CDSA Cartridge Mechanical seal. AES SEAL CDSA cartridge mechanical seal

| Min. Order: | 2 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT |

| Payment Terms: | L/C, D/A, T/T, WU |

| Supply Ability: | 100 sets/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler, Service |

Product Detail

| Model No.: | FTCT-B |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Standard or Nonstandard: | Standard |

| Style: | Mechanical Seal |

| Material: | Metal |

| Brand Name: | FIT China |

| Function: | PUMPS |

| TYPE: | DOUBLE CARTRIDGE SEALS |

| Production Capacity: | 100 sets/Month |

| Packing: | Carton |

| Delivery Date: | 25 days |

Product Description

Replace AES CDSA Double Cartridge Mechanical seal

This modular seal is ideal for the containment of hazardous process fluids. It's flexible design allows use as a double seal (high pressure barrier fluid) or tandem seal (low pressure barrier fluid) which reduces the neccessity to inventory two seal designs.

The high quality AES CDSA double cartridge mechanical seal for pump that we sell is of high precision, good performance and competitive price.

pecifications

This cartridge seal applies to heat oil pumps in all technical conditions of oil refining plants and chemical plants.

Material and operating limits for this cartridge seal:

Sealing face: Graphite, Silicon carbide, Tungsten Carbide

Metal Component: Stainless Steel

The standard seal unit is 316 Stainless Steel with Carbon and Silicon Carbide faces and Viton 'O' rings.

Self aligning faces inboard and outboard

Cartridge design

Available in exotic alloys (Wetted Parts)

Pre-set unit for reliable installation

Double or tandem seal protection

SIze:1"--5"

Double mechanical seal forms the basis of the engineered sealing system.

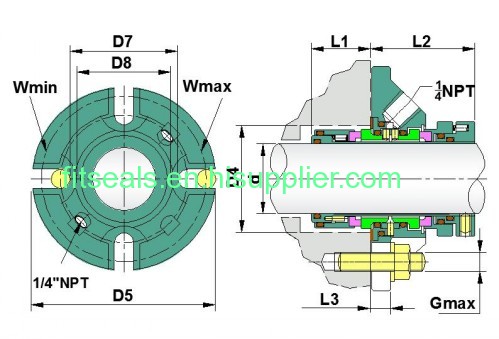

| /Size | D5 | D7 | D8 | L3 | D4 | W | G | L1 | L2 | ||

| (/Metric) | MIN | MAX | MIN | MAX | |||||||

| 24 | 104.8 | 54.0 | 49.2 | 13.2 | 40.0 | 46.0 | 67.0 | 90.5 | 12.0 | 32.5 | 52.4 |

| 25 | 104.8 | 54.0 | 49.2 | 13.2 | 41.0 | 49.0 | 67.0 | 90.5 | 12.0 | 32.5 | 52.4 |

| 28 | 108.0 | 57.2 | 52.4 | 13.2 | 44.0 | 52.3 | 70.3 | 93.6 | 12.0 | 32.5 | 52.4 |

| 30 | 111.0 | 60.4 | 55.6 | 13.2 | 46.0 | 55.5 | 73.5 | 96.8 | 12.0 | 32.5 | 52.4 |

| 32 | 111.0 | 60.4 | 55.6 | 13.2 | 48.0 | 55.5 | 73.5 | 96.8 | 12.0 | 32.5 | 52.4 |

| 33 | 111.0 | 60.4 | 55.6 | 13.2 | 49.0 | 55.5 | 73.5 | 96.8 | 12.0 | 32.5 | 52.4 |

| 35 | 111.0 | 63.5 | 58.8 | 13.2 | 51.0 | 57.5 | 76.6 | 96.8 | 12.0 | 32.5 | 54.0 |

| 38 | 127.0 | 71.5 | 65.0 | 16.4 | 57.2 | 60.3 | 85.7 | 114.3 | 12.0 | 33.3 | 54.0 |

