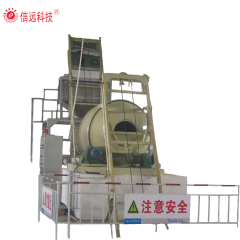

Bulk Blended Fertilizer granular compound fertilizer Production Line

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | Paypal, L/C, T/T, WU, Money Gram |

| Supply Ability: | 100 sets per month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Hefei, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | XYPL |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | xinyuan |

| Number of Raw Material Types: | 4-6 |

| Production Capacity(T/H): | 3-35 |

| Package Type(Kg): | 5-50 |

| Weghing Accuracy: | 0.2% |

| Batching Hopper Volume(M³/Hopper): | 0.2-1.2 |

| Single Time Batching Capacity(Kg): | 50-500 |

| Power (Kw): | 3-30 |

| Automation: | Automatic |

| Certification: | ISO/CE |

| Production Capacity: | 100 sets per month |

| Packing: | wooden case |

| Delivery Date: | 35-60 days |

Product Description

Product features:

Composition of production line:

1. Batching system: including raw material storage silo, automatic feeding device, electric weighing system with hopper,electric control system of batching system

2.Lifting and stirring system: including elevator, multidimensional efficient mixer

3. Quantitative packaging system: including electric quantitative packing machine, conveyor, bag-sealing machine

4. Electric control system: including PLC general control cabinet, customized software, setting display text, cable bridge

Production line series:

1. XYPF SERIES: Feeding on the ground. With capacity of 8t/h, 10t.h, 15t/h, 20t/h, 30t/h available. Machine material can be full 304 Stainless steel or Contact material 304 stainless steel.

2. CZPF SERIES: Vihicular BB fertilizer production with capacity of 3-4t/h.

3. PHB SERIES: Single bag batching with capacity of 5-8t/h, 12-15t/h.

Main features of XYPF series:

1. Feeding on the ground: The materials can be transported quickly and conveniently without feeding elevators.

2. Large output: output per hour 8-30T; A varieties of specifications to choose from

3. Small coverage area: Compact structure with small coverage area and low height

4. Fully automatic: Computer controlled and fully automated production to improve efficiency and reduce labor intensity.

5. High precision: materials are electronically weighed and the proportion is controlled strictly.

6. Good mixing: rolling type mixer, single bucket lifting; Not damaging the original partical shape of the material; meanwhile prevent the segregation of finished product after mixing.

7. Site monitoring: high speed communication interface 485; production line main control room can monitor the status of each device.

Parameters:

| Production line | XYPF-8A | XYPF-10D | XYPF-15C | XYPF-20C | XYPF-30C | CZPF | PHB |

| Fertilizer form | Loose granule, crystal with good fluidity | ||||||

| Number of raw material types | 4-6 | 4-6 | 4-6 | 4-6 | 4-6 | 3-4 | 4-6 |

| Production capacity(T/h) | 8-10 | 10-12 | 15-18 | 20-25 | 30-35 | 3-4 | 5-10 |

| Package type(kg) | 5-50 | 5-50 | 5-50 | 5-50 | 5-50 | 5-50 | 5-50 |

| Weghing accuracy | ±0.2% | ±0.2% | ±0.2% | ±0.2% | ±0.2% | ±0.2% | ±0.2% |

| Batching hopper volume(m³/hopper) | 0.5 | 0.6 | 0.3-1.0 | 0.3-1.0 | 0.4-1.2 | 0.8 | 0.2-0.5 |

| Single time batching capacity(kg) | 350 | 350 | 500 | 500 | 500 | 50 | 50 |

| Power (kw) | 7-10 | 9-12 | 10-15 | 15-20 | 25-30 | 3-5 | 3-6 |

Factory:

Contact: