Fully Automatic BB Fertilizer Packing Line

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100sets/months |

| Place of Origin: | Anhui |

Company Profile

| Location: | Hefei, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | XYPF-10D |

|---|---|

| Means of Transport: | Ocean, Land |

| Type: | Automatic BB-fertilizer producing line |

| Material: | Stainless Steel |

| Numbers of raw material: | 6-8 types |

| single batching capacity: | 350kg-500kg |

| Production Capacity: | 100sets/months |

| Packing: | wooden cage or customrized |

| Delivery Date: | 45days after recieved deposit |

Product Description

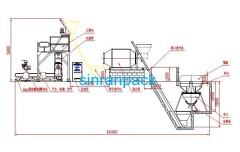

Components of Equipment:

1. Batching System, including raw material storage silo, automatic feeding device, hopper and electronic weighing system, and batching electronic control system.

2.Lift stirring system, including elevator, multidimensional efficient mixer.

3.Quantitative packaging system, including electronic quantitative packaging machines, conveyors, and packet machines.

4.Electric control system, including PLC control cabinet, special software, setting display text, cable tray.

Tech Spec.:

Model Name | XYPF-8A | XYPF-10D | XYPF-15C | XYPF-20C | XYPF-30C | ||

Fertilizer Status | Loose granule, small piece, powder with little water | ||||||

Number of materials | 4-6 types | 4-6 types | 4-6 types | 4-6 types | 4-6 types | ||

Production capacity | 8-10 t/h | 10-12 t/h | 15-18 t/h | 20-25 t/h | 30-35 t/h | ||

Weight range | 5-50kg | 5-50kg | 5-50kg | 5-50kg | 5-50kg | ||

Weighting accuracy | ±0.2% | ±0.2% | ±0.2% | ±0.2% | ±0.2% | ||

Hopper capacity | 0.5m³/EA | 0.6m³/EA | 0.3-1.0m³/EA | 0.3-1.0m³/EA | 0.4-1.2m³/EA | ||

Single batching capacity | 350kg | 350kg | 500kg | 500kg | 500kg | ||

Power AC380V/50Hz | 7-10kw | 9-12kw | 10-15kw | 15-20kw | 25-30kw | ||

Main Functions and Features:

1. Feed on the ground: The raw materials can be transported quickly and conveniently without feeding elevators, fewer feeders and safe operation.

2. Large output: output per hour 8T-30T, a variety of specifications to choose from, fully solve the conflict BB fertilizer due to seasonal concentration of material.

3. Small footprint: set the batching system under machine, the production line structure is compact, small footprint, low height.

4. Fully automatic: Computer controlled, fully automated production, improved efficiency, reduced labor intensity.

5. High precision: Ingredients and packages are electronically weighed and the proportioning is controlled strictly.

6. Good princip: roller type mixing, single bucket lifting, does not damage the original particle shape of the material, but also prevent the segregation phenomenon of the finished product after mixing; intermittent batch mixing method, high mixing uniformity.

7. Site monitoring: high-speed communication interface 485, matching communication systems, production lines main control room can monitor the status of each device consisting of easy connection to the printer, can be stored.

.gif)