| 40 | 127.0 | 71.5 | 65.0 | 16.4 | 58.0 | 60.4 | 85.7 | 114.3 | 12.0 | 33.3 | 54.0 |

| 43 | 127.0 | 71.5 | 65.0 | 16.4 | 61.0 | 63.5 | 85.7 | 114.3 | 12.0 | 33.3 | 54.0 |

| 45 | 139.7 | 81.0 | 71.4 | 16.4 | 63.5 | 69.9 | 95.3 | 127.0 | 12.0 | 33.3 | 54.0 |

| 48 | 139.7 | 81.0 | 71.4 | 16.4 | 66.7 | 73.0 | 95.3 | 127.0 | 12.0 | 33.3 | 54.0 |

| 50 | 139.7 | 81.0 | 71.4 | 16.4 | 68.0 | 73.0 | 95.3 | 127.0 | 12.0 | 33.3 | 54.0 |

| 53 | 152.4 | 90.5 | 77.8 | 16.4 | 71.0 | 76.0 | 104.8 | 139.7 | 12.0 | 35.0 | 54.0 |

| 55 | 152.4 | 90.5 | 77.8 | 16.4 | 74.0 | 79.4 | 104.8 | 139.7 | 12.0 | 35.0 | 54.0 |

| 58 | 165.1 | 96.8 | 84.1 | 16.4 | 76.2 | 82.5 | 114.3 | 149.2 | 16.0 | 35.0 | 54.0 |

| 60 | 165.1 | 96.8 | 84.1 | 16.4 | 79.4 | 85.7 | 114.3 | 149.2 | 16.0 | 35.0 | 54.0 |

| 63 | 177.8 | 109.5 | 96.8 | 19.6 | 85.8 | 92.1 | 127.0 | 160.3 | 16.0 | 38.1 | 60.3 |

| 65 | 177.8 | 109.5 | 96.8 | 19.6 | 88.9 | 95.3 | 127.0 | 160.3 | 16.0 | 38.1 | 60.3 |

| 68 | 177.8 | 109.5 | 96.8 | 19.6 | 92.1 | 98.4 | 127.0 | 160.3 | 16.0 | 38.1 | 60.3 |

| 70 | 177.8 | 109.5 | 96.8 | 19.6 | 92.1 | 98.4 | 127.0 | 160.3 | 16.0 | 38.1 | 60.3 |

| 75 | 190.5 | 125.4 | 108.0 | 19.6 | 98.5 | 108.0 | 142.9 | 173.0 | 16.0 | 38.1 | 60.3 |

| 80 | 190.5 | 125.4 | 108.0 | 19.6 | 101.6 | 111.1 | 142.9 | 173.0 | 16.0 | 38.1 | 60.3 |

| 85 | 203.2 | 135.0 | 117.5 | 19.6 | 108.0 | 117.5 | 155.6 | 182.5 | 20.0 | 38.1 | 60.3 |

| 90 | 215.9 | 150.8 | 127.0 | 19.6 | 114.3 | 127.0 | 171.5 | 195.2 | 20.0 | 38.1 | 60.3 |

| 95 | 215.9 | 150.8 | 127.0 | 19.6 | 117.5 | 130.2 | 171.5 | 195.2 | 20.0 | 38.1 | 60.3 |

| 100 | 228.6 | 168.3 | 136.5 | 19.6 | 123.9 | 139.7 | 189.0 | 208.0 | 20.0 | 38.1 | 60.3 |

| 105 | 228.6 | 168.3 | 136.5 | 19.6 | 130.1 | 149.2 | 189.0 | 208.0 | 20.0 | 38.1 | 60.3 |

| 110 | 241.3 | 177.8 | 146.2 | 19.6 | 136.5 | 158.8 | 198.4 | 220.6 | 20.0 | 38.1 | 60.3 |

| 115 | 254.0 | 186.6 | 155.8 | 19.6 | 142.9 | 168.3 | 211.1 | 230.2 | 23.0 | 38.1 | 60.3 |

