logistic warehouse Pre-engineered Steel Frame S355JR steel

| Min. Order: | 50 Metric Ton |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 8000 Ton/per Month |

| Place of Origin: | Shandong |

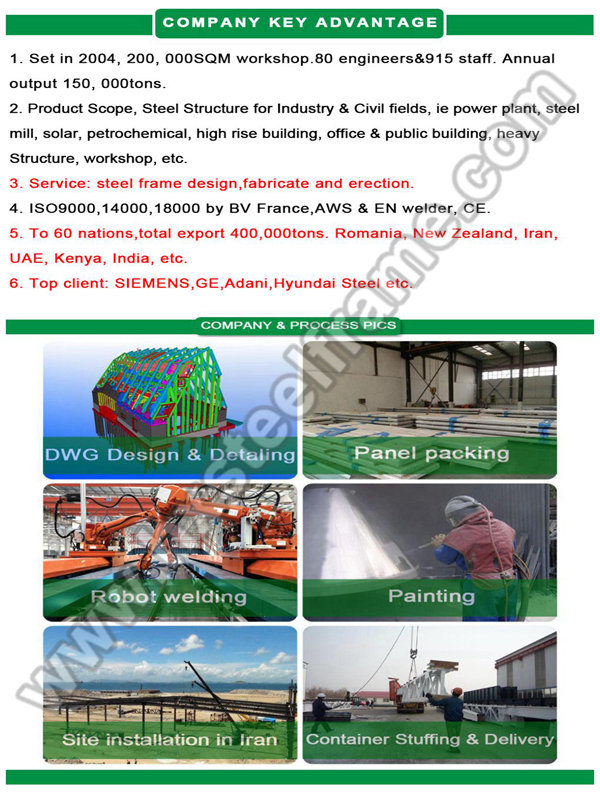

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 2-714 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | HX |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Drawing Design: | by client or by us |

| Service Offered: | Design, fabrication, packing, transport, erection |

| Surface Treatment: | painted with international paint |

| Certificates: | 1. ISO9000, ISO14000, ISO18000 by BV France. 2. EN-1090 CE certificate, American CWI, European TWI, European IWE |

| Production Capacity: | 8000 Ton/per Month |

| Packing: | Sandwich panels covered with plastic film |

| Delivery Date: | 30 days |

Product Description

1. Technical specs for logistic warehouse ( made of steel frame ) :

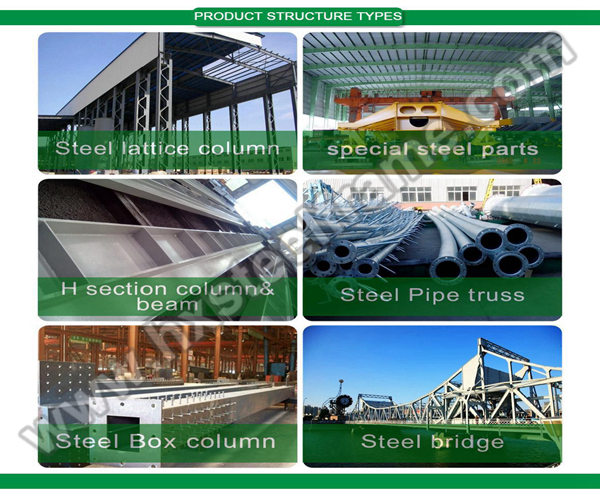

Specification | Structure type | Heavy steel structure |

Design standard | AISI / ASTM / BS / DIN / GB / JIS | |

Length | With customer's requirement | |

Width | Single span , double-span , multi-span | |

Height | With customer's requirement | |

Components | Bolt | Steel grade 45 |

Column | Q235B , Q345B welded H section steel | |

Beam | Q235B , Q345B welded H section steel | |

Tube | Steel Q235B , Q345B | |

High strength bolt | Cr 40 , 10.9S , 9.8S , galvanization | |

Sleeve | Steel Q235B , Q345B , galvanization | |

Purlin | Q235B C channel or Z channel , galvanization | |

Roof & Wall panel | Sandwich panels , Corrugated steel sheet , FRP sheet |

2. Who we are:

We are mainly specially steel structure construction company undertaking the design, fabrication, assembly, and after-sales service of various types of logistic warehouse ( made of steel frame ), civil construction, heavy steel structures, stadiums, industrial workshops and warehouse building, steel structures high-rise building.

