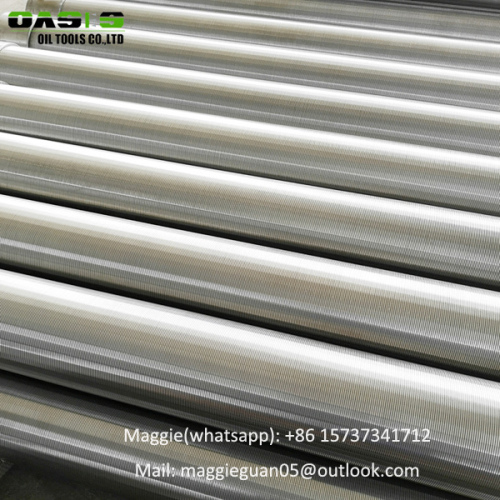

round v wire 0.02mm 1.00mm slot Stainless Steel Johnson Screen/ wedge wire screen

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100000/month |

| Place of Origin: | Henan |

Company Profile

| Location: | Xinxiang, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | 1.00mm slot Stainless Steel screen |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | OASIS |

| Material: | stainless steel 304 316L, carbon steel, |

| Slot Size: | 0.2mm-15mm, Customized |

| Application: | water well screen, filter, mining, coal, petroleum, fertilizer, grain |

| connection type: | weld/thread/flange/plain |

| surface treatment: | galvanzied or coating |

| End Connection: | Plain, Beveled or Thread Coupling |

| Production Capacity: | 100000/month |

| Packing: | as your request |

| Delivery Date: | 10-20days |

Product Description

round v wire 0.02mm 1.00mm slot Stainless Steel Johnson Screen/ wedge wire screen

Wedge Wire Screens are used through out the world for water, oil and gas wells, and for environmental well completions. It is the dominant screen type used in the water-well industry. This type of screen is constructed by winding cold-rolled triangular -shaped wire around a circular array of longitudinal rods. The wire is welded to the rods and produces a rigid unit that has high strength and minimum weight. Wedge wire screen is also well known as continuous-slot wire-wrap screen, Johnson screen, v wire screen, rod based well screens.

| Product Name | OASIS well screen filters stainless steel wire wrapped screen for water well |

| Brand | OASIS |

| OD | 168mm,219mm,245mm,273mm, 340mm, |

| Slot | 1mm |

| Length | 5800mm |

| Material | 304, 304L, 316L |

water filter well screens stainless steel strainer sand tubes

Continuous slot or wire wrap screen

Continuous wire wrap screen is manufactured by wrapping a shaped wire around an internal array of longitudinal rods and are joined by resistance welding. Screen sections are usually twenty feet long(5.8 meter). Most continuous wire wrap screen is manufactured from stainless steel rather than carbon steel in order to avoid problems which often lead to accelerated corrosion.

1.ADVANTAGES

Increased water flow

Reduced energy consumption

Effective and uniform well development

Improved sand control

Reduced pump maintenance

Longer well life

PROVEN PRODUCT OF PROVEN TECHNOLOGY FOR WATER EXTRACTION WORLDWIDE.

2.DESIGN OF WELDED WIRE WRAP SCREENS

The all welded wedge wire screens are made from two elements the V-shaped wedge wire is helically wound around an array of internal longitudinal support rods. Each intersection of wire and rods is automatically resistance welded, creating a very strong cage-like cylinder with one continuous slot spiralling along its full length. The gap between the wires, also called slot or aperture, is manufactured to customer specification, allows water to flow from the surrounding aquifer into the screen, The slots can be very narrow to keep out fine sand grains, which could otherwise damage your pump through abrasion.

Application(Useage):

It can use with the deep well pump, dive the water pump, also may use in the water-treating equipment, the environmental protection, the sea water transforms into the industrial water and life use water desalination treatment, running water treat-ment, water sofrening treatment, the peteoleum industry.

Our company:

Oasis oil tools co.,ltd has been awarded many honors and certifications such as patents of utility model authorized certificate, quality management system certificate, export licence and pre-export licenses. We can design all types of letters of credit according to your requirement. Oasis oil tools co.,ltd has developed into a famous and leading manufacturer which integrate the research and development, design, manufacture and sell. Welcome to visit our company.

Welcome to contact with us for more details: