Nail Making Die for Z94 Series Nail Making Machine

| Min. Order: | 10 Pair |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 1000 |

| Place of Origin: | Hebei |

Company Profile

| Location: | Cangzhou, Hebei, China (Mainland) |

|---|---|

| Business Type: | Trading Company |

Product Detail

| Model No.: | NM-12 |

|---|---|

| Means of Transport: | Ocean, Air |

| Product Material: | Others |

| Shaping Mode: | Forging Mould |

| Brand Name: | OEM |

| Production Capacity: | 1000 |

| Packing: | AS REQUIREMENT |

| Delivery Date: | 4 WEEKS |

Product Description

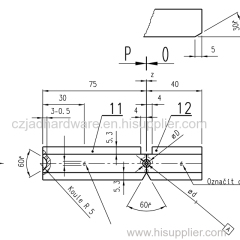

Nail Making Die for Z94 Series Nail Making Machine

Product introduction:

Nail making die as one part of Nail making accessories, there are different shape, different Angle. This Kind is for Z94 series Nail making machine wear and spare parts. We can supply special nail making machine wear and spare parts, just as customer's drawings and requirements.

Product Feature and application:

Doubled tool life

Excellent process security

Automatic force compensation

The two-piece design provides unique breakage protection for clamping inserts, thus helping nail producers to double tool life! Renowned machine producers such as WAFIOS appreciate this. In this Way it is possible to minimise machine downtime

Overview:

Products: nail gripper /nail mould Products NO.: NM12

Place of Origin: Hebei China Product material: Tungsten Carbide Shaping Mode: Forging mould

Trial order: Acceptable Size: Customized

Service: OEM keyword: Nail gripper/Nail making tools/Nail making machine consumable

Product Parameter:

Grade | Equal to | Density | TRS (N/mm2) | Harness | USE |

YG15 | K40 | 14.0 | 2300 | 86.5 | For fabricating drawing dies of steel tubes and rods under high compressibility ratio; punching stamping forging tools under large stress. |

YG15C | K40 | 14.0 | 2500 | 85 | |

YG20 | K40 | 13.5 | 2400 | 84 | For various dies made by cold forging, cold stamping and hot forging. |

YG20C | K40 | 13.4 | 2600 | 81-82 | Dies for wear resistant or impact resistant application |

Product Details:

Drawing:

Product Qualification:

Customized tungsten carbide nail Making die:

1. 100% original Tungsten Carbide material, precision work, high anti-seismic

2. High efficient process. Extending the tool life

3. Options for inserts is in variety types, and really value for money.

4. Deeper precision machining.

| contact me | czjadware201(at)gmail(dot)com | +8615127730093 |