steel structure steel structure fabrication High Strength

| Min. Order: | 120 Metric Ton |

|---|---|

| Trade Term: | CIF |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 9000 Ton/per Month |

| Place of Origin: | Shandong |

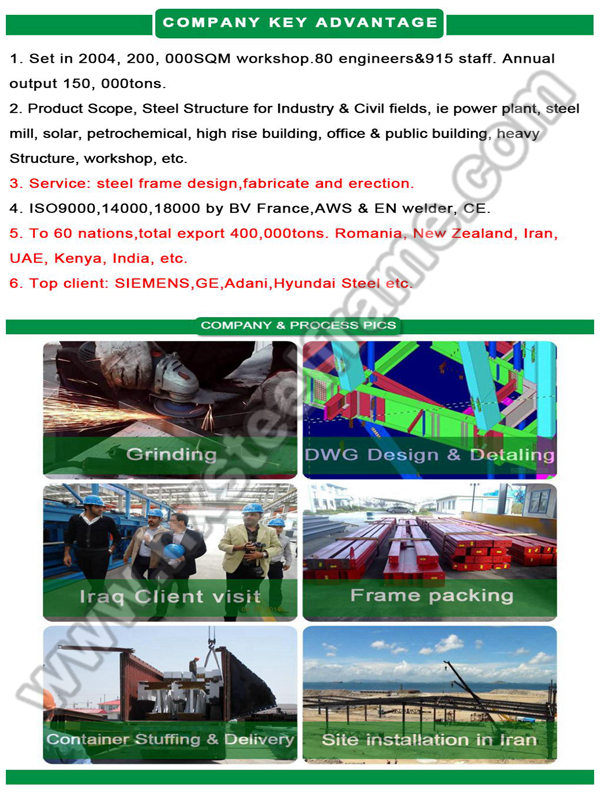

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 2-065 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | HX |

| Service Offered: | Design, fabrication, packing, transport, erection |

| Surface Treatment: | painted with JOTUN |

| Standard: | AISI, ASTM, BS, DIN, GB, JIS |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Certificates: | 1. ISO9000, ISO14000, ISO18000 by BV France. 2. EN-1090 CE certificate, American CWI, European TWI, European IWE |

| Production Capacity: | 9000 Ton/per Month |

| Packing: | Panel accessories will be packaged in wooden box |

| Delivery Date: | usually as customers'order |

Product Description

1. Products description for the Steel building ( made of steel structure ) :

Main Steel | |

Steel Beam Column | Q235B , Q345B |

Secondary Steel | |

Tie Bar | Q235B |

Purlin | C and Z purlin |

Bracing | Q235B |

Accessories | |

Surface | Painted or Hot Dip Galvanized |

Door | Rolling Up Door or Sliding Door |

Window | PVC or Aluminum Alloy |

Roof and Wall Panels | Corrugated Steel Sheet , EPS Sandwich Panel , Rock Wool Sandwich Panel , PU Sandwich Panel |

Others | |

Service | Design , Fabrication and Installation |

We can offer quotations according to customers' drawings and requirements , free design drawings and detailed installation drawings . | |

Design software : Auto CAD , PKPM , MTS , 3D3S , TArch , Tekla Structures ( X steel ) V12.0 , etc | |

Packing | main steel frame with 40 OT roof and panel load in 40 HQ Or According To Customer Requirement |

2. Our company brief :

Our company is the comprehensive enterprise, which gathers the design, processing, production, sale and installation for steel structure. It had passed the certificate of ISO9001:2008 International Quality System and got the Safely Production License. It is located in Shandong province China. The company not only has advanced technique but also has the scientific management system, so the productive force developed rapidly. The company has many production lines for light steel, heavy steel, pipe lines, pressure vessel, steel structure H steel etc. The products adopt high quality raw material from domestic and abroad. The quality and variety of products were in leading position in the same field. It has good prestige. Consequently, our products are selling well in the American, European, Japanese, Asian and the Middle East markets. Due to our quality assurance, competitive prices, and on time delivery, we have developed a large base of repeat customers and got excellent public praise and the best reputation.