| 120 | 254.0 | 186.6 | 155.8 | 19.6 | 142.9 | 168.3 | 211.1 | 230.2 | 23.0 | 38.1 | 60.3 |

| 125 | 254.0 | 186.6 | 155.8 | 19.6 | 149.2 | 168.3 | 211.1 | 230.2 | 23.0 | 38.1 | 60.3 |

| /Size | D5 | D7 | D8 | L3 | D4 | W | G | L1 | L2 | ||

| (/Inch) | MIN | MAX | MIN | MAX | |||||||

| 1.000 | 4.125 | 2.125 | 1.937 | 0.591 | 1.625 | 1.937 | 2.687 | 3.562 | 1/2 | 1.281 | 2.062 |

| 1.125 | 4.250 | 2.250 | 2.063 | 0.591 | 1.750 | 2.062 | 2.812 | 3.617 | 1/2 | 1.281 | 2.062 |

| 1.250 | 4.375 | 2.375 | 2.187 | 0.591 | 1.875 | 2.187 | 2.937 | 3.812 | 1/2 | 1.281 | 2.062 |

| 1.370 | 4.375 | 2.500 | 2.312 | 0.591 | 2.000 | 2.250 | 3.062 | 3.812 | 1/2 | 1.281 | 2.062 |

| 1.500 | 5.000 | 2.812 | 2.562 | 0.644 | 2.250 | 2.375 | 3.375 | 4.437 | 1/2 | 1.312 | 2.125 |

| 1.625 | 5.000 | 2.812 | 2.562 | 0.644 | 2.375 | 2.500 | 3.375 | 4.437 | 1/2 | 1.312 | 2.125 |

| 1.750 | 5.500 | 3.187 | 2.812 | 0.644 | 2.500 | 2.750 | 3.750 | 4.937 | 1/2 | 1.312 | 2.125 |

| 1.875 | 5.500 | 3.187 | 2.812 | 0.644 | 2.625 | 2.875 | 3.750 | 4.937 | 1/2 | 1.312 | 2.125 |

| 2.000 | 6.000 | 3.562 | 3.063 | 0.644 | 2.750 | 3.000 | 4.125 | 5.437 | 1/2 | 1.380 | 2.125 |

| 2.000-AC | 5.250 | 3.450 | 3.035 | 0.644 | 2.750 | 3.000 | 4.000 | 4.750 | 1/2 | 1.380 | 2.125 |

| 2.125 | 6.000 | 3.562 | 3.063 | 0.644 | 2.875 | 3.125 | 4.125 | 5.437 | 1/2 | 1.380 | 2.125 |

| 2.250 | 6.500 | 3.812 | 3.312 | 0.644 | 3.000 | 3.250 | 4.500 | 5.812 | 5/8 | 1.380 | 2.125 |

| 2.375 | 6.500 | 3.812 | 3.312 | 0.644 | 3.125 | 3.375 | 4.500 | 5.812 | 5/8 | 1.380 | 2.125 |

| 2.500 | 7.000 | 4.312 | 3.812 | 0.769 | 3.375 | 3.625 | 5.000 | 6.312 | 5/8 | 1.500 | 2.375 |

| 2.625 | 7.000 | 4.312 | 3.812 | 0.769 | 3.500 | 3.750 | 5.000 | 6.312 | 5/8 | 1.500 | 2.375 |

| 2.750 | 7.000 | 4.312 | 3.812 | 0.769 | 3.625 | 3.875 | 5.000 | 6.312 | 5/8 | 1.500 | 2.375 |

| 2.875 | 7.500 | 4.937 | 4.250 | 0.769 | 3.750 | 4.125 | 5.625 | 6.812 | 5/8 | 1.500 | 2.375 |

| 3.000 | 7.500 | 4.937 | 4.250 | 0.769 | 3.875 | 4.250 | 5.625 | 6.812 | 5/8 | 1.500 | 2.375 |

