results in high drift elimination efficiency while exerting minimum driving force on the fan. The CD-S130 drift eliminators get an S-shaped tubular structure as a result of their fabrication. Individual S-shaped corrugated sheets are bonded with subsequent layers to create the structure. The entire area is thus divided into several fine S shaped mini zones each removing water droplets on the entire surface of the cell.

Drift Eliminator characters:

1. Maximum operational safety;

2. Legal compliance;

3. Original therml performance of your BAC cooling equipment;

4. Easy cleaning;

5. Dry surrouding by minimum drift emission.

Drift Eliminator blade type benefits:

1. Maximum drift capture through efficient design

2. Light weight

3. Easy to handle, lift and remove for inspection and service of water distribution system and heat transfer surface (fill and coil)

4. Nested modules to guarantee watertight seam

5. Corrosion free

6. Perfect fit: model specific size kits

Drift Eliminator More Pictures:

Packaging&Shipping:

Our Advantages: 1. Our products use non-alkali glass fiber as the inner core, coupled with high density polyethylene and imported material as the outer protective layer, it is of high quality and l ow price. 2.Quality, loyalty,and service is our faith! |