steel structural fabrication steel structure fabrication low-cost

| Min. Order: | 50 Metric Ton |

|---|---|

| Trade Term: | CFR |

| Payment Terms: | L/C |

| Supply Ability: | 10000 Ton/per Month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 2-062 |

|---|---|

| Means of Transport: | Land |

| Brand Name: | HX |

| Material Grade: | Chinese Q235& Q345B ASTM A36& A992 European S235& S355 |

| Drawing Design: | dwgs Detailing by us |

| Software used: | AUTOCAD 3D3S PKPM Tekla |

| Surface Treatment: | Painted by Zinc rich paint |

| Top client Serviced: | SIEMENS, American GE, FRANCE ALSTOM, French energy power, Vale of Brazil |

| Production Capacity: | 10000 Ton/per Month |

| Packing: | Components will be packaged by steel pallet |

| Delivery Date: | 15 to 40 days |

Product Description

1. Typical Surface treatment for Steel building ( made of steel structural fabrication ) :

Surface Treatment |

Hot dip galvanize |

Standard : JIS , DIN , ASTM B695 - 2000 |

Hot dip galvanizing hole cutting good looking on surface |

Galvanizing process : Steel structural components → Degreasing → Rinsing→ Pickling → Rinsing → Fluxing → Galvanizing → Quenching → (Passivation) → Inspecting → Finished Product |

Paint |

1 . Primer paint one coat 20 - 30 um |

2 . Middle paint two coat 40 - 60 um |

3 . Finish paint one coat 20 - 30 um Paint type : 1 . red primer 2 . zinc primer 3 . Alkyd primer |

2. Why choose us:

1) Workshop covers an area of 200, 000 square meters;

2) Owning 10 professional production lines, annual output reaches 150, 000tons for all kinds of Steel building ( made of steel structural fabrication )

3) More than 80 senior & middle rank engineers; .

4) Products pass the approval of ISO9001, CE, ASME, CWI, SGS, BV etc;

5) Products have already exported to Philippines, Malaysia, Australia, the United States, Chile, the United Arab Emirates, Saudi Arabia, Russia, Niger etc more than 60 countries and regions.

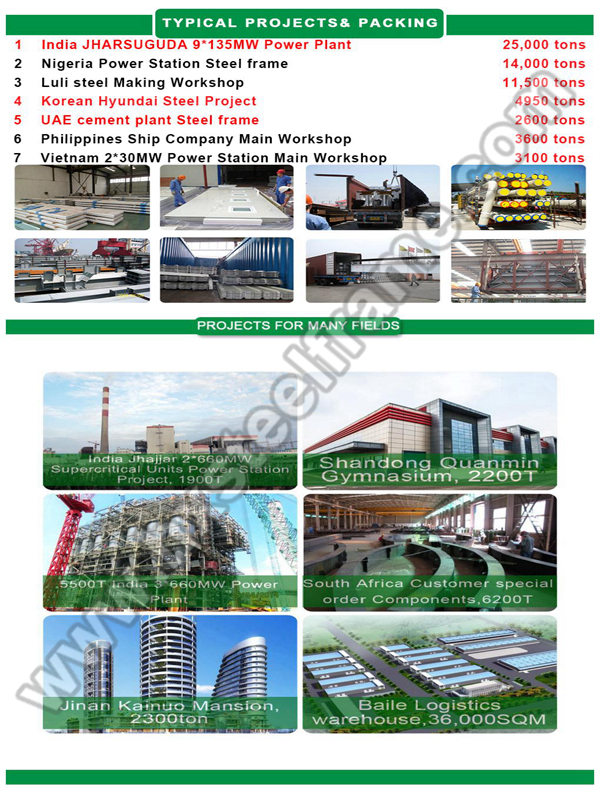

3. Project case- South Africa Light Pre-engineered Building, 7000SQM, 2011:

South Africa workshop project

usage: steel pipe production workshop

length 252M X width 27.5M X height 11M, with a crane of 30 ton, the crane sling height is 7M. The workshop adopt Frame bent structure, lattice form column. Roof and wall surface is single steel sheet, no heat insulation, the bottom of wall has brick wall that 800 mm height and aluminum windows that 1.8m height, skylight sheet on roof for lighting.

Client issue the order to us within 1 week after visit our factory, our hardware and ISO management system leave deep impression to them. Now, we have finished more than 6 orders for this client.

4. DESIGN STANDARD& SOFTWARE for Steel building ( made of steel structural fabrication ) :

Standard: America Standard, Australia Standard, England Standard, China Standard, etc.

Software: SAP2000, Auto CAD, PKPM, RSTAB, PROE, MTS, Tekla Structures( Xsteel) , 3D3S, Tarch, etc.

5. Packing & Delivery for Steel building ( made of steel structural fabrication ) :

For Main Components: Put steel structure components on a steel pallet and tie up the frame part together by packing strap with wood beam and cardboard, then load into container by crane or forklift

For cladding: Plastic film wrap the roof and wall corrugated single steel plate.

but for sandwich panel will load into container piece by piece

This package is to protect the goods from damage, during the transportation.

Delivery:

Load into 40/ 20GP, 40HQ, 40OT or Bulk carrier.

Delivery Time: 15 to 30 days after the receiving deposit or according to client' s requirements.

6. FAQ:

1) Q: How could I control the cost of building a Steel building ( made of steel structural fabrication ) ?

A: Firstly, the designing scheme should be mutually discussed and then accepted. Then, the kinds of building materials should be confirmed since different types and qualities make various prices. After that, we will send you a detailed quotation.

2) Q: How Long does it take to build a Steel building ( made of steel structural fabrication ) ?

A: It depends on the size of the warehouse. Generally, the construction period of is 1 month of a 2000-square-meter workshop by a construction team of 8-10 people. It only costs 2-3 weeks to build the steel structure frame.

3) Q: Is it difficult to build a Steel building ( made of steel structural fabrication ) ?

A: totally not, you can let your local teams build it according to the construction drawings and erection guiding video provided by us.