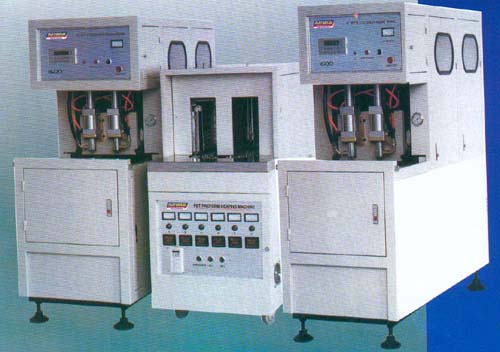

PET Bottle Blow Molding Machine

| Place of Origin: |

Zhejiang |

Company Profile

| Location: |

Hangzhou, Zhejiang, China (Mainland) |

Product Description

This machine can produce 50ml to 2l PET bottles from 2sets of twin-cavity blow molds.Uses infrared heating system with 18units of 600watts/infrared ray lamp to achieve uniform heating effect throughout the PET preform walls.Adjustable heating temperature according to size and characteristics of the preforms.Heating unit has a maximum loading capacity of up to 58 preforms.Heating zones temperature can be controlled as required.Heating lamps can be adjusted in upward/dowmward and forward/backward directions to maximize efficiency and to suit various preform sizes and requirements.Combined production rate of up to 1600 bottles/hour using 2sets of twin-cavity molds.PLC(Programmable Logic Control)system with a"user- friendly"(soft touch)pad.Built-in PLC can memorize and store up to 12sets of bottle blowing data.Precision time-control system to 0.01 of a second.High-quality(Festo&Burket)brands of pneumatic elements are used to ensure efficient and reliable equipment performance.Easy to operate and does not require specialized and highly-complicated training for the operation and maintenance of the machine.Ideal for beverage bottling plants and similar industrial applications.

.jpg)