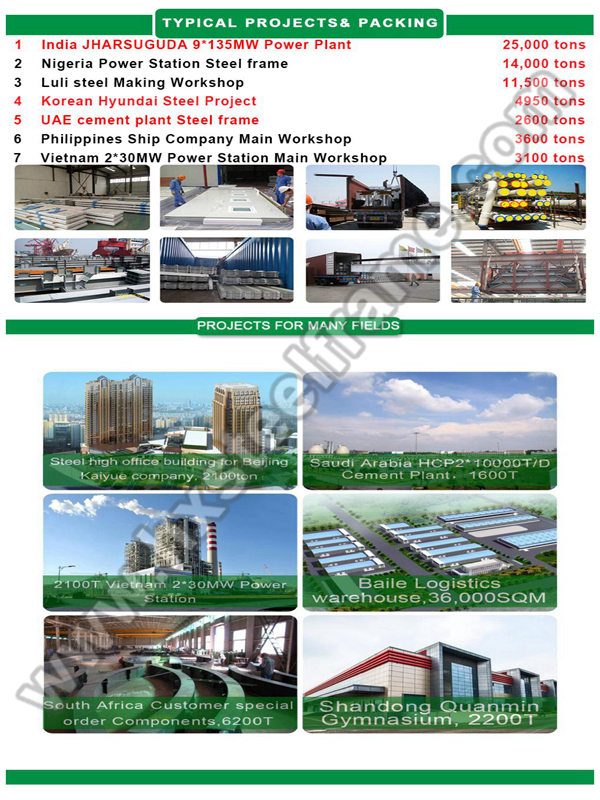

3. Project case- West Chuang Company Steel Structure Workshop / Light steel structure warehouse:

1) Roof: Color-coated Corrugated Steel Sheet with skylight panel

2) Wall: Color-coated Corrugated Steel Sheet

3) Main Steel Framework: Steel Column, Beam, Purlin and other supporting parts with shot blasting and painting process.

4) Material: Q345

5) Window: Plastic Steel Window

6) Door: Sliding Door plus Canopy(all are made by sandwich panel)

7) PVC Downpipe

8) Total 3000tons

4. We are extremely powerful in supplying Complex Steel Structures:

We are good at flexible and versatile production for the fabrication of complex and heavy steel pieces and structures, thanks to:

1) Advanced engineering

2) Proven fabrication processes adapted for carrying out these types of unique products

3) Know-how and long-standing experience in fabrication of complex steel built-ups

4) Lifting capacity of 200 tons for handling fabrication work of heavy steel built-ups

5) Large working areas to carry out assembly work of oversized steel built-ups

6) Important fabrication capacity for large scale projects

The weight and size of these types of products or the combination of these factors can be challenging, especially in terms of handling activities in the plant and transport. As such, certain of the steel built-up components weighing over 60 tons have to be shipped in sections to the construction sites where they will be installed.

5. Packaging& Shipping for Steel building ( made of steel structure ) :

1) All the structure components, panels, bolts and sorts of accessories will be well packed with standard package suitable for ocean transport and loaded into 40' HQ.

2) All the products are loaded at the loading site of our factory using crane and forklift by our skilled workers, who will prevent the goods to be damaged.

3) Good relationship with many vessel companies to make sure the transportation smooth.

6. FAQ:

1) Is there a clear service life of your Steel building ( made of steel structure ) ? If have, how long ?

Under conventional climate and environment, steel structure whole building 30 years, main structure 50 years, protecting system 30 years.

2) What designs do you have in different climates? How can the Steel building ( made of steel structure ) adopt to different climates?

Strong wind region: improve the wind-resisting ability of the internal structure.

Cold region: increase the thickness of the wall, or use good insulation material, improve anti-pressure ability of the structure.

High corrosion region: use corrosion resistant material, or paint anti-corrosive coating.