Roten Type 5 Mehcanical seal.REPALCE type 7D Mechanical Seal

| Min. Order: | 10 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT |

| Payment Terms: | Paypal, L/C, T/T, WU, Money Gram |

| Supply Ability: | 200 Sets/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler, Service |

Product Detail

| Model No.: | FT7D |

|---|---|

| Means of Transport: | Ocean |

| Standard or Nonstandard: | Standard |

| Style: | Mechanical Seal |

| Material: | Rubber |

| Brand Name: | FIT |

| Function: | for Pump,Compressor |

| Certificate: | ISO9001 |

| Export Area: | Africa,East Asia,Europe |

| type: | conical spring rotor |

| Production Capacity: | 200 Sets/Month |

| Packing: | Carton |

| Delivery Date: | 25days |

Product Description

It is equivalent to TYPE 7D SEALS, UNITEN 5 SEALS.

Roten Mechanical Seal for Water Pump ,Roten Type 5 seal

Materials:

Stationary Ring: (Carbon/SiC/SSiC/TC)

Rotary Ring: (Alumina 99%//SiC//TC)

Secondary Seal: (NBR/EPDM/Viton)

Spring and Punched Parts : (SS304/SS316)

Working Conditions:

Pumps: Water pumps, circulation pumps, etc.

Temperature: -20°C~200°C

Pressure: ≤0.8MPa

Speed: ≤ 10 m/Sec

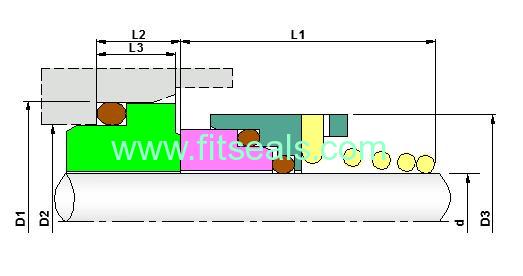

Resilient, conical spring, 'O'-Ring mounted, shaft directional dependent seal

with a stationary to suit DIN housings. The 'O'-Ring mounted seal face offers

enhanced versatility and performance. Type 7D is supplied as standard with a

Type 7D stationary.

Also available as Type 7 in common sizes, with increased "L1" working length and

Type 12 stationary. More details are available upon request.

| Size d | D1 | D2 | D3 | L1 | L2 | L3 |

| 10 | 21 | 17 | 19 | 15 | 7 | 4 |

| 12 | 23 | 19 | 21 | 18 | 7 | 4 |

| 14 | 25 | 21 | 23 | 22 | 7 | 4 |

| 16 | 27 | 23 | 26 | 23 | 7 | 4 |

| 18 | 33 | 27 | 29 | 24 | 10 | 5 |

| 20 | 35 | 29 | 31 | 25 | 10 | 5 |

| 22 | 37 | 31 | 33 | 25 | 10 | 5 |

| 24 | 39 | 33 | 35 | 27 | 10 | 5 |

| 25 | 40 | 34 | 36 | 27 | 10 | 5 |

| 28 | 43 | 37 | 40 | 29 | 10 | 5 |

| 30 | 45 | 39 | 43 | 30 | 10 | 5 |

| 32 | 48 | 42 | 46 | 30 | 10 | 5 |

| 33 | 48 | 42 | 46 | 39 | 10 | 5 |

| 35 | 50 | 44 | 49 | 39 | 10 | 5 |

| 38 | 56 | 49 | 53 | 42 | 13 | 6 |

| 40 | 58 | 51 | 56 | 42 | 13 | 6 |

| 43 | 61 | 54 | 59 | 47 | 13 | 6 |

| 45 | 63 | 56 | 61 | 47 | 13 | 6 |

| 48 | 66 | 59 | 64 | 47 | 13 | 6 |

| 50 | 70 | 62 | 66 | 46 | 14 | 6 |

| 53 | 73 | 65 | 69 | 56 | 14 | 6 |

| 55 | 75 | 67 | 71 | 56 | 14 | 6 |

| 58 | 78 | 70 | 76 | 56 | 14 | 6 |

| 60 | 80 | 72 | 78 | 56 | 14 | 6 |

| 63 | 83 | 75 | 81 | 56 | 14 | 6 |

| 65 | 85 | 77 | 84 | 66 | 14 | 6 |

| 68 | 90 | 81 | 88 | 64 | 16 | 7 |

| 70 | 92 | 83 | 90 | 64 | 16 | 7 |

| 75 | 97 | 88 | 98 | 64 | 16 | 7 |

| 80 | 105 | 95 | 100 | 72 | 18 | 7 |

| 85 | 110 | 100 | 108 | 72 | 18 | 7 |

| 90 | 115 | 105 | 111 | 72 | 18 | 7 |

| 95 | 120 | 110 | 119 | 72 | 18 | 7 |

| 100 | 125 | 115 | 124 | 72 | 18 | 7 |

We take pride in our ability to help customers improve reliability, make a positive

environmental impact and reduce operating expenses. One of our key strengths

is our unmatched ability to deliver engineered seal product orders within 72 hours

of a customer's request. Our worldwide, industry-leading Rotating Equipment

Specialist program educates our engineers through hands-on and theory-based

training courses, ensuring that our customers will receive outstanding service

each and every time they do business with us.