Platinum titanium anode: According to the type of plating / solution composition / solution PH value / working temperature / current density design uniform coating strong adhesion, surface coverage of 100% patented aqueous titanium electroplating platinum process, platinum coating compact structure, the appearance of Was bright silver white, with anode discharge current density, long life and so on. Compared with other titanium-based coated platinum process, the titanium-based platinum plating process is deposited on the surface of the titanium layer of pure platinum coating, titanium-based platinum coating process is coated with a layer of titanium-based compounds containing platinum, After sintering at high temperature, a layer of platinum-containing oxide is formed on the surface of titanium, which has a loose structure, a large resistivity and a large consumption rate during electrolytic discharge. Titanium-based Platinum Plating Titanium Plating is the best choice for plating noble metal.

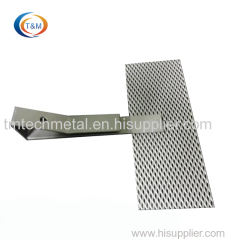

Platinum titanium anode is an insoluble anode, platinum plating and titanium substrate with a solid, stable performance, can replace pure gold, pure platinum anode, for gold and other precious metals plating tank. The appearance of the shape: mesh, plate, tube, rod, filament (minimum diameter of 1 mm), etc., the largest processing size: 1200 × 1500mm; silver white surface, a metallic luster.

Technical characteristics: high current efficiency; excellent corrosion resistance; long electrode life; electrode shape can be designed according to user needs; electrode substrate can be reused several times; no pollution to the medium (electrolysis); can withstand higher Current density.

The Application:Nonferrous Metals Production and Recycling: Electrodepositing produces high purity metals from copper, nickel, diamond and electrolytes; Electroplating: Plating noble metals (gold, silver, rhodium, platinum and ruthenium), surface electroless copper, nickel, zinc, pots, , Chemical Plating on Printed Circuit Boards; Metal Recycling: Wastewater Treatment of Electroplating Solutions; Electrochemical Synthesis: Electrolysis of Mercurial, Seawater Desalination, Production of Persulfate, Regeneration of Oxidants, Treatment of Radioactive Contaminants; Cathodic Protection: Cathodic Protection of Pipelines, Exchanger Cathodic Protection, Marina Steel Construction, Water Pipelines and Sea Water Pump Valves.