metal workshop buildings welding structural steel Q235 Q345B steel

| Min. Order: | 100 Metric Ton |

|---|---|

| Trade Term: | CFR |

| Payment Terms: | L/C |

| Supply Ability: | 3000 Ton/per Week |

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 2-729 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | HX |

| Material Grade: | Grade Q235, equivalent to ASTM A36 Grade Q345, equivalent to ASTM A572 |

| Service Offered: | Design, fabrication, packing, transport, erection |

| Surface Treatment: | Painted or HDG or As Customer demand |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Installation: | Engineer are able to stay at site to direct construction. |

| Production Capacity: | 3000 Ton/per Week |

| Packing: | Components will be packaged by steel pallet |

| Delivery Date: | 15 to 40 days |

Product Description

1. Information for metal workshop buildings ( made of steel frame ) :

Standard | ASTM , BS , DIN , GB , JIS |

Material Grade | Q235 & Q345 ( S235JR & S355JR ) |

Dimensions | Yours requirements |

Place Of Origin | Shandong China ( Mainland ) |

FOB Price | US $ 20 - 150 / Square Meter |

Port | Qingdao |

Minimum Order Quantity | 100SQM |

Supply Ability | 1000 Ton / Tons per Month |

Payment Terms | L/C ,T/T |

Quality Control | The third party , SG S , ASIA INSPECTION all accept |

Delivery Term | Within 20 days after signing contract |

Packaging | According yours requirement , usually bundle with steel strip |

Delivery Container | 20'GP , 40'GP , 40'HQ , 40'OT |

Our Experience | Have exported for 13 years , clients from all over the world |

2. Company Data:

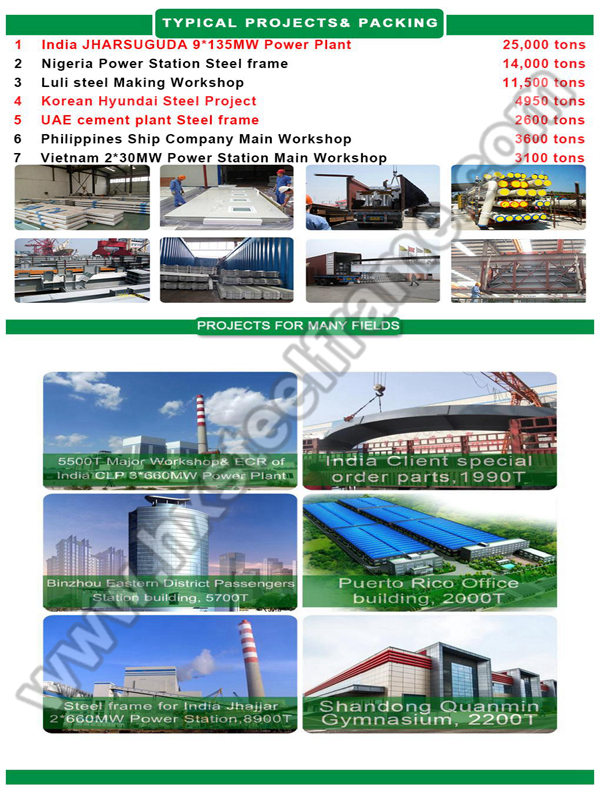

We have been focused on providing integrated steel structure and steel building solutions for the construction builders, design institutes, developers and construction material traders. Established in Shandong, our professional products and services have reached more than 100 countries and regions around the world. We mainly provides major steel structure and steel building solutions including Steel Structure Building,steel workshop& warehouse, Multi-story Building. Currently we have founded branch office and factory in many areas, with over 960 employees worldwide. And the production base is located at Shandong, China. We applies industry-leading environmentally friendly green materials, the world' s leading structural design. Our R&D center was established in Beijing and has applied more than 50 patents including 2 innovation patents up to now. Backed up with over 80 talented engineers in steel structural and architectural design.

3. Project case- Xinwenhua Center Auditorium:

Project Overview:

Fabricate and erect approximately 2500 tonnes of structural steel work. The majority being roof steel work over the auditorium which was supported by four 29m long trusses spanning between the reinforced concrete walls.

The trusses were pre-fabricated in sections and as we were faced with a very tight city centre site it was essential to work very closely with other sub-contractors to plan the on site assembly of the trusses prior to installation.

4. Trial Assemblies to ensure smooth erection of metal workshop buildings ( made of steel frame ) on project site:

Our plant is fitted out with large working areas for major assembly work of steel structures and oversized built-up components

In order to ensure the optimal installation of the steel structures on-site, trial assemblies of various and unique steel pieces with complex geometry forming part of a built-up component, are performed in the plant prior to their delivery to site. In addition to validating the quality of the design, the compliance with engineering parameters and fabrication accuracy, these trial assemblies add great value for the client since they mean potential time and cost savings with regard to installation work on site.

To successfully carrying out trial assemblies of large steel components, our fabrication complexes have been fitted out with large production areas and state-of-the-art equipment as well as measurement method, which are integrated in Tekla Structures 3D software, thus ensuring the quality control of its products.

5. The advantages of metal workshop buildings ( made of steel frame ) :

1) Economic: quick installed and saving the cost of construction.

2) Reliable quality: mainly produced in the factory and control the quality.

3) Big space: the max span of prefab steel structure can reach 80meters.

4) Anti-seismic: because the weight is light.

5) Flexible: can be dismantled and enlarged.

6) Beautiful appearance: can use different colors.

7) Long lifespan: can be used more than 50 years.

6. FAQ:

1) Do you provide on-site installation service for metal workshop buildings ( made of steel frame ) ?

We provides customers with one-stop integrated steel building solution including installation and operation. We have 3 options for on-site installation according to the customer' s specific situation. Firstly, we offer installation instructions and installation video. Secondly, we assign the installation team for the project. Finally, we send professional engineer to guide the local installation team.

2) What' s your delivery time of your metal workshop buildings ( made of steel frame ) ?

Salesman will confirm the time accordingly, large order should communicate with order management department in advance. Normally, delivery time is 45days after receive deposit. Large order delivery time should be arranged separately.