As a graphite manufacturer and graphite machining company with more than 25 years experience's experts team, XRD Graphite is your best choice for graphite machining company. We provide precision machining service of graphite and carbon. such as boats, crucibles, continuous casting dies, fixtures, heating elements, blocks, rods, plates, rings, sheets and other graphite parts or products.

We are facilitated to machine most graphite shapes and sizes to meet your different requirements.We understand quality, cost control and precision result are key requirements for our customers . Therefore, XRD graphite will do our best to deliver quality carbon & graphite products and offer the best service. Our highly skilled machinists will make sure your products can be accurately machined. Our graphite production lines ensure stable supply and quality control all the way.

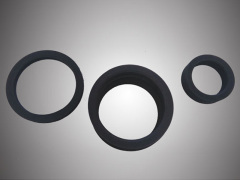

Graphite has excellent self-lubrication, corrosion resistance, wear resistance, low friction coefficient and expansion coefficient, etc. It is often used as a mechanical seal friction pair material. In the machining process of the graphite ring turning, there are frequent chipping, resulting in unsatisfactory product appearance inspection and sealing performance inspection, high product rejection rate and high production cost. This paper analyzes the cause of the edge chipping in the graphite ring turning, and optimizes the tool material, the tool angle, the amount of cutting tool, and the process flow, and solves the chipping problem of turning.

All corners of a mechanical seal graphite ring must not have chipping, and the yield of the seal ring processed by conventional methods is less than 50%. A total of 286 pieces of products were produced using the above-mentioned optimized turning process. Only 32 pieces of turning were found to have a smaller chipping, of which 20 pieces were eliminated in the subsequent face grinding process, and the sealing rings were all tested for airtightness after assembly. ,The product processing pass rate increased to about 96%.

.jpg)