| 3.125 | 7.500 | 4.937 | 4.250 | 0.769 | 4.000 | 4.375 | 5.625 | 6.812 | 5/8 | 1.500 | 2.375 |

| 3.250 | 8.000 | 5.312 | 4.625 | 0.769 | 4.125 | 4.500 | 6.125 | 7.187 | 3/4 | 1.500 | 2.375 |

| 3.375 | 8.000 | 5.312 | 4.625 | 0.769 | 4.250 | 4.625 | 6.125 | 7.187 | 3/4 | 1.500 | 2.375 |

| 3.500 | 8.000 | 5.312 | 4.625 | 0.769 | 4.375 | 4.750 | 6.125 | 7.187 | 3/4 | 1.500 | 2.375 |

| 3.625 | 8.500 | 5.937 | 5.000 | 0.769 | 4.500 | 5.000 | 6.750 | 7.687 | 3/4 | 1.500 | 2.375 |

| 3.750 | 8.500 | 5.937 | 5.000 | 0.769 | 4.625 | 5.125 | 6.750 | 7.687 | 3/4 | 1.500 | 2.375 |

| 3.875 | 8.500 | 5.937 | 5.000 | 0.769 | 4.750 | 5.250 | 6.750 | 7.687 | 3/4 | 1.500 | 2.375 |

| 4.000 | 9.000 | 6.625 | 5.375 | 0.769 | 4.875 | 5.500 | 7.437 | 8.187 | 3/4 | 1.500 | 2.375 |

| 4.125 | 9.000 | 6.625 | 5.375 | 0.769 | 5.125 | 5.875 | 7.437 | 8.187 | 3/4 | 1.500 | 2.375 |

| 4.250 | 9.000 | 6.625 | 5.375 | 0.769 | 5.125 | 5.875 | 7.437 | 8.187 | 3/4 | 1.500 | 2.375 |

| 4.375 | 9.500 | 7.000 | 5.750 | 0.769 | 5.375 | 6.250 | 7.812 | 8.687 | 3/4 | 1.500 | 2.375 |

| 4.500 | 9.500 | 7.000 | 5.750 | 0.769 | 5.375 | 6.250 | 7.812 | 8.687 | 3/4 | 1.500 | 2.375 |

| 4.625 | 10.000 | 7.345 | 6.125 | 0.769 | 5.625 | 6.625 | 8.312 | 9.062 | 7/8 | 1.500 | 2.375 |

| 4.750 | 10.000 | 7.345 | 6.125 | 0.769 | 5.625 | 6.625 | 8.312 | 9.062 | 7/8 | 1.500 | 2.375 |

| 4.875 | 10.000 | 7.345 | 6.125 | 0.769 | 5.875 | 6.625 | 8.312 | 9.062 | 7/8 | 1.500 | 2.375 |

| 5.000 | 10.000 | 7.345 | 6.125 | 0.769 | 5.875 | 6.625 | 8.312 | 9.062 | 7/8 | 1.500 | 2.375 |

The CDSA™ cartridge double mechanical seal forms the basis of the engineered sealing system. The standard seal unit is 316 Stainless Steel with Carbon, Tungsten Carbide and Silicon Carbide faces, available with Viton®, Aflas®, EPR and Kalrez® elastomers. This fundamental design is changed through modular component options to suit the requirements of the specific application.

Features:

1. Self-aligning stationary seal-faces with radial contacting pin drive which minimizes damage in stop / start applications and viscous fluids

2. Bi-metal CDSA™ option also includes Exotic Alloy wetted components at minimum price premium for use with corrosive chemicals

3. Hydraulically balanced seal-face technology for reduced power consumption

4. Non-shaft-fretting sleeve elastomer and positive set screw shaft drive

5. Independant seal face design to enhance safe containment of process fluid in the event of damage to any individual sealing element

6. Multiple spring seal face loading

7. Sizes available from 1.000" to 5.000" (24mm - 125mm) in standard and ANSI Plus gland formats larger sizes up to 12.000" (300mm) available on request