Now we have 3 heavy steel production line, six light steel production lines, 3 H-beam secondary processing lines, and advanced digital-controlled multi-head cutting machine,automatic submerged arc welding machine, assembly machine, calibrating machines, full-automatic shot blasting machines, totaling 200 equipment or more.

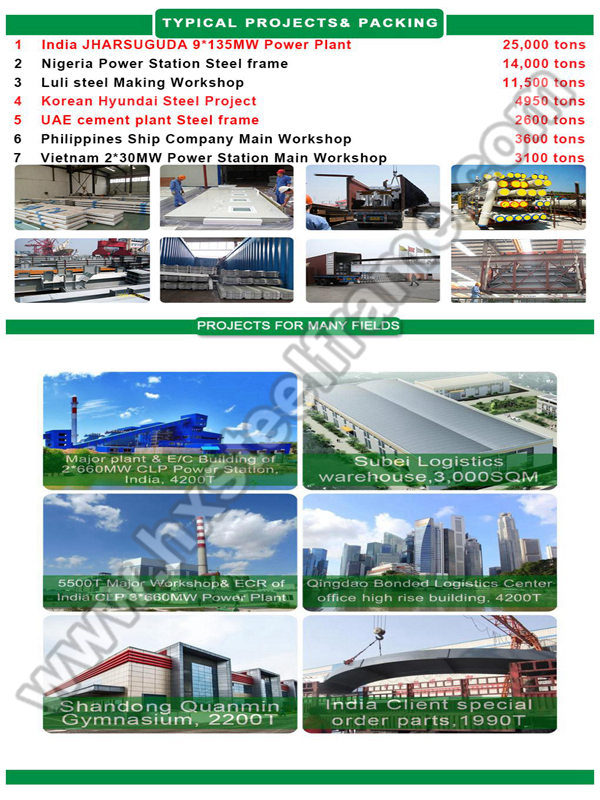

3. Project case- 10000 tons heavy steel structure for Indian cement plant Project:

Description:

The whole steel consumption of this is more than 10000 tons, Among which, the steel consumption of steel roofing truss for steel structure homogenization silo and structural steel bunker is about 7000 tons.

Raw materials silo, clinker materials silo, electricity dust removal, pre-heater and other structures, together with steel structure buildings for subsidiary equipment, total steel structure components reach approximately 3, 000 tons.

4. Hardware advantage for logistic warehouse ( made of steel frame ) :

we are professional for designing and processing steel structure, prefab buildings, workshop, logistic warehouse ( made of steel frame ) , and industrial& civil steel structure etc, you can confidently to place your project to us, and we can offer you with different structure options.

We have plenty of advanced production lines for steel structure and cladding structure, such as the world leading CNC cutting machine with cutting capacity of maximum thickness 200m and the maximum dimension 5m* 28m, which have the function for steel strip cutting and formation optional cutting; Large scale cutting saw can cut the profile for 1250mm, and the large scale three dimensional CNC drilling machine have the drilling capacity for H profile section area 1250mm; The large scale plan CNC drilling machine can drill the maximum 2m*1.6m with maximum thickness 100mm and maximum bore diameter 100mm;

5. Our ERP System and whole production route traceability system for logistic warehouse ( made of steel frame ) :

We have ordered the production ERP system as per its own characteristic, to realize the principle of each component only has one marking.

We realizes Raw Material Traceability System by sticking bar code on raw materials, semi-finished products, finished products and products ready for delivery, establishing systematic database procedures and scanning bar code database through code scanner.

Since the raw material passed the entry inspection and entered the plant, from cutting to painting and then to packing& delivery, the bar code will be transferred and pasted for four times for each part.

Raw Material Bar Code Retrospection

Half Product Bar Code Retrospection

Finished Product Bar Code Retrospection

6. FAQ:

1) How to install logistic warehouse ( made of steel frame ) ?

Reply: We will furnish you the detailed construction drawing and the construction manual which could help you to erect and install the building step by step. We also could send the engineer to your local to help you if need. if you have no work teams, we can send our professional teams to install for you.

2) Storage Life of logistic warehouse ( made of steel frame ) ?

Reply: All steel structure frame life is more than 50 Years, all cladding sheets are about 20 Years.

3) How can you deal with deformation when welding ?

We select suitable welding method, material and sequence as specified material required.